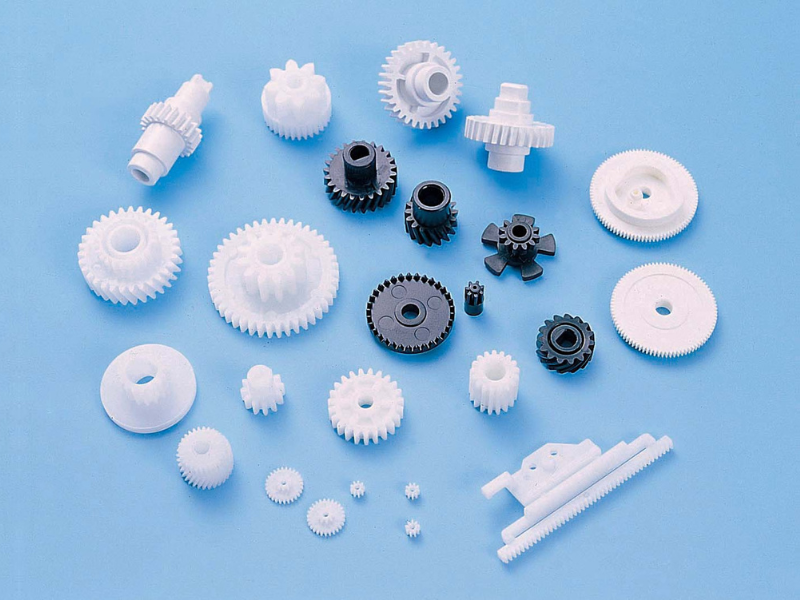

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Our Machine

Product Range

Contact Us /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Plastic |

| Customization: |

Available

|

|

|---|

Can plastic wheels be customized for specific uses or environments?

Yes, plastic wheels can be customized for specific uses or environments to meet unique requirements and applications. Customization options for plastic wheels include:

- 1. Material Selection: Plastic wheels can be manufactured from various types of plastics, each with specific properties. Depending on the application, you can choose the most suitable plastic material to optimize factors like durability, chemical resistance, temperature tolerance, and load-bearing capacity.

- 2. Load Capacity: Custom plastic wheels can be designed with specific load-bearing capabilities in mind. Reinforcements and modifications to the wheel’s structure can be made to increase its load capacity, ensuring it can handle the intended weight.

- 3. Wheel Diameter: The size and diameter of the wheel can be customized to match the terrain and space constraints of the application. Whether you need smaller or larger wheels, customization is possible to ensure a perfect fit.

- 4. Tread Design: The tread pattern on plastic wheels can be tailored to provide optimal traction, stability, and noise reduction for specific environments. Different tread designs are available to suit various surfaces and conditions.

- 5. Bearings: Custom plastic wheels can be equipped with different types of bearings to meet performance requirements. Precision bearings, sealed bearings, or special bearing configurations can be chosen based on the application’s demands.

- 6. Environment-Specific Features: Plastic wheels can be customized with features like corrosion-resistant coatings, anti-static properties, UV resistance, and non-marking materials to accommodate specific environmental conditions.

- 7. Color and Aesthetics: Custom plastic wheels can be produced in various colors and finishes to match the aesthetics of the equipment or environment they are used in. This is common in applications like office furniture and consumer products.

- 8. Mounting Options: Custom wheels can be designed with specific mounting and attachment options to ensure a secure fit with the equipment or vehicle. Custom hubs or axle configurations can be provided.

- 9. Specialized Applications: For highly specialized applications, such as aerospace, healthcare, or automotive, plastic wheels can be customized to meet stringent industry standards and certifications.

- 10. Prototyping and Testing: Customization often involves prototyping and testing to ensure that the wheels meet the desired performance criteria. Manufacturers can work closely with customers to develop and refine custom wheel designs.

Customized plastic wheels are valuable for industries and applications with specific needs, ensuring that the wheels perform optimally and contribute to the overall functionality and efficiency of equipment or systems.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

How does the design of a plastic wheel contribute to its durability and performance?

The design of a plastic wheel plays a significant role in determining its durability and performance. Several key design factors contribute to these attributes:

- 1. Material Selection: The choice of plastic material is crucial. High-quality plastics, such as polyurethane, polypropylene, and nylon, are commonly used for wheel construction. These materials offer excellent durability, impact resistance, and resistance to wear and tear.

- 2. Load Capacity: The design of the wheel must consider the expected load capacity. Reinforcements, such as ribbing or internal structures, can be added to strengthen the wheel and enhance its load-bearing capabilities. Proper load capacity design ensures that the wheel can support the intended weight without deformation or failure.

- 3. Bearing Type: The design of the wheel includes the type of bearing used. Precision bearings, such as ball bearings or roller bearings, reduce friction and ensure smooth rolling. Properly designed bearings enhance the wheel’s performance by reducing resistance and minimizing wear.

- 4. Tread Design: The tread design on the wheel affects its grip, stability, and noise level. Different tread patterns are used for specific applications. For example, smooth treads provide reduced rolling resistance, while treaded designs offer improved traction. The choice of tread design depends on the intended use.

- 5. Hub and Axle Compatibility: The design of the wheel’s hub and axle connection is essential for secure attachment. It should be compatible with the mounting hardware used in the application. A well-designed hub and axle connection ensure stability and prevent wobbling or detachment during use.

- 6. Resilience: The design should consider the wheel’s ability to absorb shocks and impacts. Resilient plastic materials can withstand sudden impacts without cracking or breaking. This is especially important in applications where the wheel may encounter rough terrain or obstacles.

- 7. Temperature Resistance: Depending on the application, plastic wheels may need to withstand a wide range of temperatures. The design should factor in the material’s temperature resistance to ensure that the wheel remains functional in extreme conditions.

- 8. Size and Dimensions: The size and dimensions of the wheel are critical for load distribution and stability. Properly sizing the wheel according to the application’s requirements ensures optimal performance and durability.

- 9. Corrosion Resistance: In some environments, corrosion resistance is essential. The design may incorporate materials or coatings that protect against corrosion, ensuring a longer service life.

- 10. Wheel Mounting: The method of mounting the wheel to the equipment or vehicle is part of the design. It should be secure and reliable to prevent wobbling or detachment during use.

- 11. Weight Distribution: Proper weight distribution across the wheel is important for even wear and reduced stress on the wheel. Design considerations may include the wheel’s shape and load-bearing capacity to ensure even weight distribution.

A well-designed plastic wheel takes into account these factors to maximize its durability and performance. It should be capable of withstanding the demands of its intended application while providing smooth and reliable movement.

editor by Dream 2024-05-08

China Hot selling DCT250 Automatic Transmission parts 6DCT250 Input shaft DCT250 gearbox parts DPS6 shaft input assembly with Great quality

OE NO.: DCT250 DPS6

Size: Standard

Warranty: 12 Months

Vehicle Product: for

Product Quantity: DCT250 DPS6

transmission Variety: Transmission Equipment

Kind: Transmission valve physique

Vehicle Make: Transmission Elements

Product: DCT250 DPS6

Top quality: ideal authentic

Packing: neutral packing

Payment: TT/Western Union/MoneyGram

Packaging Specifics: neutral packing or in accordance to client’s ask for

Port: HangZhou

DPS6 Automatic Transmission

DCT250 DPS6 Automatic Transmission

DCT250 DPS6 Automatic Transmission

DCT250 Automatic Transmission areas 6DCT250 Input shaft DCT250 gearbox components DPS6

Our service

Transmission Learn Repair Package

A130 A131L A132L AW55-50SN JF571E RE0F09A AL4 DPO etc.

Transmission Overhaul Kit

5HP-19 JF011E 81-40LE 03-71LS/72LS AW50-40LE AW50-41LE etc.

Transmission Friction Kit

55-51SN 09G (TF60-SN) RE5R05A 095 096 01M 4T65E 4L60E etc.

Transmission Metal Package

4L40E 5L40E 5L50E 722.6 722.9 AL4 01M 01N AW80-forty and so on.

Transmission Piston Package

09G, Gearbox Worm Reduction Gearmotor Gear Team Equipment Box Reducer Helical Worm Equipment Units Transmission Pace Gearbox 09M, 8 pace gearbox with reverse for Crawler farm transporter mountain climber transporter AL4 DPO, gearboxes gearbox for brush cutter 01M 01N, Precision Planetary Velocity Reducer Gear Box Manufacturer Planetary Gearbox Nema 34 U250E,4R70W CD4E LA4AEL JF405E etc.

Brake Band

722.4 722.320-633 GF4AEL and so on.

Valve Entire body

5HP-19 AL4 01M 9G (TF60-SN)

TCU

0AM 927769D DQ200 TCU Transmission components 0571122B4 DSG7 Velocity

Swich

2529 27 775710009

Transmission CVT Chain

K310 K311 957166 957147 957168 957151 957163 957186 957174 F1C1

Auto Sensor

Oxygen Sensor Abs Sensor Crankshaft Placement Sensor Velocity Sensor etc.

Fuel Injector

06164-POA-000 06164-P8A-A00 23250-28070 35310-2G200 And so on.

Throttle Body

SERA576-01 nissan 06A133062Q 06B133062M etc

Speak to Details

Mobile:-1832571116Skype:xylautopartsWechat:Sally-Wa

What Is a Gearbox?

A gearbox is the mechanical system of an automobile that allows a vehicle to alter equipment effortlessly. This arrangement of gears is extremely intricate, which helps to supply a clean equipment adjust. In this article, we will explore some of the various sorts of gearboxes, including the Epicyclic gearbox, the Coaxial helical gearbox, and the Extruder helical gearing. These are a few of the most frequent types of gearboxes utilised in vehicles.

Gearboxes

Gearboxes help motorists select the proper gear for the problems. A lower gear generates the the very least speed, whilst a increased gear offers the optimum torque. The variety of gears employed in a gearbox varies to meet up with diverse requires on the road and load. Limited gearing provides greatest torque, even though tall gearing delivers higher top speeds. These functions blend to improve the driveability of a motor vehicle. But what is a gearbox?

The gearbox has a slew of components, like the bearings and seals. Between these parts is the gearbox, which is subjected to wear and tear owing to metal-to-metallic get in touch with. As a outcome, gearboxes demand shut checking. Various exams are employed to assess the condition of gears, such as corrosion and wear. Proactive assessments emphasize put on, contamination, and oil situation. However, there are also proactive assessments, this kind of as the ferrous density take a look at and the AN test, which keep track of additive depletion and irregular wear.

The separating power is a key element for the style of a gearbox. The main radial measurement stage need to be oriented to monitor regular forces. The secondary measurement level need to be positioned in the opposite course of rotation from the principal radial measurement point. The separating power generated by a helical equipment set is called tangential power. The major and secondary radial measurement details must be positioned so as to offer data about the two standard and tangential forces.

Manual gearboxes are usually handbook. The driver can control the synchromesh by employing a selector rod. This rod moves the synchromesh to engage the equipment. Reverse gears are not synchromesh because they are utilized only when the motor vehicle is at a standstill. In more mature automobiles, the initial gear frequently lacked synchromesh due to price or absence of torque. Motorists could nevertheless use initial gear with a double-declutch.

Coaxial helical gearbox

The R sequence rigid tooth flank helical gearbox features higher flexibility and very good mixture. They have a vast variety of motor energy and let for good classification of transmission ratios. The R sequence gearbox has a number of rewards, which includes higher efficiency, lengthy provider lifestyle, and reduced vibration. This sequence of gearbox can be blended with a broad range of reducers and variators. Its measurement and high functionality makes it an perfect option for apps that demand highest torque and load transfer.

The principal characteristic of a helical gearbox is that it provides a mounted velocity ratio, even if the heart gaps are not completely established. This is sometimes referred to as the essential rule of gearing. A helical gearbox is similar to paper spur gears in phrases of radial pitch, given that the shafts in the helical gearbox cross at an angle. The heart hole of a helical gearbox is the identical for both the remaining and appropriate-handed counterparts.

The EP Collection is another common product of a Coaxial helical gearbox. This series has substantial torque and a maximum reduction ratio of 25.6:1. It is an ideal option for the plastic market, and CZPT gives an substantial range of versions. Their heart distance ranges from 112 mm to 450 mm. The EP Sequence has a number of versions with distinct center distances. In addition to substantial torque and performance, this gearbox has low noise and vibration, and it is effortless to assemble and disassemble.

Another type of Coaxial helical gearboxes is the planetary gearbox. They have a large performance and electrical power density. As opposed to coaxial helical gearboxes, planetary gearboxes have an axis on the very same route as the output shaft. They are easy to combine into current generate trains. In addition, they are compact and straightforward to combine with present generate trains. For servo programs, they are an additional excellent selection.

Epicyclic gearbox

An epicyclic gearbox is a sort of computerized gearbox employed to drive vehicles. Its primary advantage is its compact style, and it is much more reliable and successful than manual gearboxes. It is comprised of a sunshine gear and two planetary gears, encased in a ring gear named the Annulus. This system is useful for motorists who need to have to shift gears usually, as they will turn into drained if the gears are out of the blue modified.

An epicyclic gearbox is made up of a few various types of gears: ring gear, sunlight equipment, and annular ring equipment. The ring equipment is the outermost gear and has angular-reduce enamel on its internal area. It is used in conjunction with planetary gears to offer large-speed ratios to automobiles. The sunshine gear also reverses the path of the output shaft. This will help reduce transmission mistake.

An epicyclic gearbox employs multiple planets to transfer electricity among the planets. This kind of gearbox is light-weight and characteristics a large energy density. This gearbox has many advantages more than a normal single-stage parallel axis gearbox, including a number of load paths, unequal load sharing, and phased meshing. Moreover, epicyclic gearboxes call for far more complex transmission error optimisation than their counterparts, such as much more than one particular phase.

The goal of epicyclic gearbox research is to supply the least expensive transmission mistake achievable. The method involves an preliminary style and in depth specification. The program is defined by its load spectrum and necessary ratio. Deflections of the elastic mesh are calculated to realize their energy and how a lot power the system can manage. Finally, micro-geometric corrections reduce transmission mistake. These advancements are essential to the total performance of an epicyclic gearbox.

Extruder helical gearing

The helix in an extruder helical gearing is set at an angle, enabling much more interaction with the shaft in the exact same route as it moves. As a outcome, the shaft and the bearing are in constant contact for a prolonged time period of time. Normally, extruder helical gearing is used in apps the place there is minimal pleasure, this sort of as steel, rolling mills, conveyors, and the oil business. The bevel equipment teach also performs a position in these purposes.

The CZPT AEX extruder push gear is exclusively designed for this certain software. The gears are compact and light-weight and supply extraordinary power density and a extended provider existence. These extruder gears are highly reliable, and they can be used in a broad range of applications, including rubber processing, foods production, and recycling vegetation. CZPT offers the two common and custom made gearing for your extruder.

Another benefit of helical gearing is its versatility. Given that the helical gearing enamel are inclined at a specific angle, they can be altered to meet the particular wants of a offered software. These gears also have the advantage of eliminating sounds and shock from straight tooth. Not like other gearing sorts, they are able to accomplish a vast range of loads, from tiny to big. These helical gears are really sturdy and are the very best alternative for substantial-load applications.

In addition to this, uneven helical gears have enhanced flexibility, even though asymmetrical helical gears have lower flexural stiffness. The ratio of enamel to the shaft has a positive influence on the strength of the equipment. In addition, asymmetrical helical gears are less difficult to manufacture. But ahead of you buy your next extruder equipment, make sure you know what you’re obtaining into.

1 speed gearbox

CZPT Team Components produces the 1 velocity gearbox. It has the potential to make automobiles far more efficient and environmentally welcoming. The gear ratio of a car’s drivetrain is critical for achieving highest electricity and speed. Typically, a a single-pace gearbox provides a optimum of 200 hp. But the speed at which a vehicle can get to this electrical power have to be higher to get the complete benefit from the electric motor. So, how can a 1-pace gearbox enhance the pace and torque of a car?

A one-pace gearbox is a mechanical unit utilised to change in between 2nd and third gears. It can contain several gear sets, this sort of as a shared middle gear for switching in between second and third gears. It can also have an intermediate equipment established that signifies a switchable gear in each partial transmissions. The creation also involves a mechanism that makes it less difficult to change gears. The patent claims are thorough underneath. A standard a single-speed gearbox might consist of two elements.

Typically, a one particular-velocity gearbox will have up to 7 ahead gears, with each of these corresponding to a different pace. A one particular-velocity gearbox can have 5 various equipment sets and five various equipment levels. It can have synchronized equipment sets or final-shelf gear sets. In both circumstance, the gears are organized in a way that maximizes their performance. If the gears are placed on opposite sides of a car, the transmission could be a two-speed one particular.

CZPT Transmission specializes in the production of high-speed gearboxes. The firm’s Milltronics HBM110XT gearbox device is the best resource for this task. This device has a massive functioning table and a heavy-duty load capacity, making it a functional selection for several kinds of purposes. There are also a extensive selection of CZPT gearboxes for the automotive business.