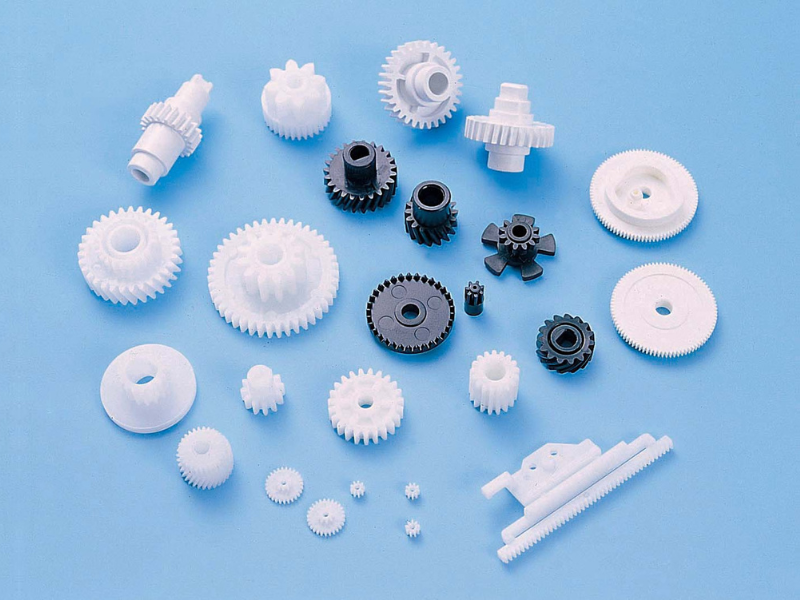

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Our Machine

Product Range

Contact Us /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Plastic |

| Customization: |

Available

|

|

|---|

Can plastic wheels be customized for specific uses or environments?

Yes, plastic wheels can be customized for specific uses or environments to meet unique requirements and applications. Customization options for plastic wheels include:

- 1. Material Selection: Plastic wheels can be manufactured from various types of plastics, each with specific properties. Depending on the application, you can choose the most suitable plastic material to optimize factors like durability, chemical resistance, temperature tolerance, and load-bearing capacity.

- 2. Load Capacity: Custom plastic wheels can be designed with specific load-bearing capabilities in mind. Reinforcements and modifications to the wheel’s structure can be made to increase its load capacity, ensuring it can handle the intended weight.

- 3. Wheel Diameter: The size and diameter of the wheel can be customized to match the terrain and space constraints of the application. Whether you need smaller or larger wheels, customization is possible to ensure a perfect fit.

- 4. Tread Design: The tread pattern on plastic wheels can be tailored to provide optimal traction, stability, and noise reduction for specific environments. Different tread designs are available to suit various surfaces and conditions.

- 5. Bearings: Custom plastic wheels can be equipped with different types of bearings to meet performance requirements. Precision bearings, sealed bearings, or special bearing configurations can be chosen based on the application’s demands.

- 6. Environment-Specific Features: Plastic wheels can be customized with features like corrosion-resistant coatings, anti-static properties, UV resistance, and non-marking materials to accommodate specific environmental conditions.

- 7. Color and Aesthetics: Custom plastic wheels can be produced in various colors and finishes to match the aesthetics of the equipment or environment they are used in. This is common in applications like office furniture and consumer products.

- 8. Mounting Options: Custom wheels can be designed with specific mounting and attachment options to ensure a secure fit with the equipment or vehicle. Custom hubs or axle configurations can be provided.

- 9. Specialized Applications: For highly specialized applications, such as aerospace, healthcare, or automotive, plastic wheels can be customized to meet stringent industry standards and certifications.

- 10. Prototyping and Testing: Customization often involves prototyping and testing to ensure that the wheels meet the desired performance criteria. Manufacturers can work closely with customers to develop and refine custom wheel designs.

Customized plastic wheels are valuable for industries and applications with specific needs, ensuring that the wheels perform optimally and contribute to the overall functionality and efficiency of equipment or systems.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

How does the design of a plastic wheel contribute to its durability and performance?

The design of a plastic wheel plays a significant role in determining its durability and performance. Several key design factors contribute to these attributes:

- 1. Material Selection: The choice of plastic material is crucial. High-quality plastics, such as polyurethane, polypropylene, and nylon, are commonly used for wheel construction. These materials offer excellent durability, impact resistance, and resistance to wear and tear.

- 2. Load Capacity: The design of the wheel must consider the expected load capacity. Reinforcements, such as ribbing or internal structures, can be added to strengthen the wheel and enhance its load-bearing capabilities. Proper load capacity design ensures that the wheel can support the intended weight without deformation or failure.

- 3. Bearing Type: The design of the wheel includes the type of bearing used. Precision bearings, such as ball bearings or roller bearings, reduce friction and ensure smooth rolling. Properly designed bearings enhance the wheel’s performance by reducing resistance and minimizing wear.

- 4. Tread Design: The tread design on the wheel affects its grip, stability, and noise level. Different tread patterns are used for specific applications. For example, smooth treads provide reduced rolling resistance, while treaded designs offer improved traction. The choice of tread design depends on the intended use.

- 5. Hub and Axle Compatibility: The design of the wheel’s hub and axle connection is essential for secure attachment. It should be compatible with the mounting hardware used in the application. A well-designed hub and axle connection ensure stability and prevent wobbling or detachment during use.

- 6. Resilience: The design should consider the wheel’s ability to absorb shocks and impacts. Resilient plastic materials can withstand sudden impacts without cracking or breaking. This is especially important in applications where the wheel may encounter rough terrain or obstacles.

- 7. Temperature Resistance: Depending on the application, plastic wheels may need to withstand a wide range of temperatures. The design should factor in the material’s temperature resistance to ensure that the wheel remains functional in extreme conditions.

- 8. Size and Dimensions: The size and dimensions of the wheel are critical for load distribution and stability. Properly sizing the wheel according to the application’s requirements ensures optimal performance and durability.

- 9. Corrosion Resistance: In some environments, corrosion resistance is essential. The design may incorporate materials or coatings that protect against corrosion, ensuring a longer service life.

- 10. Wheel Mounting: The method of mounting the wheel to the equipment or vehicle is part of the design. It should be secure and reliable to prevent wobbling or detachment during use.

- 11. Weight Distribution: Proper weight distribution across the wheel is important for even wear and reduced stress on the wheel. Design considerations may include the wheel’s shape and load-bearing capacity to ensure even weight distribution.

A well-designed plastic wheel takes into account these factors to maximize its durability and performance. It should be capable of withstanding the demands of its intended application while providing smooth and reliable movement.

editor by Dream 2024-05-08

China Professional Planar Double Enveloping Worm Gear Reducer Unit with Hollow Shaft near me shop

Solution Description

Planar Double Enveloping Worm Gear Reducer Device With Hollow Shaft

Operating situations

Two shafts for 90 ° Intersect, input velocity have to not be far more than 1500 rpm.The working environment temperature should range from 0 ~ 40 ° C, when the environment temperature below ° C or earlier mentioned 40 ° C.Before starting up the lubricating oil to corresponding heating and cooling, The worm shafts, reverse operation can be optimistic.

Knowledge sheet on CUW double enveloping worm gear reducer :

How to Figure out the High quality of a Worm Shaft

There are many rewards of a worm shaft. It is less difficult to manufacture, as it does not demand guide straightening. Between these rewards are simplicity of maintenance, diminished cost, and simplicity of set up. In addition, this sort of shaft is a lot significantly less inclined to hurt because of to guide straightening. This write-up will talk about the various variables that establish the good quality of a worm shaft. It also discusses the Dedendum, Root diameter, and Dress in load ability.

Root diameter

There are numerous possibilities when deciding on worm gearing. The selection depends on the transmission utilized and creation possibilities. The simple profile parameters of worm gearing are described in the professional and firm literature and are used in geometry calculations. The chosen variant is then transferred to the primary calculation. Even so, you need to get into account the energy parameters and the equipment ratios for the calculation to be exact. Below are some tips to select the appropriate worm gearing.

The root diameter of a worm gear is calculated from the heart of its pitch. Its pitch diameter is a standardized value that is decided from its strain angle at the point of zero gearing correction. The worm equipment pitch diameter is calculated by including the worm’s dimension to the nominal centre length. When defining the worm equipment pitch, you have to hold in thoughts that the root diameter of the worm shaft have to be scaled-down than the pitch diameter.

Worm gearing needs tooth to evenly distribute the put on. For this, the tooth facet of the worm have to be convex in the regular and centre-line sections. The form of the teeth, referred to as the evolvent profile, resembles a helical gear. Normally, the root diameter of a worm equipment is much more than a quarter inch. However, a 50 percent-inch difference is satisfactory.

An additional way to calculate the gearing effectiveness of a worm shaft is by looking at the worm’s sacrificial wheel. A sacrificial wheel is softer than the worm, so most dress in and tear will occur on the wheel. Oil evaluation reports of worm gearing models almost usually present a high copper and iron ratio, suggesting that the worm’s gearing is ineffective.

Dedendum

The dedendum of a worm shaft refers to the radial length of its tooth. The pitch diameter and the slight diameter figure out the dedendum. In an imperial method, the pitch diameter is referred to as the diametral pitch. Other parameters consist of the face width and fillet radius. Experience width describes the width of the gear wheel with no hub projections. Fillet radius actions the radius on the suggestion of the cutter and varieties a trochoidal curve.

The diameter of a hub is calculated at its outer diameter, and its projection is the distance the hub extends past the equipment confront. There are two varieties of addendum enamel, 1 with quick-addendum tooth and the other with lengthy-addendum enamel. The gears on their own have a keyway (a groove machined into the shaft and bore). A key is fitted into the keyway, which fits into the shaft.

Worm gears transmit movement from two shafts that are not parallel, and have a line-toothed layout. The pitch circle has two or more arcs, and the worm and sprocket are supported by anti-friction roller bearings. Worm gears have large friction and dress in on the tooth tooth and restraining surfaces. If you would like to know much more about worm gears, take a seem at the definitions below.

CZPT’s whirling procedure

Whirling method is a contemporary production method that is replacing thread milling and hobbing processes. It has been capable to reduce producing expenses and guide instances even though producing precision gear worms. In addition, it has diminished the want for thread grinding and surface roughness. It also lowers thread rolling. This is much more on how CZPT whirling process works.

The whirling method on the worm shaft can be utilized for making a assortment of screw types and worms. They can produce screw shafts with outer diameters of up to 2.5 inches. In contrast to other whirling procedures, the worm shaft is sacrificial, and the process does not require machining. A vortex tube is utilized to supply chilled compressed air to the cutting stage. If required, oil is also added to the mix.

Another method for hardening a worm shaft is named induction hardening. The method is a large-frequency electrical approach that induces eddy currents in metallic objects. The greater the frequency, the more floor warmth it generates. With induction heating, you can plan the heating process to harden only specific places of the worm shaft. The length of the worm shaft is normally shortened.

Worm gears offer quite a few advantages in excess of standard gear sets. If utilised accurately, they are trustworthy and highly efficient. By adhering to correct setup guidelines and lubrication guidelines, worm gears can provide the same reliable services as any other variety of gear established. The post by Ray Thibault, a mechanical engineer at the University of Virginia, is an superb guidebook to lubrication on worm gears.

Put on load potential

The use load capacity of a worm shaft is a crucial parameter when determining the efficiency of a gearbox. Worms can be created with various gear ratios, and the design of the worm shaft should reflect this. To figure out the use load ability of a worm, you can examine its geometry. Worms are usually created with teeth ranging from a single to four and up to twelve. Selecting the right number of enamel relies upon on numerous factors, including the optimisation demands, such as efficiency, excess weight, and centre-line length.

Worm equipment tooth forces boost with increased electricity density, causing the worm shaft to deflect a lot more. This lowers its wear load potential, lowers effectiveness, and will increase NVH habits. Advancements in lubricants and bronze materials, blended with greater production high quality, have enabled the ongoing increase in power density. Individuals 3 factors mixed will determine the put on load ability of your worm gear. It is vital to think about all 3 variables just before choosing the correct equipment tooth profile.

The minimal amount of equipment enamel in a gear depends on the force angle at zero gearing correction. The worm diameter d1 is arbitrary and depends on a identified module benefit, mx or mn. Worms and gears with diverse ratios can be interchanged. An involute helicoid makes certain appropriate make contact with and form, and gives greater precision and daily life. The involute helicoid worm is also a crucial element of a gear.

Worm gears are a type of ancient gear. A cylindrical worm engages with a toothed wheel to minimize rotational speed. Worm gears are also utilized as primary movers. If you are seeking for a gearbox, it could be a very good option. If you might be taking into consideration a worm equipment, be certain to examine its load potential and lubrication needs.

NVH actions

The NVH actions of a worm shaft is decided making use of the finite aspect method. The simulation parameters are defined employing the finite component strategy and experimental worm shafts are when compared to the simulation outcomes. The final results present that a big deviation exists in between the simulated and experimental values. In addition, the bending stiffness of the worm shaft is hugely dependent on the geometry of the worm gear toothings. Consequently, an sufficient layout for a worm equipment toothing can assist minimize the NVH (sound-vibration) actions of the worm shaft.

To determine the worm shaft’s NVH behavior, the main axes of second of inertia are the diameter of the worm and the variety of threads. This will impact the angle amongst the worm teeth and the effective distance of every single tooth. The distance among the main axes of the worm shaft and the worm equipment is the analytical equivalent bending diameter. The diameter of the worm gear is referred to as its efficient diameter.

The increased electricity density of a worm gear final results in elevated forces performing on the corresponding worm gear tooth. This leads to a corresponding boost in deflection of the worm equipment, which negatively affects its efficiency and put on load potential. In addition, the rising electrical power density requires improved producing top quality. The ongoing progression in bronze components and lubricants has also facilitated the ongoing improve in electricity density.

The toothing of the worm gears decides the worm shaft deflection. The bending stiffness of the worm equipment toothing is also calculated by employing a tooth-dependent bending stiffness. The deflection is then converted into a stiffness benefit by employing the stiffness of the specific sections of the worm shaft. As proven in figure 5, a transverse part of a two-threaded worm is proven in the figure.

China Hot selling Shaft Mounted Helical Worm Gear Motor Speed Reducer wholesaler

Merchandise Description

AOKMAN S Sequence Appropriate Angle Helical Worm Reduction Equipment Motor

1.Technical data

2.Input power rating and permissible torque

3.Gear unit weight

4.Buildings of S collection gearbox

five.Discipline Gear Box’s Usage

one. Metallurgy 2 Mine 3 Machine 4 Energy 5 Transportation 6 Water Conserbancy 7 Tomacco 8 Pharmacy 9 Printing Deal 10 Chemical industry…

six.Our providers:

seven.S sequence gearbox are offered in the following styles:

(1) SY

Foot mounted helical worm gearbox with solid shaft

(2) SAY

Helical worm gearbox with hollow shaft

(3) SAZY

Small flange mounted helical worm gearbox with hollow shaft

(4) SA (S,SF,SAF,SAZ)Y

Assemble users’ motor or unique motor, flange is necessary

(5) SFY

Flange mounted helical worm gearbox with strong shaft

(6) SAFY

Flange mounted helical worm gearbox with hollow shaft

(7) SATY

Torque arm mounted helical worm gearbox with hollow shaft

(8) S (SF,SA,SAF,SAZ) S

Shaft enter helical worm gearbox

(9) SA (S,SF,SAF,SAZ)RY

Mixed helical worm gearbox

(ten) SA (S,SF,SAF,SAZ)SR

Shaft input combined helical worm gearbox

Consumer going to:

11.FAQ:

one.Q:What kinds of gearbox can you make for us?

A:Major merchandise of our company: UDL series velocity variator,RV series worm gear reducer, ATA collection shaft mounted gearbox, X,B collection gear reducer,

P collection planetary gearbox and R, S, K, and F series helical-tooth reducer, more

than 1 hundred types and countless numbers of specifications

2.Q:Can you make as for every custom made drawing?

A: Sure, we offer customized provider for clients.

three.Q:What is your terms of payment ?

A: thirty% Progress payment by T/T soon after signing the agreement.70% just before delivery

4.Q:What is your MOQ?

A: 1 Set

If you are intrigued in our solution, welcome you make contact with me.

Our staff will assistance any need you may have.

An Overview of Worm Shafts and Gears

This post offers an overview of worm shafts and gears, such as the variety of toothing and deflection they knowledge. Other subject areas lined contain the use of aluminum vs . bronze worm shafts, calculating worm shaft deflection and lubrication. A comprehensive knowing of these troubles will support you to design better gearboxes and other worm gear mechanisms. For more data, make sure you pay a visit to the associated web sites. We also hope that you will locate this article informative.

Double throat worm gears

The pitch diameter of a worm and the pitch of its worm wheel need to be equal. The two sorts of worm gears have the exact same pitch diameter, but the distinction lies in their axial and round pitches. The pitch diameter is the distance amongst the worm’s teeth alongside its axis and the pitch diameter of the larger gear. Worms are produced with remaining-handed or appropriate-handed threads. The guide of the worm is the distance a position on the thread travels in the course of one revolution of the worm gear. The backlash measurement need to be manufactured in a handful of diverse areas on the gear wheel, as a massive sum of backlash indicates tooth spacing.

A double-throat worm gear is made for large-load purposes. It provides the tightest relationship in between worm and equipment. It is vital to mount a worm gear assembly accurately. The keyway design and style calls for numerous details of contact, which block shaft rotation and assist transfer torque to the equipment. Soon after deciding the area of the keyway, a hole is drilled into the hub, which is then screwed into the equipment.

The twin-threaded style of worm gears allows them to withstand heavy masses with no slipping or tearing out of the worm. A double-throat worm gear offers the tightest link among worm and equipment, and is therefore excellent for hoisting apps. The self-locking mother nature of the worm gear is one more edge. If the worm gears are created nicely, they are superb for lowering speeds, as they are self-locking.

When choosing a worm, the quantity of threads that a worm has is crucial. Thread commences decide the reduction ratio of a pair, so the greater the threads, the increased the ratio. The very same is true for the worm helix angles, which can be 1, two, or 3 threads prolonged. This differs in between a single thread and a double-throat worm equipment, and it is crucial to take into account the helix angle when selecting a worm.

Double-throat worm gears vary in their profile from the genuine equipment. Double-throat worm gears are especially beneficial in purposes in which sounds is an problem. In addition to their low sounds, worm gears can absorb shock loads. A double-throat worm gear is also a well-liked decision for a lot of different types of purposes. These gears are also typically utilized for hoisting products. Its tooth profile is various from that of the actual equipment.

Bronze or aluminum worm shafts

When picking a worm, a number of items should be kept in brain. The content of the shaft must be either bronze or aluminum. The worm by itself is the principal element, but there are also addendum gears that are available. The whole amount of enamel on equally the worm and the addendum gear ought to be better than forty. The axial pitch of the worm needs to match the circular pitch of the more substantial equipment.

The most common substance used for worm gears is bronze simply because of its desirable mechanical homes. Bronze is a broad phrase referring to different copper alloys, like copper-nickel and copper-aluminum. Bronze is most generally designed by alloying copper with tin and aluminum. In some circumstances, this combination generates brass, which is a related metal to bronze. The latter is much less costly and suited for light-weight masses.

There are a lot of advantages to bronze worm gears. They are sturdy and sturdy, and they supply excellent use-resistance. In distinction to steel worms, bronze worm gears are quieter than their counterparts. They also require no lubrication and are corrosion-resistant. Bronze worms are well-liked with modest, gentle-excess weight machines, as they are effortless to sustain. You can read through far more about worm gears in CZPT’s CZPT.

Though bronze or aluminum worm shafts are the most widespread, equally materials are similarly suitable for a range of apps. A bronze shaft is usually named bronze but may really be brass. Historically, worm gears had been created of SAE sixty five gear bronze. Nevertheless, more recent resources have been introduced. SAE 65 equipment bronze (UNS C90700) remains the preferred substance. For higher-volume programs, the substance savings can be considerable.

Both types of worms are in essence the exact same in measurement and form, but the guide on the left and correct tooth surfaces can fluctuate. This enables for exact adjustment of the backlash on a worm with no altering the heart distance among the worm equipment. The various measurements of worms also make them simpler to manufacture and sustain. But if you want an especially little worm for an industrial software, you must consider bronze or aluminum.

Calculation of worm shaft deflection

The centre-line distance of a worm equipment and the quantity of worm tooth perform a critical position in the deflection of the rotor. These parameters need to be entered into the tool in the very same units as the main calculation. The picked variant is then transferred to the main calculation. The deflection of the worm gear can be calculated from the angle at which the worm teeth shrink. The pursuing calculation is helpful for developing a worm gear.

Worm gears are widely used in industrial purposes owing to their substantial transmittable torques and massive equipment ratios. Their hard/gentle materials combination tends to make them ideally suited for a extensive range of programs. The worm shaft is typically made of situation-hardened metal, and the worm wheel is fabricated from a copper-tin-bronze alloy. In most cases, the wheel is the location of speak to with the gear. Worm gears also have a lower deflection, as high shaft deflection can influence the transmission accuracy and enhance use.

One more technique for deciding worm shaft deflection is to use the tooth-dependent bending stiffness of a worm gear’s toothing. By calculating the stiffness of the specific sections of a worm shaft, the stiffness of the whole worm can be established. The approximate tooth location is proven in determine 5.

An additional way to determine worm shaft deflection is by utilizing the FEM technique. The simulation tool employs an analytical product of the worm gear shaft to establish the deflection of the worm. It is based on a two-dimensional product, which is much more suitable for simulation. Then, you require to enter the worm gear’s pitch angle and the toothing to estimate the highest deflection.

Lubrication of worm shafts

In order to shield the gears, worm drives demand lubricants that supply outstanding anti-use protection, higher oxidation resistance, and low friction. Although mineral oil lubricants are extensively used, synthetic foundation oils have better functionality qualities and lower working temperatures. The Arrhenius Price Rule states that chemical reactions double every single ten degrees C. Synthetic lubricants are the greatest choice for these apps.

Synthetics and compounded mineral oils are the most common lubricants for worm gears. These oils are formulated with mineral basestock and 4 to 6 per cent synthetic fatty acid. Surface-lively additives give compounded gear oils excellent lubricity and stop sliding dress in. These oils are suited for large-velocity apps, including worm gears. Nonetheless, synthetic oil has the drawback of currently being incompatible with polycarbonate and some paints.

Synthetic lubricants are expensive, but they can improve worm gear effectiveness and running life. Artificial lubricants typically slide into two groups: PAO artificial oils and EP artificial oils. The latter has a increased viscosity index and can be used at a range of temperatures. Artificial lubricants typically incorporate anti-dress in additives and EP (anti-wear).

Worm gears are frequently mounted above or beneath the gearbox. The proper lubrication is crucial to guarantee the proper mounting and procedure. Oftentimes, insufficient lubrication can cause the device to fall short quicker than envisioned. Due to the fact of this, a technician might not make a link in between the absence of lube and the failure of the device. It is important to comply with the manufacturer’s suggestions and use high-high quality lubricant for your gearbox.

Worm drives reduce backlash by reducing the engage in amongst equipment enamel. Backlash can trigger damage if unbalanced forces are launched. Worm drives are light-weight and tough since they have small relocating elements. In addition, worm drives are minimal-sound and vibration. In addition, their sliding motion scrapes absent excess lubricant. The continuous sliding motion generates a large volume of heat, which is why superior lubrication is vital.

Oils with a large film toughness and outstanding adhesion are excellent for lubrication of worm gears. Some of these oils include sulfur, which can etch a bronze equipment. In purchase to avoid this, it is imperative to use a lubricant that has large film strength and prevents asperities from welding. The excellent lubricant for worm gears is 1 that gives superb film power and does not contain sulfur.

China Hot selling Worm Gear Bare Shaft Full PTFE Lined Butterfly Valve Pn10 Pn16 Class150 with high quality

Merchandise Description

Solution Characteristic:

a hundred% bi-directional restricted shut-off.

Installationwithout restriction in direction of flow.

Lowered weight and total proportions.

Lower force decline and lowered CZPT expenses.

Higher Kv / Cv values.

Effortless to thoroughly clean and disinfect for potable drinking water programs and so on.

Self cleansing ( no residue will be trapped ).

Great resistance to corrosion.

Preservative

Main Material:

**Organization INTRODUCTION

**Style & Growth ability — SolidWorks, Pro / E, AutoCAD and so on

**Dimension Measurement &Inspection

**Assembly Workshop

**Packaging

**Certificates — CE ISO WRAS ACS certificates

Worm Equipment Motors

Worm equipment motors are often desired for quieter procedure since of the easy sliding movement of the worm shaft. In contrast to gear motors with tooth, which may click as the worm turns, worm gear motors can be set up in a silent location. In this report, we will discuss about the CZPT whirling procedure and the various sorts of worms accessible. We are going to also talk about the advantages of worm gear motors and worm wheel.

worm equipment

In the situation of a worm equipment, the axial pitch of the ring pinion of the corresponding revolving worm is equal to the round pitch of the mating revolving pinion of the worm equipment. A worm with one particular start is identified as a worm with a direct. This qualified prospects to a scaled-down worm wheel. Worms can work in limited areas since of their modest profile.

Normally, a worm equipment has high performance, but there are a few negatives. Worm gears are not suggested for substantial-warmth programs since of their substantial amount of rubbing. A entire-fluid lubricant film and the low dress in level of the gear minimize friction and dress in. Worm gears also have a reduced put on price than a standard gear. The worm shaft and worm gear is also a lot more productive than a standard equipment.

The worm equipment shaft is cradled inside of a self-aligning bearing block that is hooked up to the gearbox casing. The eccentric housing has radial bearings on both ends, enabling it to interact with the worm equipment wheel. The travel is transferred to the worm gear shaft via bevel gears 13A, one fastened at the finishes of the worm equipment shaft and the other in the centre of the cross-shaft.

worm wheel

In a worm gearbox, the pinion or worm equipment is centered between a geared cylinder and a worm shaft. The worm gear shaft is supported at both conclude by a radial thrust bearing. A gearbox’s cross-shaft is set to a appropriate generate means and pivotally attached to the worm wheel. The input generate is transferred to the worm equipment shaft ten by means of bevel gears 13A, one of which is fastened to the end of the worm gear shaft and the other at the centre of the cross-shaft.

Worms and worm wheels are obtainable in many resources. The worm wheel is made of bronze alloy, aluminum, or metal. Aluminum bronze worm wheels are a excellent selection for higher-speed purposes. Forged iron worm wheels are low cost and appropriate for light loads. MC nylon worm wheels are extremely put on-resistant and machinable. Aluminum bronze worm wheels are accessible and are good for purposes with significant use conditions.

When developing a worm wheel, it is essential to figure out the right lubricant for the worm shaft and a corresponding worm wheel. A suitable lubricant must have a kinematic viscosity of 300 mm2/s and be used for worm wheel sleeve bearings. The worm wheel and worm shaft must be correctly lubricated to ensure their longevity.

Multi-start worms

A multi-begin worm equipment screw jack brings together the benefits of several commences with linear output speeds. The multi-start worm shaft minimizes the results of solitary start off worms and big ratio gears. Both varieties of worm gears have a reversible worm that can be reversed or stopped by hand, relying on the application. The worm gear’s self-locking capability is dependent on the guide angle, stress angle, and friction coefficient.

A solitary-start worm has a solitary thread running the duration of its shaft. The worm developments a single tooth per revolution. A multi-start off worm has multiple threads in each of its threads. The gear reduction on a multi-start worm is equal to the amount of enamel on the gear minus the amount of commences on the worm shaft. In general, a multi-start off worm has two or a few threads.

Worm gears can be quieter than other sorts of gears because the worm shaft glides rather than clicking. This can make them an outstanding choice for applications the place sound is a concern. Worm gears can be made of softer substance, creating them a lot more sounds-tolerant. In addition, they can face up to shock hundreds. When compared to gears with toothed teeth, worm gears have a decrease noise and vibration fee.

CZPT whirling procedure

The CZPT whirling approach for worm shafts raises the bar for precision equipment machining in small to medium production volumes. The CZPT whirling process lowers thread rolling, increases worm quality, and offers decreased cycle occasions. The CZPT LWN-90 whirling machine attributes a metal mattress, programmable drive tailstock, and 5-axis interpolation for elevated accuracy and high quality.

Its 4,000-rpm, 5-kW whirling spindle creates worms and different varieties of screws. Its outer diameters are up to 2.5 inches, whilst its length is up to twenty inches. Its dry-reducing method utilizes a vortex tube to deliver chilled compressed air to the chopping point. Oil is also included to the mixture. The worm shafts created are free of undercuts, lowering the sum of machining needed.

Induction hardening is a procedure that requires edge of the whirling process. The induction hardening approach makes use of alternating present (AC) to cause eddy currents in metallic objects. The increased the frequency, the larger the floor temperature. The electrical frequency is monitored by means of sensors to prevent overheating. Induction heating is programmable so that only specific parts of the worm shaft will harden.

Widespread tangent at an arbitrary point on each surfaces of the worm wheel

A worm gear consists of two helical segments with a helix angle equivalent to ninety levels. This form makes it possible for the worm to rotate with far more than 1 tooth for each rotation. A worm’s helix angle is generally near to ninety levels and the physique size is pretty extended in the axial direction. A worm gear with a lead angle g has comparable houses as a screw equipment with a helix angle of ninety degrees.

The axial cross segment of a worm gear is not conventionally trapezoidal. Instead, the linear part of the oblique aspect is replaced by cycloid curves. These curves have a typical tangent in close proximity to the pitch line. The worm wheel is then formed by gear cutting, resulting in a equipment with two meshing surfaces. This worm gear can rotate at substantial speeds and nonetheless run quietly.

A worm wheel with a cycloid pitch is a more effective worm equipment. It reduces friction amongst the worm and the gear, resulting in better longevity, improved working performance, and reduced noise. This pitch line also aids the worm wheel engage more evenly and effortlessly. Additionally, it helps prevent interference with their visual appeal. It also can make worm wheel and gear engagement smoother.

Calculation of worm shaft deflection

There are numerous methods for calculating worm shaft deflection, and every technique has its personal established of negatives. These commonly used strategies offer good approximations but are insufficient for deciding the true worm shaft deflection. For example, these methods do not account for the geometric modifications to the worm, these kinds of as its helical winding of enamel. In addition, they overestimate the stiffening effect of the gearing. Consequently, effective slim worm shaft designs require other methods.

Luckily, numerous approaches exist to establish the highest worm shaft deflection. These techniques use the finite element method, and include boundary circumstances and parameter calculations. Here, we search at a pair of techniques. The very first method, DIN 3996, calculates the optimum worm shaft deflection based on the test results, while the second one, AGMA 6022, utilizes the root diameter of the worm as the equivalent bending diameter.

The next method focuses on the basic parameters of worm gearing. We’ll take a closer search at each. We will analyze worm gearing enamel and the geometric elements that affect them. Typically, the range of worm gearing tooth is one to 4, but it can be as large as twelve. Choosing the teeth ought to rely on optimization needs, which includes performance and weight. For example, if a worm gearing needs to be smaller than the preceding product, then a little variety of enamel will suffice.

China supplier Solid Output Shaft Worm Gear Speed Reducer with Good quality

Merchandise Description

NMRV worm gearbox motor

NMRV series worm gear reducer:

Its framework,outline and installation dimensions as properly as performance are exact same with that of

Europe an items,they are interchangeable,and the supplies and machining method are superior internationally.The product is highlighted by:

one.Reduced noise and temperature rise.

two.High bearing ability,clean run and lengthy services lifestyle.

three.ompact construction,samll volume,light weight,stunning form and straightforward to put in.

4.Can run continuously below server setting,and has a great trustworthiness.

GPHQ NMRV aluminum worm gearbox motor particulars:

FAQ

one, Q:what’s your MOQ for ac gearbox motor ?

A: 1pc is ok for every variety electric equipment box motor

2, Q: What about your guarantee for your induction speed reducer motor ?

A: 1 year ,but besides gentleman-created ruined

three, Q: which payment way you can take ?

A: TT, western union .

four, Q: how about your payment way ?

A: one hundred%payment in superior significantly less $5000 ,30% payment in sophisticated payment , 70% payment prior to sending more than $5000.

five, Q: how about your packing of velocity reduction motor ?

A: plywood scenario ,if dimension is modest ,we will pack with pallet for much less 1 container

six, Q: What info ought to be given, if I buy electric powered helical geared motor from you ?

A: rated electricity, ratio or output speed,type ,voltage , mounting way , quantity , if a lot more is far better.

How to Figure out the Quality of a Worm Shaft

There are a lot of positive aspects of a worm shaft. It is less complicated to manufacture, as it does not need guide straightening. Amid these benefits are ease of upkeep, decreased cost, and relieve of set up. In addition, this kind of shaft is significantly considerably less inclined to hurt owing to guide straightening. This article will examine the distinct factors that decide the good quality of a worm shaft. It also discusses the Dedendum, Root diameter, and Use load potential.

Root diameter

There are numerous choices when picking worm gearing. The variety is dependent on the transmission used and production prospects. The standard profile parameters of worm gearing are described in the expert and firm literature and are used in geometry calculations. The selected variant is then transferred to the major calculation. Nevertheless, you need to just take into account the energy parameters and the gear ratios for the calculation to be exact. Listed here are some suggestions to decide on the correct worm gearing.

The root diameter of a worm equipment is calculated from the heart of its pitch. Its pitch diameter is a standardized worth that is established from its pressure angle at the level of zero gearing correction. The worm equipment pitch diameter is calculated by incorporating the worm’s dimension to the nominal middle distance. When defining the worm equipment pitch, you have to preserve in head that the root diameter of the worm shaft need to be smaller than the pitch diameter.

Worm gearing demands enamel to evenly distribute the dress in. For this, the tooth facet of the worm have to be convex in the regular and centre-line sections. The form of the tooth, referred to as the evolvent profile, resembles a helical equipment. Normally, the root diameter of a worm gear is much more than a quarter inch. Even so, a fifty percent-inch variation is acceptable.

An additional way to calculate the gearing performance of a worm shaft is by seeking at the worm’s sacrificial wheel. A sacrificial wheel is softer than the worm, so most use and tear will take place on the wheel. Oil investigation reports of worm gearing models almost usually show a higher copper and iron ratio, suggesting that the worm’s gearing is ineffective.

Dedendum

The dedendum of a worm shaft refers to the radial length of its tooth. The pitch diameter and the small diameter figure out the dedendum. In an imperial technique, the pitch diameter is referred to as the diametral pitch. Other parameters contain the experience width and fillet radius. Encounter width describes the width of the equipment wheel without having hub projections. Fillet radius steps the radius on the suggestion of the cutter and varieties a trochoidal curve.

The diameter of a hub is calculated at its outer diameter, and its projection is the distance the hub extends over and above the gear encounter. There are two kinds of addendum teeth, one with short-addendum enamel and the other with long-addendum tooth. The gears themselves have a keyway (a groove machined into the shaft and bore). A important is fitted into the keyway, which matches into the shaft.

Worm gears transmit movement from two shafts that are not parallel, and have a line-toothed design and style. The pitch circle has two or far more arcs, and the worm and sprocket are supported by anti-friction roller bearings. Worm gears have large friction and use on the tooth teeth and restraining surfaces. If you would like to know much more about worm gears, just take a appear at the definitions under.

CZPT’s whirling process

Whirling method is a modern day production approach that is replacing thread milling and hobbing processes. It has been capable to minimize manufacturing charges and guide times even though generating precision equipment worms. In addition, it has lowered the need to have for thread grinding and floor roughness. It also minimizes thread rolling. This is much more on how CZPT whirling method works.

The whirling procedure on the worm shaft can be utilized for producing a selection of screw sorts and worms. They can produce screw shafts with outer diameters of up to 2.5 inches. In contrast to other whirling procedures, the worm shaft is sacrificial, and the method does not require machining. A vortex tube is used to produce chilled compressed air to the reducing point. If required, oil is also added to the mix.

Another technique for hardening a worm shaft is named induction hardening. The method is a high-frequency electrical method that induces eddy currents in metallic objects. The higher the frequency, the much more surface warmth it generates. With induction heating, you can program the heating approach to harden only certain locations of the worm shaft. The size of the worm shaft is typically shortened.

Worm gears provide several rewards over regular gear sets. If utilized properly, they are reliable and hugely effective. By adhering to proper set up suggestions and lubrication guidelines, worm gears can supply the exact same reliable provider as any other kind of gear established. The article by Ray Thibault, a mechanical engineer at the College of Virginia, is an outstanding guide to lubrication on worm gears.

Wear load potential

The put on load capacity of a worm shaft is a key parameter when deciding the efficiency of a gearbox. Worms can be made with various gear ratios, and the style of the worm shaft should reflect this. To decide the dress in load capability of a worm, you can check out its geometry. Worms are normally manufactured with teeth ranging from one to 4 and up to twelve. Picking the appropriate quantity of enamel relies upon on several elements, including the optimisation requirements, such as efficiency, bodyweight, and centre-line distance.

Worm equipment tooth forces enhance with elevated electricity density, creating the worm shaft to deflect a lot more. This minimizes its wear load ability, lowers efficiency, and boosts NVH behavior. Advances in lubricants and bronze materials, combined with far better production top quality, have enabled the ongoing increase in electricity density. Individuals three factors blended will figure out the wear load capacity of your worm equipment. It is crucial to consider all a few variables prior to choosing the right equipment tooth profile.

The bare minimum variety of equipment teeth in a equipment is dependent on the force angle at zero gearing correction. The worm diameter d1 is arbitrary and depends on a acknowledged module value, mx or mn. Worms and gears with various ratios can be interchanged. An involute helicoid ensures proper get in touch with and form, and offers increased accuracy and lifestyle. The involute helicoid worm is also a important ingredient of a equipment.

Worm gears are a sort of historical equipment. A cylindrical worm engages with a toothed wheel to reduce rotational speed. Worm gears are also used as prime movers. If you happen to be seeking for a gearbox, it might be a very good selection. If you are contemplating a worm gear, be sure to check its load ability and lubrication requirements.

NVH behavior

The NVH behavior of a worm shaft is identified employing the finite component strategy. The simulation parameters are outlined employing the finite component technique and experimental worm shafts are when compared to the simulation benefits. The benefits demonstrate that a large deviation exists amongst the simulated and experimental values. In addition, the bending stiffness of the worm shaft is highly dependent on the geometry of the worm equipment toothings. Consequently, an adequate layout for a worm gear toothing can help reduce the NVH (sound-vibration) actions of the worm shaft.

To estimate the worm shaft’s NVH conduct, the main axes of moment of inertia are the diameter of the worm and the number of threads. This will impact the angle between the worm enamel and the powerful length of every tooth. The length between the principal axes of the worm shaft and the worm gear is the analytical equivalent bending diameter. The diameter of the worm gear is referred to as its successful diameter.

The increased power density of a worm equipment outcomes in enhanced forces acting on the corresponding worm equipment tooth. This prospects to a corresponding improve in deflection of the worm equipment, which negatively influences its effectiveness and wear load ability. In addition, the rising electrical power density calls for improved manufacturing quality. The steady advancement in bronze resources and lubricants has also facilitated the ongoing improve in power density.

The toothing of the worm gears establishes the worm shaft deflection. The bending stiffness of the worm equipment toothing is also calculated by employing a tooth-dependent bending stiffness. The deflection is then converted into a stiffness worth by making use of the stiffness of the specific sections of the worm shaft. As revealed in figure 5, a transverse section of a two-threaded worm is revealed in the determine.

China supplier Wpa/Wps/Wpks/Wpka/Wpwka Shaft Mounted Gearbox, Worm Gear Reducer with Motor with Great quality

Item Description

Wpa/wps/wpks/wpka/wpwka shaft mounted gearbox, worm gear reducer with motor

Functions:

1. Compact structure and straightforward assembly

two. Broad velocity ranges and higher torque

3. Minimal sounds, good sealing performance, substantial performance

four. Stable and safe, prolonged life time, common

5. Multi-composition, a variety of assembling techniques

Item image:

Specification:

FAQ

Q: Can you make the reducer with customization?

A: Indeed, we can customize for each your ask for, like flange, shaft, configuration, material, and many others.

Q: Do you give samples?

A: Yes. Sample is accessible for screening.

Q: What is your MOQ?

A: It is 10pcs for the beginning of our business.

Q: What is actually your guide time?

A: Normal merchandise need to have 5-30days, a bit for a longer time for customized goods.

Q: Do you give technologies support?

A: Of course. Our business have layout and growth crew, we can give technology assist if you

need to have.

Q: How to ship to us?

A: It is offered by air, or by sea, or by train.

Q: How to spend the funds?

A: T/T and L/C is favored, with diverse currency, including USD, EUR, RMB, and so forth.

Q: How can I know the item is suitable for me?

A: >1ST affirm drawing and specification >2nd test sample >3rd start mass manufacturing.

Q: Can I come to your firm to go to?

A: Sure, you are welcome to pay a visit to us at any time.

Q: How shall we make contact with you?

A: You can send inquiry directly, and we will react inside 24 hrs.

What Is a Worm Gear Reducer?

If you have in no way observed a worm equipment reducer ahead of, you might be lacking out! Learn more about these outstanding gears and their purposes by reading through this article! In addition to worm equipment reducers, learn about worms and how they are made. You may also learn what varieties of machines can benefit from worm gears, this sort of as rock crushers and elevators. The subsequent information will support you comprehend what a worm gear reducer is and how to discover one particular in your location.

Standard worm shaft

A common worm has two shafts, one particular for advancing and 1 for receding, which sort the axial pitch of the gear. Usually, there are 8 normal axial pitches, which create a standard dimension for worm manufacturing and inspection. The axial pitch of the worm equals the circular pitch of the gear in the central airplane and the grasp lead cam’s radial pitch. A single set of adjust gears and one particular grasp direct cam are employed to make every dimension of worm.

Worm equipment is typically utilised to manufacture a worm shaft. It is a trustworthy and efficient equipment reduction technique that does not go when the electrical power is removed. Typical worm gears appear in normal sizes as properly as assisted methods. Makers can be located on the web. Outlined beneath are some frequent materials for worm gears. There are also several choices for lubrication. The worm equipment is generally manufactured from case hardened steel or bronze. Non-metallic materials are also used in mild-responsibility apps.

A self-locking worm gear helps prevent the worm from moving backwards. Typical worm gears are usually self-locking when the lead angle is less than 11 degrees. Nonetheless, this attribute can be harmful to techniques that call for reverse sensitivity. If the direct angle is less than 4 levels, again-driving is unlikely. Nevertheless, if are unsuccessful-safe safety is a prerequisite, back again-driving worm gears should have a constructive brake to keep away from reverse motion.

Worm gears are frequently used in transmission applications. They are a much more successful way to lessen the velocity of a equipment compared to typical gear sets. Their diminished velocity is feasible thanks to their lower ratio and handful of components. As opposed to traditional gear sets, worm gears require considerably less maintenance and reduced mechanical failure than a traditional gear set. While they call for less components, worm gears are also more resilient than traditional equipment sets.

There are two sorts of worm tooth forms. Convex and involute helicoids have different kinds of enamel. The previous makes use of a straight line to intersect the involute worm producing line. The latter, on the other hand, uses a trapezoid primarily based on the central cross section of the root. Equally of these tooth kinds are employed in the production of worms. And they have a variety of variations in pitch diameter.

Kinds of worms

Worms have several kinds of tooth. For usefulness in creation, a trapezoid-primarily based tooth type is employed. Other varieties include an involute helicoidal or a convolute worm producing a line. The pursuing is a description of every type. All kinds are comparable, and some might be favored above other people. Listed beneath are the three most common worm shaft types. Each type has its possess benefits and down sides.

Discrete compared to parallel axis: The layout of a worm gear establishes its ratio of torque. It is a blend of two diverse metals – a single for the worm and 1 for the wheel – which helps it soak up shock hundreds. Design tools and off-road automobiles generally require various torques to maneuver more than distinct terrain. A worm equipment system can support them maneuver in excess of uneven terrain with out creating extreme put on.

Worm equipment units have the optimum ratio. The sliding action of the worm shaft outcomes in a substantial self-locking torque. Relying on the angle of inclination and friction, a worm equipment can get to up to one hundred:1! Worm gears can be created of different resources depending on their inclination and friction angle. Worm gears are also beneficial for equipment reduction purposes, this kind of as lubrication or grinding. Even so, you need to consider that heavier gears tend to be more difficult to reverse than lighter kinds.

Metal alloy: Stainless steel, brass, and aluminum bronze are widespread components for worm gears. All 3 kinds have unique advantages. A bronze worm gear is typically composed of a combination of copper, zinc, and tin. A bronze shaft is a lot more corrosive than a brass one particular, but it is a tough and corrosion-resistant selection. Metallic alloys: These components are utilized for equally the worm wheel.

The performance of worm gears depends on the assembly circumstances and the lubricant. A 30:1 ratio decreases the efficiency to 81:1%. A worm gear is more productive at increased ratios than an helical equipment, but a thirty:1 ratio minimizes the performance to eighty one%. A helical gear reduces pace although preserving torque to close to 15% of the authentic pace. The distinction in efficiency amongst worm equipment and helical gear is about half an hour!

Strategies of producing worm shafts

Many methods of production worm shafts are obtainable in the market place. One-pointed lathe resources or end mills are the most well-known methods for producing worms. These equipment are able of making worms with diverse strain angles dependent on their diameter, the depth of thread, and the grinding wheel’s diameter. The diagram underneath exhibits how various strain angles influence the profile of worms produced employing different chopping instruments.

The strategy for producing worm shafts includes the approach of setting up the suitable outer diameter of a frequent worm shaft blank. This may possibly contain taking into consideration the quantity of reduction ratios in a loved ones, the length between the worm shaft and the gear set centre, as effectively as the torques concerned. These procedures are also referred to as ‘thread assembly’. Every single process can be additional refined if the wanted axial pitch can be reached.

The axial pitch of a worm must match the circular pitch of the more substantial gear. This is called the pitch. The pitch diameter and axial pitch need to be equivalent. Worms can be left-handed or proper-handed. The direct, which refers to the distance a point on the thread travels in the course of 1 revolution of the worm, is described by its angle of tangent to the helix on the pitch of the cylinder.

Worm shafts are frequently manufactured employing a worm equipment. Worm gears can be used in various applications since they offer you wonderful adjustment and substantial equipment reduction. They can be created in the two normal dimensions and assisted techniques. Worm shaft producers can be identified on-line. Alternatively, you can get in touch with a producer right to get your worm gears made. The approach will take only a few minutes. If you are hunting for a manufacturer of worm gears, you can browse a listing.

Worm gears are created with hardened steel. The worm wheel and equipment are yellow in coloration. A compounded oil with rust and oxidation inhibitors is also employed to make worm gears. These oils adhere to the shaft walls and make a protective barrier between the surfaces. If the compounded oil is utilized correctly, the worm gear will minimize the sound in a motor, ensuing in a smoother performance.

apps for worm equipment reducers

Worm gears are extensively employed in power transmission apps, supplying a compact, substantial reduction, reduced-pace generate. To figure out the torque ratio of worm gears, a numerical design was designed that makes use of the equation of displacement compatibility and the affect coefficient strategy, which supplies rapidly computing. The numerical model also incorporates bending deflections of the equipment surfaces and the mating surfaces. It is dependent on the Boussinesq principle, which calculates neighborhood get in touch with deformations.

Worm gears can be made to be correct or still left-handed, and the worm can flip possibly clockwise or counter-clockwise. An inside helical gear requires the identical hand to operate each elements. In distinction, an external helical gear should be operated by the reverse hand. The same theory applies to worm gears in other applications. The torque and energy transferred can be huge, but worm gears are ready to cope with large reductions in equally instructions.

Worm gears are incredibly helpful in industrial machinery types. They lessen sound amounts, conserve place, and give equipment added precision and fast-stopping capabilities. Worm gears are also obtainable in compact variations, generating them excellent for hoisting apps. This variety of gear reducer is employed in industrial configurations exactly where place is an situation. Its more compact size and significantly less sound can make it ideal for programs that need the machine to quit swiftly.

A double-throated worm equipment provides the highest load ability while nonetheless remaining compact. The double-throated edition characteristics concave teeth on the two worm and equipment, doubling the get in touch with region between them. Worm gears are also valuable for reduced to average-horsepower apps, and their higher ratios, substantial output torque, and substantial velocity reduction make them a fascinating option for several apps. Worm gears are also quieter than other varieties of gears, minimizing the sound and vibrations that they cause.

Worm gears have many advantages above other types of gears. They have large ranges of conformity and can be categorised as a screw pair inside of a decrease-pair gear loved ones. Worm gears are also recognized to have a high diploma of relative sliding. Worm gears are typically created of hardened steel or phosphor-bronze, which provides great floor end and rigid positioning. Worm gears are lubricated with specific lubricants that have surface-energetic additives. Worm gear lubrication is a combined lubrication approach and leads to delicate put on and tear.

China OEM High Speed Power Small NMRV150 Worm Gear Speed Reducer For Aluminum Alloy Gearbox Belt Conveyor Input Shaft Textile Machine with Good quality

Warranty: 1 many years

Relevant Industries: Developing Materials Stores, Manufacturing Plant, Equipment Mend Retailers, Foods & Beverage Manufacturing facility, Farms, Retail, Printing Retailers, Construction works , Energy & Mining, Meals & Beverage Stores, Quick CZPT Transmission gearbox HW19710 HW19712 Servo Motor

Personalized help: OEM, ODM, OBM

Gearing Arrangement: Planetary

Output Torque: 12.5-forty N.M

Enter Pace: -3000 RPM

Output Velocity: 30-one thousand RPM

Item identify: NMRV150Flange Enter Variety

Ratio: 500

Double worm gear device codes: DRV

The length of centre to centre: fifty/seventy five

Lubricating sort: Daily life lubrication

The extension worm shaft: E

Output flange: F

Set up place: VS1

The body of moter: 80B5

Life span: 20000h

Packaging Specifics: Carton/wood box packaging

Port: ZheJiang , HangZhou, ZheJiang , HangZhou, HangZhou or other china port.

Principal Classes Solution Overview

Specification

ModelNMRV150 Flange Input Type Reduction ratio500

Match motorMatch any brand of servo motor or steppr motorHS CODE 8483409000Protection quality IP65Lifetime20000hLubricating typeLife lubrication Support Related Products About Us FAQ

Q1: What’re your primary merchandise?A1: High Precision Planetary Gearbox Hollow Rotating Platform Precision Steering Box Gearbox for valves in cast iron and carbon steel Worm Speed Reducer Worm Screw Jack R/K/F/S GearboxQ2: What industries are your gearboxes being utilised in?A2: Gearboxes are extensively used in the regions of robotics, textile, foods processing, beverage, chemical business, escalator, computerized storage tools, metallurgy, solitary plough bcs full 25hp agriculture powering 2 wheel hand walking tractor with implements environmental defense, logistics, and so on.Q3: Can you supply OEM or ODM provider?A3: Yes, we are a skilled maker so we can do customized orders.Q4: How to select a design?A4: We have 1-1 provider crew for model assortment, and we can offer CAD drawings and 3D types in 5 minutes with technological details of necessary output torque, output pace and motor parameters and many others. So just make contact with us.Q5: What information shall we give just before placing a buy buy?A5: We understand your wants from the subsequent info: a) Sort of the gearbox, ratio, enter and output type, input flange, mounting place, GTM gearbox rotary mower gearbox agricultural farm gearbox and motor information etc.b) Housing colour.c) Purchase quantity.d) Other special requirements.Q6: How long is the delivery time?A6: Most planetary gearboxes are in stock. 7 doing work days for worm velocity reducer and worm screw jack, fifteen operating days for R/K/F/S gearbox.

What Is a Gearbox?

There are a number of aspects to contemplate when selecting a gearbox. Backlash, for example, is a consideration, as it is the angle at which the output shaft can rotate with no the input shaft shifting. Although this just isn’t essential in purposes with no load reversals, it is essential for precision applications involving load reversals. Examples of these applications incorporate automation and robotics. If backlash is a concern, you might want to appear at other aspects, such as the quantity of tooth in each equipment.

Function of a gearbox

A gearbox is a mechanical unit that is made up of a chain or established of gears. The gears are mounted on a shaft and are supported by rolling element bearings. These gadgets change the speed or torque of the machine they are employed in. Gearboxes can be used for a vast assortment of programs. Right here are some illustrations of how gearboxes function. Study on to uncover much more about the gears that make up a gearbox.

Irrespective of the variety of transmission, most gearboxes are outfitted with a secondary equipment and a main one. While the equipment ratios are the exact same for both the major and secondary transmission, the gearboxes could vary in dimensions and efficiency. Substantial-functionality racing vehicles typically use a gearbox with two green and one particular blue gear. Gearboxes are typically mounted in the entrance or rear of the motor.

The primary function of a gearbox is to transfer torque from 1 shaft to an additional. The ratio of the driving gear’s enamel to the acquiring member determines how much torque is transmitted. A large gear ratio will cause the major shaft to revolve at a slower speed and have a higher torque in comparison to its counter shaft. Conversely, a low equipment ratio will enable the motor vehicle to turn at a decrease speed and produce a reduce torque.

A conventional gearbox has input and output gears. The countershaft is related to a universal shaft. The enter and output gears are arranged to match the pace and torque of each and every other. The equipment ratio decides how quick a vehicle can go and how much torque it can make. Most conventional transmissions use 4 equipment ratios, with one reverse gear. Some have two shafts and 3 inputs. Even so, if the equipment ratios are higher, the engine will encounter a decline of torque.

In the research of gearbox functionality, a huge quantity of data has been gathered. A very ambitious segmentation procedure has yielded nearly 20,000 function vectors. These benefits are the most comprehensive and comprehensive of all the offered knowledge. This investigation has a twin curse – the first is the big volume of info collected for the purpose of characterization, while the 2nd is the large dimensionality. The latter is a complication that arises when the experimental gearbox is not designed to complete properly.

Bzvacklash

The principal operate of a gearhead is to multiply a second of force and generate a mechanical benefit. However, backlash can lead to a selection of concerns for the method, which includes impaired positioning accuracy and lowered general performance. A zero backlash gearbox can eliminate movement losses triggered by backlash and boost general program overall performance. Right here are some frequent issues associated with backlash in gearheads and how to fix them. Soon after you understand how to fix gearbox backlash, you are going to be capable to design and style a device that meets your demands.

To decrease gearbox backlash, many designers try to lower the centre length of the gears. This removes place for lubrication and promotes extreme tooth mesh, which leads to untimely mesh failure. To decrease gearbox backlash, a equipment manufacturer might individual the two elements of the gear and modify the mesh centre length among them. To do this, rotate a single gear with respect to the set gear, while adjusting the other gear’s efficient tooth thickness.

A number of manufacturing procedures could introduce problems, and decreasing tooth thickness will lessen this mistake. Gears with bevel teeth are a primary instance of this. This kind of equipment characteristics a modest quantity of teeth in comparison to its mating gear. In addition to reducing tooth thickness, bevel gears also lessen backlash. Even though bevel gears have fewer tooth than their mating gear, all of their backlash allowance is applied to the bigger equipment.

A gear’s backlash can impact the effectiveness of a gearbox. In an ideal gear, the backlash is zero. But if there is way too considerably, backlash can cause injury to the gears and result in it to malfunction. Therefore, the aim of gearbox backlash is to decrease this difficulty. Nonetheless, this may possibly require the use of a micrometer. To figure out how considerably gearbox backlash you need, you can use a dial gauge or feeler gauge.

If you have been searching for a way to reduce backlash, a gearbox’s backlash might be the answer. Nonetheless, backlash is not a revolt in opposition to the maker. It is an error in movement that occurs normally in equipment systems that change course. If it is left unaccounted for, it can lead to main gear degradation and even compromise the whole method. In this report, we are going to clarify how backlash impacts gears and how it has an effect on the overall performance of a gearbox.

Design and style

The design of gearboxes is composed of a assortment of elements, including the variety of materials used, electrical power specifications, pace and reduction ratio, and the application for which the unit is meant. The process of designing a gearbox typically commences with a description of the equipment or gearbox and its meant use. Other important parameters to consider throughout gearbox style consist of the size and fat of the equipment, its general gear ratio and quantity of reductions, as effectively as the lubrication methods employed.

In the course of the design approach, the consumer and provider will take part in different layout testimonials. These contain concept or preliminary layout assessment, producing design and style validation, vital style overview, and final design and style review. The consumer could also initiate the approach by initiating a DFMEA. After acquiring the preliminary design acceptance, the design and style will go by means of several iterations before the finalized style is frozen. In some instances, the client will need a DFMEA of the gearbox.

The speed increaser gearboxes also need special style concerns. These gearboxes usually function at large speeds, leading to difficulties with gear dynamics. Additionally, the high speeds of the device increase frictional and drag forces. A suitable layout of this part must minimize the impact of these forces. To remedy these difficulties, a gearbox ought to integrate a brake method. In some situations, an exterior drive might also increase frictional forces.

Different sorts of gear arrangements are utilised in gearboxes. The design and style of the teeth of the gears plays a considerable part in defining the kind of equipment arrangement in the gearbox. Spur gear is an example of a equipment arrangement, which has tooth that run parallel to the axis of rotation. These gears provide higher equipment ratios and are often utilized in a number of levels. So, it is attainable to develop a gearbox that meets the wants of your application.

The design and style of gearboxes is the most intricate process in the engineering method. These complicated products are created of several types of gears and are mounted on shafts. They are supported by rolling element bearings and are used for a variety of programs. In standard, a gearbox is employed to lessen pace and torque and adjust route. Gearboxes are frequently employed in motor vehicles, but can also be discovered in pedal bicycles and set devices.

Manufacturers

There are many main segments in the gearbox marketplace, like industrial, mining, and automotive. Gearbox manufacturers are required to comprehend the application and user industries to design and style a gearbox that fulfills their specific demands. Simple information of metallurgy is necessary. Multinational firms also provide gearbox options for the electricity era market, shipping sector, and automotive industries. To make their goods a lot more competitive, they need to have to target on solution innovation, geographical enlargement, and consumer retention.

The CZPT Team commenced as a tiny organization in 1976. Given that then, it has become a world-wide reference in mechanical transmissions. Its generation selection contains gears, reduction gearboxes, and geared motors. The business was the initial in Italy to achieve ISO certification, and it carries on to grow into one of the world’s leading manufacturers of creation gearboxes. As the business evolves, CZPT focuses on research and improvement to create far better items.

The agriculture sector utilizes gearboxes to put into action a selection of processes. They are employed in tractors, pumps, and agricultural machinery. The automotive industry utilizes gears in cars, but they are also located in mining and tea processing machinery. Industrial gearboxes also engage in an critical part in feed and speed drives. The gearbox industry has a varied portfolio of producers and suppliers. Right here are some illustrations of gearboxes:

Gearboxes are complicated items of equipment. They must be used appropriately to optimize effectiveness and prolong their lifespan. Producers make use of advanced technology and rigorous good quality management processes to make certain their merchandise fulfill the highest specifications. In addition to production precision and trustworthiness, gearbox manufacturers guarantee that their items are risk-free for use in the production of industrial machinery. They are also employed in place of work machines and medical gear. Even so, the automotive gearbox industry is turning into more and more competitive.