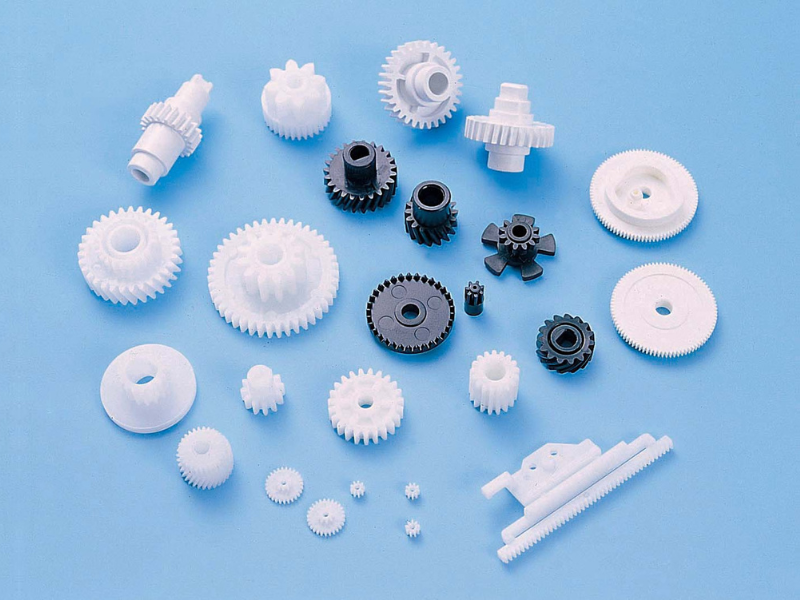

Product Description

Plstic crank wheel with zinc alloy shaft bolt

| Type: | RS-CW01.BS01 |

| Speed ratio: | 1:10 |

| Capacity: | 25kg |

| Material: | Plastic |

| Color: | Black |

CHINAMFG Shutter Component Co., Ltd.specialized in plastic injection,hardware and aluminum products for the rolling shutter accessories like handle crank,side frame,end cap,drive wheel,etc.

Goods in nice quality and competitive price.

Company website: rollmax

Company address:No.18 Bangang Rd,Luotuo Industry Park,HangZhou.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Kind: | Roller Shutter Accessories |

|---|---|

| Structure: | Horizontal |

| Open Type: | Manual |

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

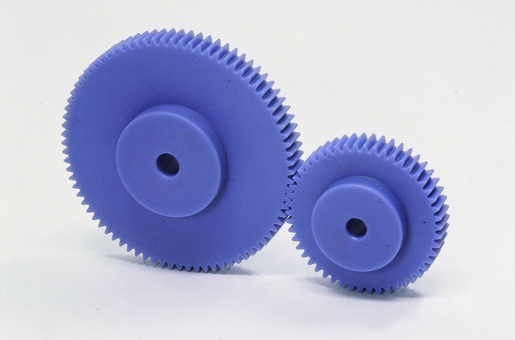

Can plastic wheels be customized for specific uses or environments?

Yes, plastic wheels can be customized for specific uses or environments to meet unique requirements and applications. Customization options for plastic wheels include:

- 1. Material Selection: Plastic wheels can be manufactured from various types of plastics, each with specific properties. Depending on the application, you can choose the most suitable plastic material to optimize factors like durability, chemical resistance, temperature tolerance, and load-bearing capacity.

- 2. Load Capacity: Custom plastic wheels can be designed with specific load-bearing capabilities in mind. Reinforcements and modifications to the wheel’s structure can be made to increase its load capacity, ensuring it can handle the intended weight.

- 3. Wheel Diameter: The size and diameter of the wheel can be customized to match the terrain and space constraints of the application. Whether you need smaller or larger wheels, customization is possible to ensure a perfect fit.

- 4. Tread Design: The tread pattern on plastic wheels can be tailored to provide optimal traction, stability, and noise reduction for specific environments. Different tread designs are available to suit various surfaces and conditions.

- 5. Bearings: Custom plastic wheels can be equipped with different types of bearings to meet performance requirements. Precision bearings, sealed bearings, or special bearing configurations can be chosen based on the application’s demands.

- 6. Environment-Specific Features: Plastic wheels can be customized with features like corrosion-resistant coatings, anti-static properties, UV resistance, and non-marking materials to accommodate specific environmental conditions.

- 7. Color and Aesthetics: Custom plastic wheels can be produced in various colors and finishes to match the aesthetics of the equipment or environment they are used in. This is common in applications like office furniture and consumer products.

- 8. Mounting Options: Custom wheels can be designed with specific mounting and attachment options to ensure a secure fit with the equipment or vehicle. Custom hubs or axle configurations can be provided.

- 9. Specialized Applications: For highly specialized applications, such as aerospace, healthcare, or automotive, plastic wheels can be customized to meet stringent industry standards and certifications.

- 10. Prototyping and Testing: Customization often involves prototyping and testing to ensure that the wheels meet the desired performance criteria. Manufacturers can work closely with customers to develop and refine custom wheel designs.

Customized plastic wheels are valuable for industries and applications with specific needs, ensuring that the wheels perform optimally and contribute to the overall functionality and efficiency of equipment or systems.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

Can you explain the primary functions and applications of plastic wheels in various industries?

Plastic wheels serve essential functions in various industries due to their unique properties and versatility. Here are the primary functions and applications of plastic wheels in different industries:

- 1. Material Handling: Plastic wheels are widely used in material handling equipment, including carts, dollies, and conveyor systems. They provide smooth and noiseless movement, making them suitable for transporting goods in warehouses, factories, and distribution centers.

- 2. Office Furniture: Plastic wheels are commonly found on office chairs and furniture. They allow for easy mobility, quiet operation, and floor protection. These wheels are often made from soft materials like polyurethane to prevent damage to flooring.

- 3. Automotive: In the automotive industry, plastic wheels are used for various applications, including caster wheels on tool carts, wheels for automotive jacks, and even lightweight spare tire wheels. They offer a balance of durability, weight savings, and cost-effectiveness.

- 4. Retail and Shopping Carts: Plastic wheels are a staple in retail and shopping cart applications. They provide smooth and silent movement for shoppers while navigating stores. The lightweight nature of plastic wheels reduces cart weight, making them easier to push.

- 5. Medical Equipment: Plastic wheels are used in medical equipment, such as hospital carts and medical devices. Their non-corrosive properties, lightweight design, and ease of cleaning make them suitable for healthcare settings.

- 6. Aerospace: In the aerospace industry, plastic wheels are used in ground support equipment, maintenance carts, and aircraft cabin service carts. Their lightweight construction is advantageous for handling equipment around aircraft.

- 7. Food and Beverage: Plastic wheels are found in food service equipment, including food carts, serving trolleys, and food processing machinery. They are resistant to moisture and corrosion, which is critical in food handling environments.

- 8. Recreational Vehicles (RVs) and Trailers: Plastic wheels are used in RV leveling jacks and trailer jacks. They provide stability and easy adjustment for leveling RVs and trailers when parked.

- 9. DIY and Home Improvement: Plastic wheels are used in DIY projects and home improvement applications. They can be found on hand trucks, utility carts, and DIY furniture, offering ease of movement and floor protection.

- 10. Marine and Boating: Plastic wheels are used on boat trailers and marine equipment. They resist corrosion from saltwater exposure and offer buoyancy, making them ideal for marine applications.

- 11. Agriculture: In agriculture, plastic wheels are used on farm equipment, including wheelbarrows and agricultural carts. They provide durability and easy maneuverability in outdoor and rugged environments.

Plastic wheels are valued for their lightweight, corrosion resistance, cost-effectiveness, and adaptability across a wide range of industries. They play a vital role in improving mobility, efficiency, and performance in various applications.

editor by Dream 2024-05-14