Product Description

Product Description

| model | Number of poles | Phase | Rated voltage | Rated speed | Continuous locked-rotor torque | Rated torque | Rated power | Peak torque |

| Units | VDC | RPM | N.m | N.m | W | N.m | ||

| 42BYA075B030C-02 | 4 | 3 | 24 | 3000 | 0.192 | 0.16 | 50 | 0.48 |

| model | Peak current | Torque constant | Back EMF | Motor length | Motor length | voltage range | Range of rotation | weight |

| Units | A | Nm/A | V/KRPM | g.cMoment of inertia | mm | VDC | RPM | Kg |

| 42BYA075B030C-02 | 9.6 | 0.05 | 3.947 | 14.6 | 134 | 24~48 | 1000~3000 | 1.0 |

Product Parameters

Quiet stable and reliable for long life operation

1.Voltage: 24 VDC

2.Number of phases: 3

3.Number of levels: 4

4.Line-to-line resistance: 1.45±10%ohms

5.Line-to-line inductance: 1.27±20%mH

6.Rated current: 3.2A

7.Rated power: 50W

8.No-load speed: 4300 rpm

9.Insulation class: B

10.Reduction ratio: 1:58.22

11.Output torque: 7.5 N.m

12.Output speed: 51.5 rpm

13.We can design the special voltage and shaft and so on

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Protection Type |

| Number of Poles: | 8 |

| Samples: |

US$ 162/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

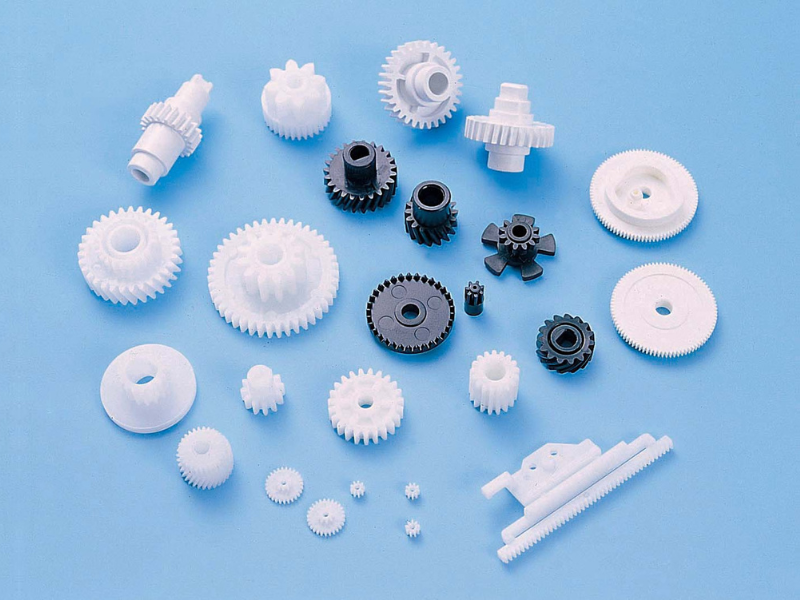

Can plastic wheels be customized for specific uses or environments?

Yes, plastic wheels can be customized for specific uses or environments to meet unique requirements and applications. Customization options for plastic wheels include:

- 1. Material Selection: Plastic wheels can be manufactured from various types of plastics, each with specific properties. Depending on the application, you can choose the most suitable plastic material to optimize factors like durability, chemical resistance, temperature tolerance, and load-bearing capacity.

- 2. Load Capacity: Custom plastic wheels can be designed with specific load-bearing capabilities in mind. Reinforcements and modifications to the wheel’s structure can be made to increase its load capacity, ensuring it can handle the intended weight.

- 3. Wheel Diameter: The size and diameter of the wheel can be customized to match the terrain and space constraints of the application. Whether you need smaller or larger wheels, customization is possible to ensure a perfect fit.

- 4. Tread Design: The tread pattern on plastic wheels can be tailored to provide optimal traction, stability, and noise reduction for specific environments. Different tread designs are available to suit various surfaces and conditions.

- 5. Bearings: Custom plastic wheels can be equipped with different types of bearings to meet performance requirements. Precision bearings, sealed bearings, or special bearing configurations can be chosen based on the application’s demands.

- 6. Environment-Specific Features: Plastic wheels can be customized with features like corrosion-resistant coatings, anti-static properties, UV resistance, and non-marking materials to accommodate specific environmental conditions.

- 7. Color and Aesthetics: Custom plastic wheels can be produced in various colors and finishes to match the aesthetics of the equipment or environment they are used in. This is common in applications like office furniture and consumer products.

- 8. Mounting Options: Custom wheels can be designed with specific mounting and attachment options to ensure a secure fit with the equipment or vehicle. Custom hubs or axle configurations can be provided.

- 9. Specialized Applications: For highly specialized applications, such as aerospace, healthcare, or automotive, plastic wheels can be customized to meet stringent industry standards and certifications.

- 10. Prototyping and Testing: Customization often involves prototyping and testing to ensure that the wheels meet the desired performance criteria. Manufacturers can work closely with customers to develop and refine custom wheel designs.

Customized plastic wheels are valuable for industries and applications with specific needs, ensuring that the wheels perform optimally and contribute to the overall functionality and efficiency of equipment or systems.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

Can you describe the factors to consider when selecting plastic wheels for specific applications?

Selecting the right plastic wheels for specific applications involves considering several crucial factors to ensure optimal performance and durability. Here are the key factors to keep in mind:

- 1. Load Capacity: Determine the weight that the wheels will need to support in your application. Choose wheels with a load capacity that comfortably exceeds the maximum expected load to prevent overloading and premature wear.

- 2. Wheel Diameter: The diameter of the wheel affects its stability, ease of rolling, and ability to overcome obstacles. Select a wheel diameter that suits the terrain and surface conditions in your application.

- 3. Tread Design: Consider the tread pattern on the wheel. Smooth treads offer lower rolling resistance, while treaded or ribbed designs provide better traction. Choose the tread type that aligns with your application’s requirements.

- 4. Material Selection: Plastic wheels are available in various materials, such as polyurethane, polypropylene, and nylon. The choice of material should consider factors like durability, impact resistance, chemical resistance, and temperature resistance based on your application’s environment.

- 5. Bearing Type: Determine the bearing type used in the wheels. Precision bearings, like ball bearings or roller bearings, reduce friction and ensure smooth rolling. Choose bearings appropriate for your application’s load and usage frequency.

- 6. Environment: Assess the operating environment. Consider factors such as exposure to moisture, chemicals, extreme temperatures, and potential corrosion. Select wheels that are suitable for the conditions they will encounter.

- 7. Floor Protection: If your application involves rolling on delicate flooring, consider wheels with softer materials or non-marking properties to protect the floor from damage or marking.

- 8. Mobility and Maneuverability: Evaluate the required mobility and maneuverability of your equipment or vehicle. Swivel casters may be needed for tight spaces, while fixed wheels offer stability in straight-line movement.

- 9. Noise Level: Consider the noise level generated by the wheels. Some applications, like office furniture, require quiet operation. Choose wheels designed to minimize noise if noise is a concern.

- 10. Maintenance: Assess the maintenance requirements of the wheels. Some wheels may require regular lubrication or cleaning, while others are low-maintenance. Ensure that the maintenance demands align with your operational capabilities.

- 11. Mounting and Attachment: Check the compatibility of the wheel’s mounting and attachment method with your equipment or vehicle. The design should securely attach to prevent wobbling or detachment.

- 12. Budget: Consider your budget constraints. Different types of plastic wheels come at various price points. Balance your budget with the need for quality and durability.

By carefully evaluating these factors and selecting plastic wheels that align with your specific application’s requirements, you can ensure that your equipment or vehicle operates optimally, efficiently, and safely.

editor by CX 2024-01-09

China manufacturer Nmrv Worm Gearbox with Motor with Best Sales

Merchandise Description

RV collection Traits

- RV – Measurements:030-040-050-063-075-one hundred and five-a hundred and ten-130-one hundred fifty

- Input Possibilities: with enter shaft, With Sq. flange,With Input Flange

- Enter Electricity .06 to 11 kW

- RV-Dimension from 030 to 105 in die-forged aluminium alloy budy and in excess of a hundred and ten in forged iron

- Ratios between 5 and a hundred

- Max torque 1550 N.m and admissible output radial masses max 8771 N

- Aluminium units are equipped complete with artificial oil and let for CZPT mounting positions, with no need to have to modify CZPT quantity

- Worm wheel: Copper (KK Cu).

- Loading potential in accordance with: ISO 9001:2015/GB/T 19001-2016

- Measurement 030 and more than are painted with RAL 5571 blue

- Worm gear reducers are offered with diffferent combos: NMRV+NMRV, NMRVpower+NMRV, JWB+NMRV

- NMRV, NRV+VS,NMRV+AS,NMRV+VS,NMRV+F

- Possibilities: torque arm, output flange, viton oil seals, low/large temperature oil, filling/drain/breather/level plug,Tiny hole

Basic types can be used to a broad variety of electrical power reduction ratios from 5 to a thousand.

Warranty: One year from day of delivery.

Starshine Drive

ZheJiang CZPT Co.,Ltd,the predecessor was a state-owned armed forces CZPT organization, was proven in 1965. CZPT specializes in the comprehensive electrical power transmission remedy for higher-conclude gear manufacturing industries dependent on the goal of “Platform Solution, Software Style and Expert Service”.

Starshine have a sturdy complex pressure with in excess of 350 employees at present, like above 30 engineering professionals, 30 good quality inspectors, masking an area of 80000 square meters and types of superior processing equipment and screening equipments. We have a good foundation for the industry software advancement and provider of substantial-finish pace reducers & variators owning to the provincial engineering technological innovation analysis heart,the lab of gear velocity reducers, and the foundation of CZPT R&D.

Our Staff

Top quality Management

Top quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

three. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection responsible for tracking bad, to monitor the supplier to take corrective measures

to prevent recurrence.

four. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the product

is a product inspection to determine the qualified products.

Packing

Supply

What Is a Worm Equipment Reducer?

If you have never ever noticed a worm equipment reducer just before, you might be missing out! Discover much more about these outstanding gears and their purposes by looking through this post! In addition to worm gear reducers, find out about worms and how they are produced. You’ll also discover what sorts of machines can benefit from worm gears, such as rock crushers and elevators. The adhering to details will assist you understand what a worm gear reducer is and how to uncover 1 in your location.

Standard worm shaft

A standard worm has two shafts, 1 for advancing and one for receding, which sort the axial pitch of the equipment. Typically, there are 8 normal axial pitches, which create a simple dimension for worm creation and inspection. The axial pitch of the worm equals the circular pitch of the gear in the central plane and the master lead cam’s radial pitch. A solitary set of alter gears and one master direct cam are utilized to make each dimension of worm.

Worm equipment is typically employed to manufacture a worm shaft. It is a dependable and productive gear reduction technique that does not shift when the electrical power is eliminated. Standard worm gears appear in normal sizes as properly as assisted methods. Companies can be identified on the web. Shown underneath are some typical supplies for worm gears. There are also a lot of alternatives for lubrication. The worm equipment is usually produced from situation hardened metal or bronze. Non-metallic components are also employed in light-weight-duty applications.

A self-locking worm gear stops the worm from transferring backwards. Standard worm gears are typically self-locking when the guide angle is less than eleven degrees. However, this feature can be harmful to systems that demand reverse sensitivity. If the direct angle is significantly less than 4 degrees, back-driving is unlikely. Nonetheless, if fall short-risk-free safety is a prerequisite, back again-driving worm gears must have a constructive brake to steer clear of reverse movement.

Worm gears are often utilized in transmission applications. They are a far more efficient way to reduce the pace of a device in contrast to standard equipment sets. Their lowered velocity is possible thanks to their low ratio and couple of parts. In contrast to conventional equipment sets, worm gears call for much less routine maintenance and decrease mechanical failure than a conventional gear set. Although they demand much less parts, worm gears are also far more resilient than traditional equipment sets.

There are two sorts of worm tooth types. Convex and involute helicoids have various types of teeth. The previous uses a straight line to intersect the involute worm creating line. The latter, on the other hand, uses a trapezoid dependent on the central cross part of the root. Both of these tooth types are utilized in the manufacturing of worms. And they have various variations in pitch diameter.

Types of worms

Worms have numerous kinds of tooth. For ease in production, a trapezoid-dependent tooth type is employed. Other forms include an involute helicoidal or a convolute worm creating a line. The following is a description of each and every type. All varieties are equivalent, and some might be chosen more than other people. Detailed beneath are the a few most common worm shaft kinds. Each and every type has its possess advantages and drawbacks.

Discrete compared to parallel axis: The design and style of a worm equipment establishes its ratio of torque. It really is a blend of two distinct metals – one particular for the worm and 1 for the wheel – which assists it take in shock hundreds. Building equipment and off-street autos usually need varying torques to maneuver above different terrain. A worm gear program can aid them maneuver over uneven terrain with no causing excessive wear.

Worm gear units have the greatest ratio. The sliding motion of the worm shaft final results in a substantial self-locking torque. Based on the angle of inclination and friction, a worm gear can achieve up to one hundred:1! Worm gears can be produced of various materials dependent on their inclination and friction angle. Worm gears are also helpful for equipment reduction programs, such as lubrication or grinding. Nevertheless, you ought to think about that heavier gears tend to be more difficult to reverse than lighter kinds.

Steel alloy: Stainless steel, brass, and aluminum bronze are typical supplies for worm gears. All a few sorts have unique advantages. A bronze worm equipment is generally composed of a blend of copper, zinc, and tin. A bronze shaft is more corrosive than a brass one, but it is a durable and corrosion-resistant selection. Metal alloys: These components are used for equally the worm wheel.

The effectiveness of worm gears depends on the assembly conditions and the lubricant. A 30:1 ratio reduces the effectiveness to 81:1%. A worm equipment is more efficient at larger ratios than an helical gear, but a thirty:1 ratio lowers the performance to eighty one%. A helical equipment minimizes speed while preserving torque to close to fifteen% of the unique velocity. The big difference in efficiency among worm equipment and helical equipment is about 50 percent an hour!

Techniques of producing worm shafts

A number of methods of manufacturing worm shafts are available in the market place. Single-pointed lathe resources or stop mills are the most well-known methods for manufacturing worms. These resources are able of producing worms with distinct pressure angles relying on their diameter, the depth of thread, and the grinding wheel’s diameter. The diagram under exhibits how various strain angles impact the profile of worms made using diverse slicing tools.

The technique for generating worm shafts requires the process of developing the suitable outer diameter of a typical worm shaft blank. This might contain contemplating the amount of reduction ratios in a loved ones, the distance among the worm shaft and the gear set heart, as well as the torques associated. These processes are also referred to as ‘thread assembly’. Every single process can be more refined if the sought after axial pitch can be achieved.

The axial pitch of a worm should match the round pitch of the greater gear. This is named the pitch. The pitch diameter and axial pitch need to be equivalent. Worms can be remaining-handed or proper-handed. The guide, which refers to the length a position on the thread travels for the duration of 1 revolution of the worm, is outlined by its angle of tangent to the helix on the pitch of the cylinder.

Worm shafts are frequently made making use of a worm equipment. Worm gears can be employed in distinct purposes due to the fact they offer good adjustment and high equipment reduction. They can be created in the two standard dimensions and assisted techniques. Worm shaft manufacturers can be discovered online. Alternatively, you can contact a maker straight to get your worm gears manufactured. The approach will consider only a couple of minutes. If you are searching for a manufacturer of worm gears, you can look through a directory.

Worm gears are manufactured with hardened metallic. The worm wheel and gear are yellow in color. A compounded oil with rust and oxidation inhibitors is also utilized to make worm gears. These oils adhere to the shaft walls and make a protecting barrier amongst the surfaces. If the compounded oil is utilized correctly, the worm gear will minimize the sounds in a motor, resulting in a smoother performance.

applications for worm gear reducers

Worm gears are broadly employed in electricity transmission applications, supplying a compact, large reduction, minimal-velocity push. To figure out the torque ratio of worm gears, a numerical model was produced that tends to make use of the equation of displacement compatibility and the influence coefficient approach, which supplies fast computing. The numerical product also incorporates bending deflections of the gear surfaces and the mating surfaces. It is primarily based on the Boussinesq concept, which calculates neighborhood contact deformations.

Worm gears can be developed to be appropriate or remaining-handed, and the worm can turn either clockwise or counter-clockwise. An internal helical equipment calls for the exact same hand to operate each elements. In contrast, an external helical equipment should be operated by the opposite hand. The same basic principle applies to worm gears in other applications. The torque and electricity transferred can be big, but worm gears are ready to cope with big reductions in the two directions.

Worm gears are really beneficial in industrial machinery patterns. They minimize sounds amounts, conserve room, and give machines further precision and fast-stopping abilities. Worm gears are also available in compact variations, producing them ideal for hoisting programs. This type of equipment reducer is utilised in industrial settings the place room is an situation. Its smaller sized measurement and significantly less sounds helps make it ideal for programs that require the device to quit swiftly.

A double-throated worm equipment offers the maximum load ability while still remaining compact. The double-throated variation features concave tooth on both worm and gear, doubling the speak to spot amongst them. Worm gears are also beneficial for lower to moderate-horsepower purposes, and their higher ratios, large output torque, and substantial speed reduction make them a desirable decision for a lot of applications. Worm gears are also quieter than other kinds of gears, lowering the noise and vibrations that they lead to.

Worm gears have quite a few advantages in excess of other kinds of gears. They have substantial levels of conformity and can be labeled as a screw pair in a reduce-pair equipment loved ones. Worm gears are also identified to have a high diploma of relative sliding. Worm gears are typically manufactured of hardened steel or phosphor-bronze, which offers great surface finish and rigid positioning. Worm gears are lubricated with particular lubricants that contain area-energetic additives. Worm gear lubrication is a blended lubrication approach and leads to delicate put on and tear.

China factory DC Motor Electric Engine 110V/220V/230VDC Dcr7832 with Worm Geared Box for Low Speed Blender near me supplier

Solution Description

Skilled Producer OF Solitary-Section Sequence MOTOR /Equipment MOTOR

Electrical power,Speed,Torque,Shaft ,Stator Lamination,Rotation And Installing Location

can be customized according to consumer‘s requirements.

Solution Description

Remarks:

- The performances as previously mentioned are just for reference only. We can modify our motor requirements according to customer’s demands.

- OEM & ODM are equally accessible. Please feel cost-free to get in touch with us with your detailed needs .

- If inquire for quotation, remember to tell voltage, draft, enter energy, air movement at least, so we could quotation speedily.

Element View:

Assembly Drawning:

Short Introduction

HangZhou Xihu (West Lake) Dis. HangZhoua Electric Equipment Factory was proven in 1997, it is found in Xihu (West Lake) Dis. District of HangZhou, ZHangZhoug Province.We have about fifty,000 sq. meters of the developing and virtually three hundred staff. In addition, the transportation around the manufacturing unit is very convenient, it is close to the TongSan Highway, and is just 8 kilometers away from the HangZhou Airport.

By way of many years of accumulation and development, our factory is now a skilled maker of one-stage series motor and equipment reducer motor.The application of our merchandise covers a lot of fields,it is mostly used in property kitchen area appliances or electric instruments, these kinds of as juicer, ice crusher, meat grinder, espresso bean grinder , garden mower and so on.

Our manufacturing facility has innovative CZPT motor production line, strong technical power, excellent testing signifies, merchandise can be produced in accordance to worldwide and domestic standards, but also in accordance to customer demands or offered samples, drawings and other special style.Our perform sticks to the theory of striving for existence by fantastic top quality. Our merchandise market much all more than the planet.Our factory will, and as always, wholeheartedly serves wide aged and new buyers both at property and abroad. We are seeking forward to developing company interactions with consumers all above the globe.

FAQ:

Q1: Are you a trade organization or a producer?

A1: HangZhou Xihu (West Lake) Dis. HangZhoua Motor Manufactory was recognized in 1997, we are a specialist

manufacturer of solitary-phase series motor and equipment motor.

Qtwo: How about sample and charge?

A2: Our sample policy stipulates that buyers need to pay out for sample and convey payment,but we could

return the sample and convey payment based mostly on particular get quantity. You can specify the specific business you want that like DHL, or you can phone your courier to select up from our manufacturing unit.

Q3: What is your payment phrases?

A3: 1. We take T/T, D/P, L/C at sight.

2. thirty% deposit in advance and 70% harmony before cargo.(Quantity much more than 3000USD)

Q4: How can we get comprehensive value?

A4: Please offer us in depth data of the merchandise,certain packaging requirements and purchasing

quantity.

Qfive: Is it feasible to visit your manufacturing facility

A5: Confident. But make sure you kindly maintain us posted a handful of days in progress. We need to verify our schedule to see if we are available then.

Q6: How to guarantee punctual cargo for my buy?

Asix: We give precedence to export orders and hold updating development from manufacturing to supply.

Qseven: What about the after-revenue services?

Aseven: Through email messages, photographs or guest samples to affirm the real lead to of the dilemma. If there is really

a product issue, we will redo with no cost.

Q8: What is your supply day?

A8: The shipping day is about twenty-30 days after acquiring your deposit,it is dependent on the amount you

order.

How to Establish the Quality of a Worm Shaft

There are numerous rewards of a worm shaft. It is less difficult to manufacture, as it does not demand guide straightening. Amongst these benefits are relieve of maintenance, lowered price, and relieve of installation. In addition, this variety of shaft is much less prone to hurt owing to guide straightening. This write-up will examine the different elements that figure out the top quality of a worm shaft. It also discusses the Dedendum, Root diameter, and Wear load ability.

Root diameter

There are a variety of possibilities when picking worm gearing. The variety depends on the transmission utilized and manufacturing choices. The standard profile parameters of worm gearing are described in the professional and agency literature and are used in geometry calculations. The picked variant is then transferred to the main calculation. However, you have to just take into account the power parameters and the gear ratios for the calculation to be exact. Right here are some tips to pick the correct worm gearing.

The root diameter of a worm equipment is calculated from the centre of its pitch. Its pitch diameter is a standardized worth that is established from its strain angle at the position of zero gearing correction. The worm gear pitch diameter is calculated by including the worm’s dimension to the nominal center length. When defining the worm gear pitch, you have to keep in head that the root diameter of the worm shaft have to be smaller than the pitch diameter.

Worm gearing demands teeth to evenly distribute the wear. For this, the tooth facet of the worm have to be convex in the normal and centre-line sections. The condition of the enamel, referred to as the evolvent profile, resembles a helical equipment. Typically, the root diameter of a worm equipment is more than a quarter inch. However, a 50 percent-inch difference is satisfactory.

One more way to calculate the gearing effectiveness of a worm shaft is by seeking at the worm’s sacrificial wheel. A sacrificial wheel is softer than the worm, so most wear and tear will occur on the wheel. Oil examination reports of worm gearing models practically usually show a higher copper and iron ratio, suggesting that the worm’s gearing is ineffective.

Dedendum

The dedendum of a worm shaft refers to the radial size of its tooth. The pitch diameter and the minor diameter figure out the dedendum. In an imperial technique, the pitch diameter is referred to as the diametral pitch. Other parameters contain the experience width and fillet radius. Encounter width describes the width of the equipment wheel with out hub projections. Fillet radius actions the radius on the suggestion of the cutter and types a trochoidal curve.

The diameter of a hub is measured at its outer diameter, and its projection is the distance the hub extends over and above the equipment confront. There are two kinds of addendum enamel, 1 with quick-addendum enamel and the other with lengthy-addendum tooth. The gears by themselves have a keyway (a groove machined into the shaft and bore). A crucial is equipped into the keyway, which matches into the shaft.

Worm gears transmit motion from two shafts that are not parallel, and have a line-toothed design and style. The pitch circle has two or a lot more arcs, and the worm and sprocket are supported by anti-friction roller bearings. Worm gears have high friction and use on the tooth tooth and restraining surfaces. If you would like to know more about worm gears, consider a look at the definitions beneath.

CZPT’s whirling procedure

Whirling approach is a present day production strategy that is changing thread milling and hobbing processes. It has been able to decrease manufacturing fees and lead instances whilst generating precision gear worms. In addition, it has reduced the need for thread grinding and surface roughness. It also reduces thread rolling. This is more on how CZPT whirling approach performs.

The whirling process on the worm shaft can be utilised for generating a selection of screw kinds and worms. They can produce screw shafts with outer diameters of up to 2.5 inches. In contrast to other whirling procedures, the worm shaft is sacrificial, and the procedure does not require machining. A vortex tube is utilized to produce chilled compressed air to the reducing level. If necessary, oil is also additional to the combine.

One more method for hardening a worm shaft is referred to as induction hardening. The procedure is a large-frequency electrical approach that induces eddy currents in metallic objects. The increased the frequency, the more surface heat it generates. With induction heating, you can system the heating method to harden only distinct locations of the worm shaft. The duration of the worm shaft is typically shortened.

Worm gears offer several rewards above common equipment sets. If employed correctly, they are trustworthy and highly productive. By subsequent correct setup guidelines and lubrication recommendations, worm gears can produce the identical dependable support as any other type of gear set. The write-up by Ray Thibault, a mechanical engineer at the College of Virginia, is an excellent information to lubrication on worm gears.

Wear load potential

The use load capability of a worm shaft is a crucial parameter when deciding the efficiency of a gearbox. Worms can be produced with distinct gear ratios, and the layout of the worm shaft must replicate this. To figure out the wear load capability of a worm, you can verify its geometry. Worms are usually manufactured with tooth ranging from one particular to 4 and up to twelve. Choosing the right number of teeth is dependent on many factors, which includes the optimisation specifications, this sort of as effectiveness, bodyweight, and centre-line distance.

Worm gear tooth forces increase with elevated energy density, leading to the worm shaft to deflect a lot more. This minimizes its use load ability, lowers performance, and boosts NVH actions. Advancements in lubricants and bronze resources, combined with far better production high quality, have enabled the constant increase in electrical power density. Individuals 3 aspects merged will determine the wear load capability of your worm equipment. It is crucial to contemplate all three elements prior to picking the appropriate gear tooth profile.

The bare minimum quantity of equipment tooth in a equipment is dependent on the strain angle at zero gearing correction. The worm diameter d1 is arbitrary and is dependent on a recognized module benefit, mx or mn. Worms and gears with various ratios can be interchanged. An involute helicoid makes certain correct make contact with and form, and provides larger accuracy and existence. The involute helicoid worm is also a crucial part of a equipment.

Worm gears are a form of historical equipment. A cylindrical worm engages with a toothed wheel to decrease rotational velocity. Worm gears are also utilised as primary movers. If you might be seeking for a gearbox, it could be a great option. If you are taking into consideration a worm gear, be confident to check its load capability and lubrication requirements.

NVH actions

The NVH conduct of a worm shaft is established utilizing the finite factor strategy. The simulation parameters are defined utilizing the finite component strategy and experimental worm shafts are in comparison to the simulation final results. The benefits display that a huge deviation exists amongst the simulated and experimental values. In addition, the bending stiffness of the worm shaft is hugely dependent on the geometry of the worm gear toothings. Therefore, an ample style for a worm gear toothing can aid lessen the NVH (sounds-vibration) actions of the worm shaft.

To compute the worm shaft’s NVH behavior, the major axes of instant of inertia are the diameter of the worm and the amount of threads. This will affect the angle among the worm enamel and the effective distance of every tooth. The distance in between the principal axes of the worm shaft and the worm gear is the analytical equivalent bending diameter. The diameter of the worm gear is referred to as its successful diameter.

The enhanced electricity density of a worm equipment results in elevated forces performing on the corresponding worm gear tooth. This sales opportunities to a corresponding increase in deflection of the worm equipment, which negatively impacts its efficiency and use load capacity. In addition, the rising energy density calls for enhanced producing high quality. The constant advancement in bronze components and lubricants has also facilitated the ongoing improve in electricity density.

The toothing of the worm gears decides the worm shaft deflection. The bending stiffness of the worm gear toothing is also calculated by using a tooth-dependent bending stiffness. The deflection is then transformed into a stiffness value by using the stiffness of the specific sections of the worm shaft. As demonstrated in figure 5, a transverse part of a two-threaded worm is shown in the figure.

China Hot selling Shaft Mounted Helical Worm Gear Motor Speed Reducer wholesaler

Merchandise Description

AOKMAN S Sequence Appropriate Angle Helical Worm Reduction Equipment Motor

1.Technical data

2.Input power rating and permissible torque

3.Gear unit weight

4.Buildings of S collection gearbox

five.Discipline Gear Box’s Usage

one. Metallurgy 2 Mine 3 Machine 4 Energy 5 Transportation 6 Water Conserbancy 7 Tomacco 8 Pharmacy 9 Printing Deal 10 Chemical industry…

six.Our providers:

seven.S sequence gearbox are offered in the following styles:

(1) SY

Foot mounted helical worm gearbox with solid shaft

(2) SAY

Helical worm gearbox with hollow shaft

(3) SAZY

Small flange mounted helical worm gearbox with hollow shaft

(4) SA (S,SF,SAF,SAZ)Y

Assemble users’ motor or unique motor, flange is necessary

(5) SFY

Flange mounted helical worm gearbox with strong shaft

(6) SAFY

Flange mounted helical worm gearbox with hollow shaft

(7) SATY

Torque arm mounted helical worm gearbox with hollow shaft

(8) S (SF,SA,SAF,SAZ) S

Shaft enter helical worm gearbox

(9) SA (S,SF,SAF,SAZ)RY

Mixed helical worm gearbox

(ten) SA (S,SF,SAF,SAZ)SR

Shaft input combined helical worm gearbox

Consumer going to:

11.FAQ:

one.Q:What kinds of gearbox can you make for us?

A:Major merchandise of our company: UDL series velocity variator,RV series worm gear reducer, ATA collection shaft mounted gearbox, X,B collection gear reducer,

P collection planetary gearbox and R, S, K, and F series helical-tooth reducer, more

than 1 hundred types and countless numbers of specifications

2.Q:Can you make as for every custom made drawing?

A: Sure, we offer customized provider for clients.

three.Q:What is your terms of payment ?

A: thirty% Progress payment by T/T soon after signing the agreement.70% just before delivery

4.Q:What is your MOQ?

A: 1 Set

If you are intrigued in our solution, welcome you make contact with me.

Our staff will assistance any need you may have.

An Overview of Worm Shafts and Gears

This post offers an overview of worm shafts and gears, such as the variety of toothing and deflection they knowledge. Other subject areas lined contain the use of aluminum vs . bronze worm shafts, calculating worm shaft deflection and lubrication. A comprehensive knowing of these troubles will support you to design better gearboxes and other worm gear mechanisms. For more data, make sure you pay a visit to the associated web sites. We also hope that you will locate this article informative.

Double throat worm gears

The pitch diameter of a worm and the pitch of its worm wheel need to be equal. The two sorts of worm gears have the exact same pitch diameter, but the distinction lies in their axial and round pitches. The pitch diameter is the distance amongst the worm’s teeth alongside its axis and the pitch diameter of the larger gear. Worms are produced with remaining-handed or appropriate-handed threads. The guide of the worm is the distance a position on the thread travels in the course of one revolution of the worm gear. The backlash measurement need to be manufactured in a handful of diverse areas on the gear wheel, as a massive sum of backlash indicates tooth spacing.

A double-throat worm gear is made for large-load purposes. It provides the tightest relationship in between worm and equipment. It is vital to mount a worm gear assembly accurately. The keyway design and style calls for numerous details of contact, which block shaft rotation and assist transfer torque to the equipment. Soon after deciding the area of the keyway, a hole is drilled into the hub, which is then screwed into the equipment.

The twin-threaded style of worm gears allows them to withstand heavy masses with no slipping or tearing out of the worm. A double-throat worm gear offers the tightest link among worm and equipment, and is therefore excellent for hoisting apps. The self-locking mother nature of the worm gear is one more edge. If the worm gears are created nicely, they are superb for lowering speeds, as they are self-locking.

When choosing a worm, the quantity of threads that a worm has is crucial. Thread commences decide the reduction ratio of a pair, so the greater the threads, the increased the ratio. The very same is true for the worm helix angles, which can be 1, two, or 3 threads prolonged. This differs in between a single thread and a double-throat worm equipment, and it is crucial to take into account the helix angle when selecting a worm.

Double-throat worm gears vary in their profile from the genuine equipment. Double-throat worm gears are especially beneficial in purposes in which sounds is an problem. In addition to their low sounds, worm gears can absorb shock loads. A double-throat worm gear is also a well-liked decision for a lot of different types of purposes. These gears are also typically utilized for hoisting products. Its tooth profile is various from that of the actual equipment.

Bronze or aluminum worm shafts

When picking a worm, a number of items should be kept in brain. The content of the shaft must be either bronze or aluminum. The worm by itself is the principal element, but there are also addendum gears that are available. The whole amount of enamel on equally the worm and the addendum gear ought to be better than forty. The axial pitch of the worm needs to match the circular pitch of the more substantial equipment.

The most common substance used for worm gears is bronze simply because of its desirable mechanical homes. Bronze is a broad phrase referring to different copper alloys, like copper-nickel and copper-aluminum. Bronze is most generally designed by alloying copper with tin and aluminum. In some circumstances, this combination generates brass, which is a related metal to bronze. The latter is much less costly and suited for light-weight masses.

There are a lot of advantages to bronze worm gears. They are sturdy and sturdy, and they supply excellent use-resistance. In distinction to steel worms, bronze worm gears are quieter than their counterparts. They also require no lubrication and are corrosion-resistant. Bronze worms are well-liked with modest, gentle-excess weight machines, as they are effortless to sustain. You can read through far more about worm gears in CZPT’s CZPT.

Though bronze or aluminum worm shafts are the most widespread, equally materials are similarly suitable for a range of apps. A bronze shaft is usually named bronze but may really be brass. Historically, worm gears had been created of SAE sixty five gear bronze. Nevertheless, more recent resources have been introduced. SAE 65 equipment bronze (UNS C90700) remains the preferred substance. For higher-volume programs, the substance savings can be considerable.

Both types of worms are in essence the exact same in measurement and form, but the guide on the left and correct tooth surfaces can fluctuate. This enables for exact adjustment of the backlash on a worm with no altering the heart distance among the worm equipment. The various measurements of worms also make them simpler to manufacture and sustain. But if you want an especially little worm for an industrial software, you must consider bronze or aluminum.

Calculation of worm shaft deflection

The centre-line distance of a worm equipment and the quantity of worm tooth perform a critical position in the deflection of the rotor. These parameters need to be entered into the tool in the very same units as the main calculation. The picked variant is then transferred to the main calculation. The deflection of the worm gear can be calculated from the angle at which the worm teeth shrink. The pursuing calculation is helpful for developing a worm gear.

Worm gears are widely used in industrial purposes owing to their substantial transmittable torques and massive equipment ratios. Their hard/gentle materials combination tends to make them ideally suited for a extensive range of programs. The worm shaft is typically made of situation-hardened metal, and the worm wheel is fabricated from a copper-tin-bronze alloy. In most cases, the wheel is the location of speak to with the gear. Worm gears also have a lower deflection, as high shaft deflection can influence the transmission accuracy and enhance use.

One more technique for deciding worm shaft deflection is to use the tooth-dependent bending stiffness of a worm gear’s toothing. By calculating the stiffness of the specific sections of a worm shaft, the stiffness of the whole worm can be established. The approximate tooth location is proven in determine 5.

An additional way to determine worm shaft deflection is by utilizing the FEM technique. The simulation tool employs an analytical product of the worm gear shaft to establish the deflection of the worm. It is based on a two-dimensional product, which is much more suitable for simulation. Then, you require to enter the worm gear’s pitch angle and the toothing to estimate the highest deflection.

Lubrication of worm shafts

In order to shield the gears, worm drives demand lubricants that supply outstanding anti-use protection, higher oxidation resistance, and low friction. Although mineral oil lubricants are extensively used, synthetic foundation oils have better functionality qualities and lower working temperatures. The Arrhenius Price Rule states that chemical reactions double every single ten degrees C. Synthetic lubricants are the greatest choice for these apps.

Synthetics and compounded mineral oils are the most common lubricants for worm gears. These oils are formulated with mineral basestock and 4 to 6 per cent synthetic fatty acid. Surface-lively additives give compounded gear oils excellent lubricity and stop sliding dress in. These oils are suited for large-velocity apps, including worm gears. Nonetheless, synthetic oil has the drawback of currently being incompatible with polycarbonate and some paints.

Synthetic lubricants are expensive, but they can improve worm gear effectiveness and running life. Artificial lubricants typically slide into two groups: PAO artificial oils and EP artificial oils. The latter has a increased viscosity index and can be used at a range of temperatures. Artificial lubricants typically incorporate anti-dress in additives and EP (anti-wear).

Worm gears are frequently mounted above or beneath the gearbox. The proper lubrication is crucial to guarantee the proper mounting and procedure. Oftentimes, insufficient lubrication can cause the device to fall short quicker than envisioned. Due to the fact of this, a technician might not make a link in between the absence of lube and the failure of the device. It is important to comply with the manufacturer’s suggestions and use high-high quality lubricant for your gearbox.

Worm drives reduce backlash by reducing the engage in amongst equipment enamel. Backlash can trigger damage if unbalanced forces are launched. Worm drives are light-weight and tough since they have small relocating elements. In addition, worm drives are minimal-sound and vibration. In addition, their sliding motion scrapes absent excess lubricant. The continuous sliding motion generates a large volume of heat, which is why superior lubrication is vital.

Oils with a large film toughness and outstanding adhesion are excellent for lubrication of worm gears. Some of these oils include sulfur, which can etch a bronze equipment. In purchase to avoid this, it is imperative to use a lubricant that has large film strength and prevents asperities from welding. The excellent lubricant for worm gears is 1 that gives superb film power and does not contain sulfur.

China wholesaler 12V 240W DC Worm Gear Reducer Motor on Electronic Fishing Reels Jigging Machines with Good quality

Merchandise Description

Item Description

We are 1 OEM Producer for a variety of dump truck equipment motor, trap machine motor,NMRV worm gear motor, agricultural seeder motor, DC wiper motor, electric powered mobility motor, electric transaxle motor and many others.

1. Motor type: Long lasting magnet DC

two. Rated velocity: 2200rpm-3500rpm

three. Security: IP44, IP55

four. Voltage: 12V, 24V

5.Equipment Ratio: 25:1, thirty:1, fifty:1, sixty:1

6.Output pace: 52rpm, 80rpm, 98rpm, 103rpm, 184rpm

seven. Output power: 130W, 180W, 240W, 320W on this DC motor type

eight. Gearbox: worm and wheel

9. Insulation: Course F

ten. Performance: sixty five%

Detailed Pictures

Packaging & Shipping and delivery

1. Internal packing: CZPT bag, air bubble bag, carton, according to buyer’s ask for.

2. Outer packing: wooden circumstance, double corrugated carton or including pallet.

3. Make sure you remember to depart the right get in touch with Deal with information for delivery.

Merchandise Parameters

Company Profile

Our Core variety of DC motors, electric powered transaxle motor, wheelchair motor and gearboxes are especially developed to be interchangeable and versatile, this will help us preserve reduce inventory levels although obtaining the customization necessary for so many programs. The core offer you has also enabled us to offer you outstanding pricing amounts for reduced quantities, often prototypes are very costly owing to absence of economies of scale we have tried out to support with this as a lot as feasible. HangZhou CZPT can offer bespoke models for greater portions and offer a Offer Chain services in which we operate closely with our consumers to identify the optimum shipping and delivery schedule in accordance with OEM manufacturing stages. If you are looking for DC motors, wiper motors, electric powered transaxle motor, wheelchair motor and gearboxes, you have occur to the correct spot, our skilled specialized sales employees will recommend the very best attainable selection for equally your software and your pocket. Contact us now to talk about your application.

HangZhou CZPT TRADE CO., LTD is responsible for exporting the above goods, and we also import some critical goods from oversea marketplaces.

Our organization has obtained the correct of import and export from the Govt department.

It is necessary to get your particular necessity when making contact with us,

(1) for example of motor, voltage, electrical power, pace, output torque, connecting type and dimensions of shaft, outside the house construction drawing or related photos etc.

(2) for example of electrical transaxle, verify its wheel foundation, energy, voltage, sector field, operating pace, wheel tyre’s diameter and width, loaded fat and many others, and then we will give the exact offers.

For that reason, hope to get your opinions quickly.

You should view our method methods as beneath

(1) method these output shafts

(2)procedure these spur gears and sprockets

(3) turning machining

(4) assembly planning

(5) assembly workshop

(6) inspection check before cargo

Our Advantages

Select US FOR:

1. We provide engineer recommendation to your specified style in manufacturing advancement and price preserving.

two. R&D and QC section concentrate on the merchandise to meet your rigid needs.

three. Diverse area treatments offered, plating, electricity coating, painting, anodized,polishing, electrophoresis, etc.

four. Various proportions according to buyer’s request.

5. Various packagings according to particular specifications.

6. Customized and tailored orders are welcome.

7. Very good good quality and Rapid motion.

8. Our items have been exported to America, Australia,German,Korea,Indian.

Private Coverage:

1) The appointed items are only for you.

2) Your informations&paperwork are private.

3) Your drawings&sketch are confidential.

Following Revenue Support

Our items can be repaired or changed the new components with free of charge price in 3 months.

FAQ

Question:

1.Q:How about CZPT price?

A: mainly count on : 1.Drawing, 2.material, 3.weight and quantity.

We require to know the composition of every parts to evaluate the mould remedy by:

1) –Full design and style drawing or genuine sample —– the very best way

–PDF drawing with full dimension for every parts

–Plainly photos for each and every parts with far more angle-views to present each characteristics.

2)The supplies and surface area therapies.

three)The amount of order.

two.Q:How to manage the item processing?

A: The processing report or photos will be despatched to the customer each and every 7 days/ each and every thirty day period for evaluation.

3.Q:Who will personal the mould?

A:Buyer, also the CZPT can be stored in our manufacturing unit for foreseeable future buy.

4.Q:How extended do you make your quotation?

A:Soon after getting detail informations we will quote in 1 to 3 times.

5.Q: Are the samples/prototype cost-free of charge?

A: charged,but it will be returned to buyer when an get confirmed and order quantity is over 5000 pcs.

Soon after your drawing verified and expenses carried out for the prototype, we will produce a sample

by CNC machining. And the first demo samples (1-3pcs) will be shipped to buyer

by the DHL /Fedex at buyer’s specific account or prepay the categorical fees.

MOQ? — 100units and take sample get.

How to Decide the Quality of a Worm Shaft

There are numerous benefits of a worm shaft. It is easier to manufacture, as it does not require manual straightening. Amongst these advantages are relieve of maintenance, lowered price, and simplicity of installation. In addition, this type of shaft is much much less prone to hurt thanks to handbook straightening. This article will talk about the various factors that figure out the high quality of a worm shaft. It also discusses the Dedendum, Root diameter, and Put on load capacity.

Root diameter

There are numerous possibilities when selecting worm gearing. The variety relies upon on the transmission utilized and production prospects. The simple profile parameters of worm gearing are described in the professional and company literature and are utilised in geometry calculations. The picked variant is then transferred to the main calculation. Nevertheless, you have to consider into account the energy parameters and the equipment ratios for the calculation to be correct. Here are some tips to pick the correct worm gearing.

The root diameter of a worm equipment is measured from the centre of its pitch. Its pitch diameter is a standardized value that is determined from its stress angle at the position of zero gearing correction. The worm equipment pitch diameter is calculated by including the worm’s dimension to the nominal heart length. When defining the worm equipment pitch, you have to hold in head that the root diameter of the worm shaft need to be smaller sized than the pitch diameter.

Worm gearing calls for teeth to evenly distribute the dress in. For this, the tooth aspect of the worm need to be convex in the typical and centre-line sections. The condition of the enamel, referred to as the evolvent profile, resembles a helical gear. Normally, the root diameter of a worm gear is much more than a quarter inch. Nonetheless, a 50 percent-inch difference is appropriate.

Yet another way to determine the gearing performance of a worm shaft is by hunting at the worm’s sacrificial wheel. A sacrificial wheel is softer than the worm, so most dress in and tear will arise on the wheel. Oil analysis reports of worm gearing models almost usually display a substantial copper and iron ratio, suggesting that the worm’s gearing is ineffective.

Dedendum

The dedendum of a worm shaft refers to the radial length of its tooth. The pitch diameter and the minimal diameter establish the dedendum. In an imperial system, the pitch diameter is referred to as the diametral pitch. Other parameters incorporate the confront width and fillet radius. Face width describes the width of the gear wheel without having hub projections. Fillet radius measures the radius on the tip of the cutter and forms a trochoidal curve.

The diameter of a hub is calculated at its outer diameter, and its projection is the length the hub extends past the equipment experience. There are two varieties of addendum enamel, 1 with limited-addendum tooth and the other with prolonged-addendum teeth. The gears them selves have a keyway (a groove machined into the shaft and bore). A key is fitted into the keyway, which matches into the shaft.

Worm gears transmit movement from two shafts that are not parallel, and have a line-toothed design and style. The pitch circle has two or much more arcs, and the worm and sprocket are supported by anti-friction roller bearings. Worm gears have substantial friction and wear on the tooth enamel and restraining surfaces. If you would like to know a lot more about worm gears, consider a look at the definitions underneath.

CZPT’s whirling approach

Whirling method is a modern day production approach that is replacing thread milling and hobbing procedures. It has been able to minimize producing charges and lead times whilst creating precision equipment worms. In addition, it has reduced the need to have for thread grinding and area roughness. It also reduces thread rolling. Here’s much more on how CZPT whirling approach works.

The whirling approach on the worm shaft can be utilized for producing a selection of screw varieties and worms. They can create screw shafts with outer diameters of up to 2.5 inches. In contrast to other whirling processes, the worm shaft is sacrificial, and the procedure does not require machining. A vortex tube is employed to produce chilled compressed air to the reducing position. If required, oil is also extra to the blend.

Another method for hardening a worm shaft is known as induction hardening. The process is a high-frequency electrical procedure that induces eddy currents in metallic objects. The increased the frequency, the more area heat it generates. With induction heating, you can software the heating method to harden only specific places of the worm shaft. The size of the worm shaft is typically shortened.

Worm gears supply several advantages in excess of common equipment sets. If employed correctly, they are trustworthy and very productive. By pursuing proper set up suggestions and lubrication guidelines, worm gears can produce the same dependable service as any other kind of gear established. The article by Ray Thibault, a mechanical engineer at the College of Virginia, is an exceptional guide to lubrication on worm gears.

Dress in load ability

The dress in load capability of a worm shaft is a essential parameter when determining the effectiveness of a gearbox. Worms can be manufactured with various gear ratios, and the design and style of the worm shaft ought to replicate this. To determine the put on load ability of a worm, you can check its geometry. Worms are usually produced with teeth ranging from one particular to 4 and up to twelve. Choosing the correct amount of tooth is dependent on several aspects, like the optimisation requirements, this sort of as effectiveness, bodyweight, and centre-line distance.

Worm equipment tooth forces boost with elevated electrical power density, causing the worm shaft to deflect much more. This decreases its wear load potential, lowers efficiency, and increases NVH behavior. Developments in lubricants and bronze resources, combined with much better production high quality, have enabled the continuous boost in energy density. Those a few aspects merged will figure out the put on load capability of your worm equipment. It is essential to take into account all three factors prior to choosing the correct gear tooth profile.

The minimal number of equipment tooth in a equipment depends on the stress angle at zero gearing correction. The worm diameter d1 is arbitrary and depends on a identified module benefit, mx or mn. Worms and gears with distinct ratios can be interchanged. An involute helicoid makes certain proper contact and shape, and offers higher accuracy and life. The involute helicoid worm is also a important element of a gear.

Worm gears are a form of ancient gear. A cylindrical worm engages with a toothed wheel to reduce rotational pace. Worm gears are also utilised as primary movers. If you’re hunting for a gearbox, it might be a great option. If you might be contemplating a worm equipment, be positive to check out its load ability and lubrication demands.

NVH habits

The NVH habits of a worm shaft is determined using the finite aspect approach. The simulation parameters are described utilizing the finite factor technique and experimental worm shafts are when compared to the simulation final results. The final results present that a big deviation exists between the simulated and experimental values. In addition, the bending stiffness of the worm shaft is extremely dependent on the geometry of the worm gear toothings. Hence, an ample design and style for a worm equipment toothing can help reduce the NVH (sounds-vibration) habits of the worm shaft.

To compute the worm shaft’s NVH conduct, the principal axes of second of inertia are the diameter of the worm and the variety of threads. This will influence the angle between the worm enamel and the successful distance of every tooth. The distance amongst the main axes of the worm shaft and the worm gear is the analytical equal bending diameter. The diameter of the worm gear is referred to as its successful diameter.

The improved energy density of a worm gear final results in improved forces performing on the corresponding worm equipment tooth. This sales opportunities to a corresponding enhance in deflection of the worm gear, which negatively has an effect on its effectiveness and put on load ability. In addition, the escalating power density needs enhanced manufacturing top quality. The constant improvement in bronze supplies and lubricants has also facilitated the ongoing increase in energy density.

The toothing of the worm gears decides the worm shaft deflection. The bending stiffness of the worm equipment toothing is also calculated by making use of a tooth-dependent bending stiffness. The deflection is then transformed into a stiffness value by utilizing the stiffness of the person sections of the worm shaft. As demonstrated in determine 5, a transverse part of a two-threaded worm is demonstrated in the determine.

China Standard Competitive Price Cast Iron Housing Worm Gear Single Double Speed Gear Reducer Reduction for Electric Motor with Great quality

Solution Description

Merchandise Description

Firm Profile

In 2571, HangZhou CZPT Equipment Co.,ltd was established by Ms. Iris and her 2 associates(Mr. Tian and Mr. Yang) in HangZhou metropolis(ZHangZhoug province, China), all 3 Founders are engineers who have a lot more than averaged 30 a long time of expertise. Then simply because the requirements of organization growth, in 2014, it moved to the existing Xihu (West Lake) Dis. Industrial Zone (HangZhou city, ZHangZhoug province, China).

Via our well-identified model ND, CZPT Equipment provides agricultural solutions to agriculture equipment producer and distributors worldwide by way of a total line of spiral bevel gearboxes, straight bevel gearboxes, spur gearboxes, generate shafts, sheet steel, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators etc. Products can be customized as request.

We, CZPT machinery set up a comprehensive quality administration method and income services network to offer clientele with large-quality goods and satisfactory provider. Our items are offered in forty provinces and municipalities in China and 36 countries and locations in the world, our main industry is the European industry.

Our factory

Our sample room

Certifications

Why pick us?

1) Customization: With a sturdy R&D staff, and we can build merchandise as necessary. It only normally takes up to 7 times for us to design and style a set of drawings. The generation time for new products is typically 50 times or much less.

two) Top quality: We have our possess full inspection and tests tools, which can make sure the good quality of the merchandise.

three) Potential: Our yearly generation capacity is above five hundred,000 sets, also, we also take tiny quantity orders, to meet up with the needs of different customer’s purchase quantities.

four) Support: We target on giving large-high quality goods. Our goods are in line with worldwide requirements and are largely exported to Europe, Australia, and other nations around the world and areas.

five) Shipment: We are near to HangZhou and ZheJiang ports, to provide the quickest shipping and delivery provider.

Packaging & Transport

FAQ

Q: Are you a investing company or manufacturer?

A: We are factory and supplying gearbox ODM & OEM providers for the European industry for more than ten a long time

Q: Do you give samples? is it free of charge or additional?

A: Indeed, we could offer the sample for totally free cost but do not pay the price of freight.

Q: How prolonged is your shipping time? What is your conditions of payment?

A: Generally it is forty-forty five days. The time may possibly range based on the item and the level of customization.

For standard products, the payment is: 30% T/T in progress,stability prior to cargo.

Q: What is the actual MOQ or cost for your item?

A: As an OEM business, we can supply and adapt our goods to a wide variety of requirements.

As a result, MOQ and price tag might significantly fluctuate with measurement, materials and even more specifications For occasion, high priced goods or regular merchandise will normally have a decrease MOQ. Make sure you get in touch with us with all appropriate details to get the most precise quotation.

If you have yet another issue, make sure you feel totally free to contact us.

How to Choose the Correct Worm Shaft

You might be curious to know how to select the proper Worm Shaft. In this post, you will learn about worm modules with the identical pitch diameter, Double-thread worm gears, and Self-locking worm drive. After you have chosen the proper Worm Shaft, you will uncover it less difficult to use the gear in your residence. There are a lot of rewards to selecting the correct Worm Shaft. Study on to learn a lot more.

Concave form

The concave shape of a worm’s shaft is an important attribute for the design and style of a worm gearing. Worm gearings can be located in a vast selection of styles, and the simple profile parameters are accessible in specialist and organization literature. These parameters are employed in geometry calculations, and a selection of the proper worm gearing for a particular software can be based on these needs.

The thread profile of a worm is outlined by the tangent to the axis of its principal cylinder. The tooth are shaped in a straight line with a slightly concave condition together the sides. It resembles a helical equipment, and the profile of the worm alone is straight. This type of gearing is often employed when the number of teeth is better than a specific limit.

The geometry of a worm equipment relies upon on the kind and producer. In the earliest times, worms have been manufactured comparable to basic screw threads, and could be chased on a lathe. For the duration of this time, the worm was often produced with straight-sided equipment to make threads in the acme airplane. Later, grinding strategies improved the thread finish and reduced distortions ensuing from hardening.

When a worm gearing has several enamel, the pitch angle is a crucial parameter. A better pitch angle raises effectiveness. If you want to enhance the pitch angle without having growing the amount of enamel, you can substitute a worm pair with a different number of thread starts. The helix angle should increase whilst the centre length remains consistent. A higher pitch angle, nonetheless, is virtually in no way employed for energy transmissions.

The least quantity of equipment tooth is dependent on the angle of stress at zero gearing correction. The diameter of the worm is d1, and is dependent on a known module value, mx or mn. Typically, more substantial values of m are assigned to bigger modules. And a smaller sized amount of teeth is named a minimal pitch angle. In situation of a reduced pitch angle, spiral gearing is employed. The pitch angle of the worm equipment is more compact than 10 levels.

Multiple-thread worms

Multi-thread worms can be divided into sets of one, two, or 4 threads. The ratio is determined by the amount of threads on every single set and the amount of tooth on the apparatus. The most widespread worm thread counts are 1,2,4, and 6. To find out how numerous threads you have, depend the commence and stop of each and every thread and divide by two. Making use of this technique, you will get the proper thread count every single time.

The tangent airplane of a worm’s pitch profile adjustments as the worm moves lengthwise together the thread. The guide angle is finest at the throat, and decreases on equally sides. The curvature radius r” varies proportionally with the worm’s radius, or pitch angle at the regarded point. Consequently, the worm sales opportunities angle, r, is increased with lowered inclination and decreases with escalating inclination.

Multi-thread worms are characterised by a constant leverage between the equipment area and the worm threads. The ratio of worm-tooth surfaces to the worm’s duration differs, which allows the wormgear to be adjusted in the same route. To improve the equipment make contact with among the worm and equipment, the tangent relationship between the two surfaces is ideal.

The effectiveness of worm equipment drives is mostly dependent on the helix angle of the worm. Multiple thread worms can boost the efficiency of the worm equipment drive by as a lot as 25 to 50% when compared to one-thread worms. Worm gears are manufactured of bronze, which decreases friction and heat on the worm’s enamel. A specialized machine can minimize the worm gears for greatest performance.

Double-thread worm gears

In several diverse programs, worm gears are used to push a worm wheel. These gears are special in that the worm are not able to be reversed by the power used to the worm wheel. Due to the fact of their self-locking homes, they can be employed to avert reversing movement, although this is not a trusted perform. Applications for worm gears consist of hoisting gear, elevators, chain blocks, fishing reels, and automotive energy steering. Due to the fact of their compact size, these gears are typically utilised in programs with constrained space.

Worm sets typically show much more put on than other varieties of gears, and this implies that they demand more constrained get in touch with patterns in new areas. Worm wheel enamel are concave, making it tough to evaluate tooth thickness with pins, balls, and equipment tooth calipers. To evaluate tooth thickness, nevertheless, you can measure backlash, a measurement of the spacing amongst teeth in a equipment. Backlash can vary from one particular worm gear to yet another, so it is important to check the backlash at a number of factors. If the backlash is diverse in two spots, this implies that the teeth might have distinct spacing.

Solitary-thread worm gears provide higher pace reduction but lower efficiency. A multi-thread worm gear can offer high efficiency and high pace, but this arrives with a trade-off in terms of horsepower. Even so, there are many other apps for worm gears. In addition to weighty-obligation purposes, they are usually employed in light-obligation gearboxes for a selection of functions. When used in conjunction with double-thread worms, they allow for a considerable speed reduction in one particular action.

Stainless-metal worm gears can be employed in moist environments. The worm equipment is not prone to rust and is best for damp and moist environments. The worm wheel’s smooth surfaces make cleansing them easy. Even so, they do need lubricants. The most common lubricant for worm gears is mineral oil. This lubricant is designed to protect the worm generate.

Self-locking worm generate

A self-locking worm drive stops the platform from transferring backward when the motor stops. A dynamic self-locking worm generate is also attainable but does not include a holding brake. This sort of self-locking worm drive is not inclined to vibrations, but may rattle if introduced. In addition, it could need an additional brake to preserve the platform from transferring. A constructive brake might be required for security.

A self-locking worm travel does not let for the interchangeability of the pushed and driving gears. This is not like spur equipment trains that allow each to interchange positions. In a self-locking worm generate, the driving gear is often engaged and the driven gear remains stationary. The travel mechanism locks automatically when the worm is operated in the improper way. A number of sources of info on self-locking worm gears include the Machinery’s Handbook.

A self-locking worm push is not hard to develop and has a fantastic mechanical edge. In reality, the output of a self-locking worm push can not be backdriven by the enter shaft. DIYers can construct a self-locking worm generate by modifying threaded rods and off-the-shelf gears. Nonetheless, it is less complicated to make a ratchet and pawl system, and is drastically considerably less high-priced. Even so, it is critical to recognize that you can only push one worm at a time.

Another edge of a self-locking worm travel is the reality that it is not attainable to interchange the enter and output shafts. This is a key advantage of employing these kinds of a system, as you can attain large equipment reduction without having increasing the dimensions of the gear box. If you happen to be thinking about getting a self-locking worm equipment for a distinct application, consider the pursuing tips to make the proper choice.

An enveloping worm gear established is greatest for purposes demanding substantial precision and performance, and bare minimum backlash. Its enamel are formed differently, and the worm’s threads are modified to enhance floor contact. They are far more high-priced to manufacture than their solitary-start off counterparts, but this kind is greatest for apps where precision is vital. The worm drive is also a fantastic choice for heavy vehicles simply because of their big dimension and substantial-torque potential.

China Standard 90zyj PMDC 12V 24V 300W 500W Worm Geared DC Motor with high quality

Product Description

90ZYJ PMDC 12v 24v 300w 500w worm geared dc motor

one. Attributes of 90ZYJ

Voltage: 12v,24v

Velocity: 60-200rpm

Torque: 22-28N.m

Motor size: 155mm, 200mm

Standard applications: caravan, lifting device, working equipment, sliding doorway, and so on.

2. Technical specs of 90ZYJ

Be aware: It’s the common specification for reference only, we can pick DC motor with different voltage pace to fulfill your torque and pace prerequisite.

Business Profile

one. About us

Business Variety: Maker, Investing Firm Confirmed

Spot: ZHangZhoug, China (Mainland) Confirmed

Main Merchandise: dc motor,ac motor, gear motor, stepper motor, brushless motor

Total Employees: 51 – a hundred Men and women

Whole Yearly Revenue: $5 Million – $10 Million