Product Description

Products Description

Our polyurethane wheels can be widely used for various equipments such as:

1, Material handling equipment (forklift, pallet truck)

2, Airport and CHINAMFG facility

3, Entertainment facility

4, Cleaning machines (sweeper)

5, Production machinery lines

6, Mining

7, Rotating platforms and equipment

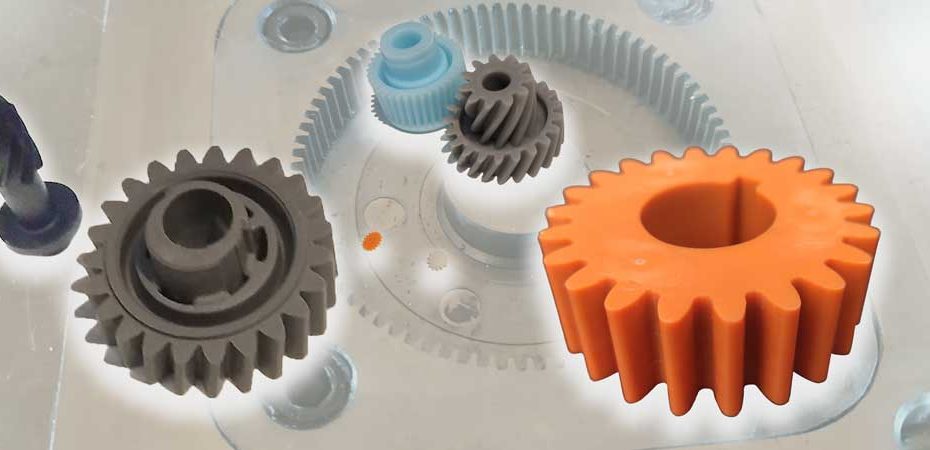

Customized Color, OEM

The Poly Has Strong Bonding To The Steel Wheel

Good Painting To Avoid Corrosion and Rust

Data Sheet

|

BRAND |

PART NO. |

SIZE |

BRAND |

PART NUMBER |

SIZE |

||||||||

|

BT |

163950 |

215*90-60-5hole |

HYSTER |

27705 |

250*1 |

load wheel tophan 84×110 single |

|||||||

|

BT |

162602 |

350*127-80-7hole |

HYSTER |

4065836 |

support 1 |

load wheel 84×95 double |

HYSTER |

1531786 |

load wheel 84×98 single |

||||

|

BT |

143308 |

215*90-60-5hole |

HYSTER |

157 0571 |

drive wheel 254*90-40-5hole |

||||||||

|

BT |

151991 |

310*120-80-7hole |

HYSTER |

1531785 |

load wheel 84×66 single |

||||||||

|

BT |

201332 |

350×140 |

HYSTER |

2791988 |

85×70 double |

||||||||

|

BT |

225145 |

80×74 double |

HYSTER |

1599507 |

support wheel topphan 125х50 |

||||||||

|

BT |

153996 |

350×108 |

HYSTER |

1499033 |

support wheel 350*1 |

150×40 |

HYSTER |

1491574 |

230*75/84 Rubber |

||||

|

BT |

241650 |

support wheel 3 |

230*75/84 Rubber |

||||||||||

|

BT |

138457 |

drive wheel 250х75 |

HYSTER |

457124 |

drive wheel 343×140 |

||||||||

|

BT |

167607 |

load wheel 83х75 |

HYSTER |

1599508 |

support wheel 125×50 |

||||||||

|

BT |

224574 |

load wheel 84х95 |

HYSTER |

1529920 |

1 |

Fork wheel V 85х98 |

HYSTER |

4571574 |

support wheel 285×1=210545 |

Support wheel V 153х76 |

HYSTER |

2 0571 39 |

128*73-62 |

|

BT |

7578683 |

Wheel caster stabilizing support pu 3 |

Wheel drive vu 4 |

load wheel 343×140-7hole |

|||||||||

|

BT |

RRE140-250 FRONT |

350X4 |

drive wheel343х140 |

JUNGHEINRICH |

1 0571 103 |

230*70/82 |

|||||||

|

JUNGHEINRICH |

51115430 |

support wheel 285х1 |

140×54/60-20 |

||||||||||

|

JUNGHEINRICH |

5257174 |

support wheel 380х192 |

CHINAMFG |

813129 |

90×50 |

||||||||

|

JUNGHEINRICH |

51331328 |

drive wheel 343*114 |

CHINAMFG |

CR57179, RA632-4 |

caster 102*64/52 |

||||||||

|

JUNGHEINRICH |

51428172 |

82*70 |

CHINAMFG |

CR1 |

load wheel 230*85 with bearing |

CHINAMFG |

CR115032 |

load 127*73/62 |

|||||

|

JUNGHEINRICH |

5 |

load wheel D85*110 |

CHINAMFG |

127723 |

204*1 |

230*65 |

CHINAMFG |

CR79494 |

13*4.5*8330*114*203 |

||||

|

JUNGHEINRICH |

5257125 |

Drive wheel/D4 |

drive wheel 4 |

drive wheel/D4 |

1 |

85*110/115-25(Axle 25*135) |

CHINAMFG |

003995713 |

load wheel 85х85 |

Packaging & Shipping

Company Profile

Our polyurethane tyre workshop has 10 Lathes including 4 CNC machines, 3 high speed Bandsaws, 10 drilling machines, various other production equipment including a large capacity CHINAMFG blaster. The casting area includes 4 casting machines, 2 long oven baking lines and 20 vertical ovens. The finishing area includes a paint line, assembly presses and engraving machine. The plant has more than 3000 molds covering over 1000 various sizes and has an annual production capacity of approximately 500, 000 pieces.

Why Choose Us

1. OEM Manufacturing welcome: Product, Package…

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. We will inspect each size of wheel before we pack the wheels, and will send you photos to confirm before delivery. After sending, we will track the products for you until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

Cases

Contact Us

Contact Ms Lucy Liu

More Products

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Load Wheel |

|---|---|

| Wheel Material: | PU |

| Brake: | Without Brake |

| Bearing Type: | Ball Bearing |

| Brand: | Wonray |

| Diameter: | 85mm |

| Customization: |

Available

|

|

|---|

Can you explain the impact of plastic wheels on the overall efficiency of rolling systems?

Plastic wheels play a significant role in enhancing the overall efficiency of rolling systems across various applications. Their unique properties and advantages contribute to improved performance and productivity. Here’s how plastic wheels impact efficiency:

- 1. Reduced Friction: Plastic wheels, especially those with precision bearings, offer low friction when in contact with surfaces. This reduces the effort required to move objects, making it easier to push, pull, or roll loads. Less friction also means less energy is expended during operation.

- 2. Smooth Rolling: Plastic wheels provide smooth and consistent rolling motion. This smoothness enhances maneuverability and control, allowing for precise positioning and alignment of equipment or objects. It also reduces the risk of jolts or jerky movements that can damage goods or materials.

- 3. Weight Reduction: Plastic wheels are often lighter than metal alternatives. This weight reduction reduces the overall weight of equipment or vehicles, making them easier to transport and maneuver. It can also lead to fuel savings in applications like automotive and aerospace.

- 4. Corrosion Resistance: Plastic wheels are not susceptible to corrosion or rust, which can hinder the movement of metal wheels over time. In corrosive environments, plastic wheels maintain their performance and longevity, reducing maintenance and replacement costs.

- 5. Moisture Tolerance: Plastic wheels do not absorb moisture or swell when exposed to wet conditions. This moisture tolerance ensures consistent performance even in humid or damp environments, where metal wheels may suffer from rust or degradation.

- 6. Quiet Operation: Plastic wheels are known for their quiet operation. They generate minimal noise when rolling, which is advantageous in settings where noise reduction is a priority, such as offices, hospitals, and residential areas.

- 7. Floor Protection: Plastic wheels are less likely to damage or mark flooring surfaces compared to metal or rubber wheels. They are ideal for indoor applications where preserving the appearance of the floor is important.

- 8. Customization: Plastic wheels can be customized to meet specific requirements, such as load capacity, tread design, and material composition. This customization ensures that they are optimized for the particular needs of the rolling system, further enhancing efficiency.

- 9. Longevity: High-quality plastic wheels are designed for durability and extended service life. Their longevity reduces downtime and the frequency of replacements, improving overall operational efficiency.

- 10. Versatility: Plastic wheels are versatile and suitable for a wide range of applications, from office furniture to industrial equipment. Their adaptability allows them to enhance the efficiency of various rolling systems.

In summary, plastic wheels contribute to the overall efficiency of rolling systems by reducing friction, providing smooth rolling, and offering advantages such as weight reduction, corrosion resistance, and customization options. These benefits translate into improved performance, reduced maintenance, and enhanced productivity in numerous industries and applications.

How does the choice of plastic wheels affect the overall performance and reliability of rolling systems?

The choice of plastic wheels significantly impacts the overall performance and reliability of rolling systems across various applications. Here’s how the selection of plastic wheels influences these factors:

- 1. Load Capacity: The choice of plastic wheels with the appropriate load capacity is essential. Wheels that can adequately support the intended loads ensure the system’s reliability and prevent premature wear or failure due to overloading.

- 2. Material Selection: Different plastic materials offer varying levels of durability, resistance to environmental factors, and chemical resistance. Selecting the right plastic material for the specific application ensures long-term reliability and performance.

- 3. Smooth Rolling: High-quality plastic wheels with precision bearings offer smooth and consistent rolling motion. This smoothness improves the efficiency and reliability of rolling systems, contributing to reduced wear and lower maintenance requirements.

- 4. Noise Reduction: Plastic wheels are known for their quiet operation due to low friction and noise-dampening properties. Choosing plastic wheels with noise reduction features enhances the comfort and usability of the rolling system, particularly in noise-sensitive environments.

- 5. Floor Protection: Plastic wheels are less likely to damage or mark flooring surfaces compared to metal or rubber wheels. This protection ensures the reliability of indoor rolling systems by preserving the appearance and integrity of floors.

- 6. Resistance to Environmental Factors: Plastic wheels can be selected based on their resistance to environmental conditions, such as moisture, chemicals, and temperature extremes. Choosing wheels with appropriate resistance ensures reliable operation in challenging environments.

- 7. Longevity: High-quality plastic wheels are designed for durability and extended service life. They resist wear and degradation, reducing the frequency of replacements and enhancing the long-term reliability of rolling systems.

- 8. Weight Reduction: Plastic wheels are often lighter than metal alternatives. This weight reduction can improve the efficiency of rolling systems by reducing energy consumption, especially in applications like automotive and aerospace.

- 9. Customization: Plastic wheels can be customized to meet specific requirements, including size, load capacity, and tread design. Customization ensures that the wheels are optimized for the unique needs of the rolling system, enhancing overall performance and reliability.

- 10. Safety: Properly selected plastic wheels provide stability and safety to rolling systems, reducing the risk of accidents, equipment damage, and injuries. Reliability in safety-critical applications is paramount.

In summary, the choice of plastic wheels plays a pivotal role in determining the overall performance and reliability of rolling systems. Factors such as load capacity, material selection, smooth rolling, noise reduction, floor protection, resistance to environmental factors, longevity, weight reduction, customization, and safety considerations all influence the system’s ability to operate efficiently and dependably.

How does the design of a plastic wheel contribute to its durability and performance?

The design of a plastic wheel plays a significant role in determining its durability and performance. Several key design factors contribute to these attributes:

- 1. Material Selection: The choice of plastic material is crucial. High-quality plastics, such as polyurethane, polypropylene, and nylon, are commonly used for wheel construction. These materials offer excellent durability, impact resistance, and resistance to wear and tear.

- 2. Load Capacity: The design of the wheel must consider the expected load capacity. Reinforcements, such as ribbing or internal structures, can be added to strengthen the wheel and enhance its load-bearing capabilities. Proper load capacity design ensures that the wheel can support the intended weight without deformation or failure.

- 3. Bearing Type: The design of the wheel includes the type of bearing used. Precision bearings, such as ball bearings or roller bearings, reduce friction and ensure smooth rolling. Properly designed bearings enhance the wheel’s performance by reducing resistance and minimizing wear.

- 4. Tread Design: The tread design on the wheel affects its grip, stability, and noise level. Different tread patterns are used for specific applications. For example, smooth treads provide reduced rolling resistance, while treaded designs offer improved traction. The choice of tread design depends on the intended use.

- 5. Hub and Axle Compatibility: The design of the wheel’s hub and axle connection is essential for secure attachment. It should be compatible with the mounting hardware used in the application. A well-designed hub and axle connection ensure stability and prevent wobbling or detachment during use.

- 6. Resilience: The design should consider the wheel’s ability to absorb shocks and impacts. Resilient plastic materials can withstand sudden impacts without cracking or breaking. This is especially important in applications where the wheel may encounter rough terrain or obstacles.

- 7. Temperature Resistance: Depending on the application, plastic wheels may need to withstand a wide range of temperatures. The design should factor in the material’s temperature resistance to ensure that the wheel remains functional in extreme conditions.

- 8. Size and Dimensions: The size and dimensions of the wheel are critical for load distribution and stability. Properly sizing the wheel according to the application’s requirements ensures optimal performance and durability.

- 9. Corrosion Resistance: In some environments, corrosion resistance is essential. The design may incorporate materials or coatings that protect against corrosion, ensuring a longer service life.

- 10. Wheel Mounting: The method of mounting the wheel to the equipment or vehicle is part of the design. It should be secure and reliable to prevent wobbling or detachment during use.

- 11. Weight Distribution: Proper weight distribution across the wheel is important for even wear and reduced stress on the wheel. Design considerations may include the wheel’s shape and load-bearing capacity to ensure even weight distribution.

A well-designed plastic wheel takes into account these factors to maximize its durability and performance. It should be capable of withstanding the demands of its intended application while providing smooth and reliable movement.

editor by Dream 2024-05-09