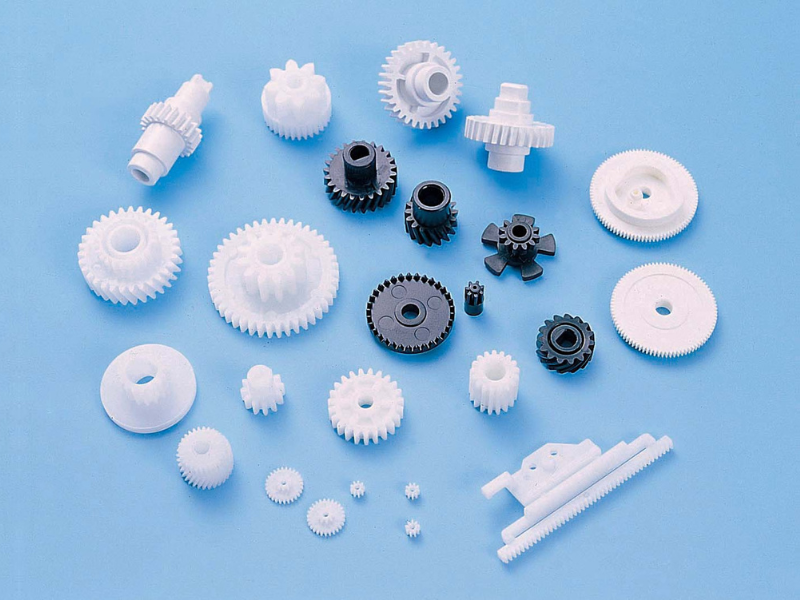

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Our Machine

Product Range

Contact Us /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Plastic |

| Customization: |

Available

|

|

|---|

Can plastic wheels be customized for specific uses or environments?

Yes, plastic wheels can be customized for specific uses or environments to meet unique requirements and applications. Customization options for plastic wheels include:

- 1. Material Selection: Plastic wheels can be manufactured from various types of plastics, each with specific properties. Depending on the application, you can choose the most suitable plastic material to optimize factors like durability, chemical resistance, temperature tolerance, and load-bearing capacity.

- 2. Load Capacity: Custom plastic wheels can be designed with specific load-bearing capabilities in mind. Reinforcements and modifications to the wheel’s structure can be made to increase its load capacity, ensuring it can handle the intended weight.

- 3. Wheel Diameter: The size and diameter of the wheel can be customized to match the terrain and space constraints of the application. Whether you need smaller or larger wheels, customization is possible to ensure a perfect fit.

- 4. Tread Design: The tread pattern on plastic wheels can be tailored to provide optimal traction, stability, and noise reduction for specific environments. Different tread designs are available to suit various surfaces and conditions.

- 5. Bearings: Custom plastic wheels can be equipped with different types of bearings to meet performance requirements. Precision bearings, sealed bearings, or special bearing configurations can be chosen based on the application’s demands.

- 6. Environment-Specific Features: Plastic wheels can be customized with features like corrosion-resistant coatings, anti-static properties, UV resistance, and non-marking materials to accommodate specific environmental conditions.

- 7. Color and Aesthetics: Custom plastic wheels can be produced in various colors and finishes to match the aesthetics of the equipment or environment they are used in. This is common in applications like office furniture and consumer products.

- 8. Mounting Options: Custom wheels can be designed with specific mounting and attachment options to ensure a secure fit with the equipment or vehicle. Custom hubs or axle configurations can be provided.

- 9. Specialized Applications: For highly specialized applications, such as aerospace, healthcare, or automotive, plastic wheels can be customized to meet stringent industry standards and certifications.

- 10. Prototyping and Testing: Customization often involves prototyping and testing to ensure that the wheels meet the desired performance criteria. Manufacturers can work closely with customers to develop and refine custom wheel designs.

Customized plastic wheels are valuable for industries and applications with specific needs, ensuring that the wheels perform optimally and contribute to the overall functionality and efficiency of equipment or systems.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

How does the design of a plastic wheel contribute to its durability and performance?

The design of a plastic wheel plays a significant role in determining its durability and performance. Several key design factors contribute to these attributes:

- 1. Material Selection: The choice of plastic material is crucial. High-quality plastics, such as polyurethane, polypropylene, and nylon, are commonly used for wheel construction. These materials offer excellent durability, impact resistance, and resistance to wear and tear.

- 2. Load Capacity: The design of the wheel must consider the expected load capacity. Reinforcements, such as ribbing or internal structures, can be added to strengthen the wheel and enhance its load-bearing capabilities. Proper load capacity design ensures that the wheel can support the intended weight without deformation or failure.

- 3. Bearing Type: The design of the wheel includes the type of bearing used. Precision bearings, such as ball bearings or roller bearings, reduce friction and ensure smooth rolling. Properly designed bearings enhance the wheel’s performance by reducing resistance and minimizing wear.

- 4. Tread Design: The tread design on the wheel affects its grip, stability, and noise level. Different tread patterns are used for specific applications. For example, smooth treads provide reduced rolling resistance, while treaded designs offer improved traction. The choice of tread design depends on the intended use.

- 5. Hub and Axle Compatibility: The design of the wheel’s hub and axle connection is essential for secure attachment. It should be compatible with the mounting hardware used in the application. A well-designed hub and axle connection ensure stability and prevent wobbling or detachment during use.

- 6. Resilience: The design should consider the wheel’s ability to absorb shocks and impacts. Resilient plastic materials can withstand sudden impacts without cracking or breaking. This is especially important in applications where the wheel may encounter rough terrain or obstacles.

- 7. Temperature Resistance: Depending on the application, plastic wheels may need to withstand a wide range of temperatures. The design should factor in the material’s temperature resistance to ensure that the wheel remains functional in extreme conditions.

- 8. Size and Dimensions: The size and dimensions of the wheel are critical for load distribution and stability. Properly sizing the wheel according to the application’s requirements ensures optimal performance and durability.

- 9. Corrosion Resistance: In some environments, corrosion resistance is essential. The design may incorporate materials or coatings that protect against corrosion, ensuring a longer service life.

- 10. Wheel Mounting: The method of mounting the wheel to the equipment or vehicle is part of the design. It should be secure and reliable to prevent wobbling or detachment during use.

- 11. Weight Distribution: Proper weight distribution across the wheel is important for even wear and reduced stress on the wheel. Design considerations may include the wheel’s shape and load-bearing capacity to ensure even weight distribution.

A well-designed plastic wheel takes into account these factors to maximize its durability and performance. It should be capable of withstanding the demands of its intended application while providing smooth and reliable movement.

editor by Dream 2024-05-08

China Standard Conveyor Belts Roller Transmission Hinged Belt Chip Chain Conveyor Machine injection moulding electrical parts

Product Description

Company Profile

AI-Interroll (ZheJiang ) Automation Equipment Manufacturing Co.,Ltd is a professional manufacturer engaged in spray cooling sterilization machine, PET bottle inverted bottle sterilization machine, bottle lifting conveyor, endless mesh belt conveyor, food grade mesh belt drying machine lines, fruit and vegetable cleaning and sorting machines, packaging machinery, conveying equipment, electronic equipment, automation equipment.

We are a manufacturer integrating research and production, sales and installation.

Aixi equipment: horizontal, running, vertical, turning, screwing, clamping, hanging, flipping, rotating and other conveying lines, chain plates, chain nets, chains, belts, rollers, wind power and other conveying carriers.

Product Description

The flexible chain plate conveyor equipment is an important mechanical foundation with a wide range of applications. It is mainly used in the working conditions of high speed, heavy load, low noise and large center distance. Its transmission performance is better than that of toothed belt transmission, gear transmission and Sub-chain transmission, in order to become 1 of the transmission forms of many industries, can be divided into internal meshing toothed chain, external meshing toothed chain and internal and external composite meshing toothed chain according to the meshing form. The noise of the internal and external composite meshing toothed chain is the lowest. Small and widely used.

The endless mesh belt conveyor is used to transport aquatic products. The whole frame of the modular mesh belt conveyor is made of stainless steel. The conveyor belt adopts the modular plastic mesh belt, which is waterproof and rust-proof.

The endless mesh belt conveyor is a revolution to the traditional belt conveyor. It overcomes the difficulty of maintaining the belt conveyor, and the belt is easily torn, punctured and corroded. It provides customers with a safe, fast and simple maintenance mode of delivery.

Curved belt conveyors are widely used in food, beverage, electric, tobacco and other industries. We can choose a smaller diameter roller to make the corner connection more convenient.

Standard conveyor belt widths are 400, 500, 600, 700, 800, 1000, 1200mm, etc. Other special specifications can also be used according to customer needs. The standard turning radius of the turning belt conveyor is R600, R800, R1000, R1200mm, etc. Other special specifications can also be adopted according to customer needs.

Plastic mesh belt conveyor equipment assembles injection-molded plastic modules into interlocking units with plastic hinge pins that extend across the entire width of the belt. This “brick-laying” method increases the strength of the conveyor belt, and each conveyor belt can be customized and assembled into any desired width and length. The baffles and side panels can also be interlocked with hinge pins and become 1 of the integral parts of the conveyor belt.

Telescopic belt conveyor, it can freely expand and contract in the length direction, and control the length of the conveyor at any time. It can convey materials in 2 directions, and can be used in conjunction with other conveying equipment and material sorting systems to realize automatic production of materials in and out of storage or vehicle loading and unloading, and has been widely used in various industries.

Packaging & Shipping

We can choose the most suitable transportation method according to your needs!

Our Advantages

We have a professional product and equipment research and development team as well as mature technology and rich experience.

We are the direct factory will supply you with high-quality product & quote the most competitive prices.

High effciency is our business philosophy.

FAQ

Are you a trading company or a manufacturer?

We are a manufacturer.

Can you design according to our requirement?

Of course, we can design automation solution according to your technical drawing and requirement. Please tell us your requirement and production process.

How to choose the most suitable Mechanical Equipment?

Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

| After-sales Service: | Warranty |

|---|---|

| Warranty: | One Year |

| Type: | Conveyor |

| Voltage: | 220V |

| Power: | 1.5KW |

| Customized: | Customized |

| Customization: |

Available

| Customized Request |

|---|

Advantages of Injection Moulding

Whether you’re considering an injection molded part for your next project or need to replace an existing one, there are a few factors you should consider. These include design, surface finishes, tooling costs, and material compatibility. Understanding these factors can help you make the right decision. Read on to learn more about the advantages of injection molding and how to get started.

Design factors

One of the most critical design factors for injection molded parts is the wall thickness. The wall thickness affects many key characteristics of the part, from its surface finish to its structural integrity. Proper consideration of this factor can prevent costly delays due to mold issues or mold modifications. To avoid this problem, product designers must carefully consider the functional requirements of the part to determine the minimum and nominal wall thickness. In addition, they must also consider acceptable stress levels, since parts with excessively thin walls may require excessive plastic pressure and may create air traps.

Another factor to consider when designing a part is its ejection and release capabilities. If the part is released from the mold, the tools should be able to slide the plastic out. Injection molds usually have two sides, one of which is ejectable, and another that remains in the mold. In some cases, special features are required to prevent part release, such as a ramp or a gusset. These design features can increase the design flexibility, but they can also increase the cost of the mold.

When designing injection molded parts, the engineering team first determines the key design elements. These elements will make sure the injection process goes as smoothly as possible. This includes factors like wall thickness, rib design, boss design, corner transition, and weld line, among others. The engineering team will then perform a design for manufacturability analysis and, if all is well, can start building and testing the mold.

Material compatibility

Several factors can affect material compatibility of injection molded parts. When molding plastic parts, it is important to choose a material that is compatible with the part’s intended purpose. Many injection molding processes require that the two main plastic materials used are compatible with each other. This is the case in overmolding and two-shot injection molding.

The material you use to make an injection molded part will significantly impact the tolerance of the finished product. This is why material selection is as important as the design of the part. Many types of plastic resins can be used for injection molding. In addition, many of these resins can be modified or strengthened by adding additives, fillers, and stabilizers. This flexibility allows product teams to tailor the material to achieve desired performance characteristics.

One of the most common thermoplastics is polypropylene. It is extremely durable and has good impact strength and moisture resistance. This material is also recyclable and does not react with food.

Tooling costs

One of the largest costs for manufacturing injection molded parts is tooling. For an OEM, tooling costs can range from $15K per part for a simple part to $500K for a mold with complex geometry. Tooling costs vary based on the type of steel used and the production volume of the part.

To get a reasonable estimate, companies should have a final design, preliminary design, and sample part to hand when requesting quotes. The dimensions and complexity of the cavity in a mold are crucial in determining the tooling cost, as are the part tolerances. Part tolerances are based on the area covered by the part and its functions within the mold.

The type of mold you need can also impact your tooling costs. Injection molding machines can accommodate many different kinds of molds. Some molds are made from a single mold, while others require multiple molds. Some molds can be complicated, making them unmanufacturable, which in turn drives up the cost of tooling.

The costs for tooling for injection molding are not well known, but they do add up quickly. Many product development teams tend to consider the cost of the injection molding process in terms of direct materials, machine time, and labor, but that cost model often fails to take into account additional components.

Surface finishes

Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process.

Surface finishes on injection molded parts are often used to mask defects, hide wear and tear, or enhance a product’s appearance. These finishes can also be useful when the product will come in contact with people’s hands. The surface texture you choose will depend on your desired functionality as well as the way you want to use the product. Generally, rougher textures provide better grip while masking minor molding imperfections. However, they can also make a product more difficult to release from the mold. This means that you may have to increase the draft angle of the mold. In order to get the best surface finish, the toolmaker and product designer must collaborate closely early in the design process.

There are several different surface finishes that can be used for injection molded parts. One type is known as the B-grade finish, and is compatible with a wide variety of injection molding plastics. Another type of finish is called a stone polishing process, and is ideal for parts that have no aesthetic value.

Overhangs

The injection moulding industry refers to overhangs on injection molded parts as “undercuts,” and these can lead to design instability. To minimize undercuts, the design must be parallel to the part’s surface. If an undercut is present, a zigzag parting line can be used.

The overhang is typically a few millimeters shorter than the surface of the mold. It is generally made from a lower-cost plastic material than the part’s surface area. The material used for the overhang should have sufficient strength to fulfill its function. An overhang will also help to prevent the piece from deforming or cracking.

Injection molding can create overhangs around the perimeter of a part. Overhangs are not always necessary; they can be added to parts as desired. Adding an overhang, however, will add substantial tooling costs. As a result, it is better to minimize the overall thickness of a design. However, in some cases an overhang can be useful to make the part look more attractive.

For parts with complex geometries, there are a few options for overhangs. Some manufacturers use side-action molds to form more complex shapes.

CNC machining

CNC machining of injection molded parts is a process that helps manufacturers achieve precise surfaces and shapes for their products. This process typically begins with the milling of the tooling, which is typically made of aluminum or steel. This tooling is then placed in a CNC mill. This machine carves the negative of the final plastic part, making it possible to achieve specific surface finishes. The process can be adapted to create a part with a complex structure or special features.

CNC machining allows the manufacturer to produce high-performance parts. This is possible because MIM parts do not experience induced stresses or internal pressure during the manufacturing process. Furthermore, the parts produced by MIM are more durable than CNC parts. Despite their advantages, CNC machining has its limitations, especially when it comes to design freedom and intricacy. This factor is largely dependent on the software used by the manufacturer or designer.

One drawback of CNC machining is its higher cost. Compared to injection molding, CNC machining is more expensive per part. The reason is that the initial mold cost is relatively high and is spread over a large number of parts. Once the injection molding process has been completed, the cost of the parts produced by this process becomes more competitive with those produced by machined parts. However, the cost gap increases with the volume of parts produced. This cost crossover generally occurs in quantities of at least 100 parts and can reach a maximum of 5000 parts.

Production volume

The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making.

The production volume of injection molded parts varies depending on the material being used. Large volumes of parts are expensive to produce, while small quantities can be produced for low cost. Injection molding requires a precise mold, which is CNC-machined from tool steel or aluminum. The mold has a negative of the part that is injected, a runner system, and internal water cooling channels to aid in cooling the part. Recent advances in 3D printing materials have made it possible to produce molds for low-volume injection molding. Previously, this was not financially viable due to the high cost of traditional mold making.

A mold is used to produce plastic parts. The molding process is very fast, with each cycle taking anywhere from 30 seconds to 90 seconds. After a part is molded, it is removed from the mold and placed on a holding container or conveyor belt. Injection molded parts are generally ready for use right away and require minimal post-processing. Injection molded parts have a similar design to a photograph, since the geometry is directly transferred to the part’s surface texture.

When selecting a plastic mold, it is important to determine the volume that the part will be produced at. If the volume is low, softer plastics may be used. However, as the part is molded over, its performance characteristics may degrade. In low-volume production, it is important to consider the overall complexity of the part. This includes the part’s draft, wall thickness, and surface finish.

editor by CX 2023-11-21

China best Transmission chain gearbox chain belt 901083 901047 901066 901068 901074 901072 901029 901063 with Free Design Custom

OE NO.: 957147

Design: TEANA (L33Z), TEANA (J31), X-Path (T31), TEANA GONGJUE (J33), GTM gearbox rotary mower gearbox agricultural farm gearbox TEANA (J32Z), X-Trail (T32)

Year: 2014-, 2004-2008, 2008-, 90 diploma bevel transmission equipment box gearbox 2014-, 2008-2014, 2013-

Auto Fitment: NISSAN (XIHU (WEST LAKE) DIS.FENG)

Guarantee: 12months

Vehicle Product: TEANA

Size: twenty five*20*ten 2KG

Solution name: Chain

Certification: IOS

Specification itemvalueOE NO.957147Warranty12monthsPlace of OriginChinaBrand NameAUTOWERKZCertificationIOSCar ModelTEANASize25*20*10 2KGProduct nameChain Packing & Shipping HangZhou CZPT Trading Co. Ltd. specializes in the trading of auto transmission parts. With over ten years of encounter, CZPT manufacturer Chinese maker 8-16 arcmin PRF120 equipment planetary reducer gearbox for servo motor the firm observes stringent good quality control to make sure that all of the merchandise are of the optimum high quality. Products we supply include overhaul package, friction plate, solenoid, piston, Planetary Gearbox Gear Velocity Increaser valve body and a comprehensive transmission set. For more enquiries, you should contact us at 13822234786 and we will get back to you in the shortest time feasible. FAQ

What Is a Gearbox?

A gearbox is the mechanical method of an auto that enables a vehicle to adjust equipment efficiently. This arrangement of gears is extremely sophisticated, which will help to offer a easy equipment change. In this write-up, we will check out some of the distinct varieties of gearboxes, including the Epicyclic gearbox, the Coaxial helical gearbox, and the Extruder helical gearing. These are three of the most typical types of gearboxes used in automobiles.

Gearboxes

Gearboxes aid drivers choose the appropriate gear for the problems. A decrease equipment produces the least pace, while a increased equipment offers the maximum torque. The number of gears employed in a gearbox varies to fulfill different needs on the road and load. Limited gearing offers maximum torque, while tall gearing delivers larger top speeds. These features mix to boost the driveability of a vehicle. But what is a gearbox?

The gearbox has a slew of elements, including the bearings and seals. Amid these parts is the gearbox, which is subjected to put on and tear because of to metallic-to-steel make contact with. As a result, gearboxes need close checking. Various assessments are employed to evaluate the problem of gears, such as corrosion and wear. Proactive exams emphasize use, contamination, and oil issue. Even so, there are also proactive checks, this sort of as the ferrous density test and the AN test, which check additive depletion and irregular put on.

The separating power is a crucial issue for the style of a gearbox. The primary radial measurement position ought to be oriented to monitor regular forces. The secondary measurement point must be located in the reverse direction of rotation from the major radial measurement point. The separating drive produced by a helical gear set is named tangential power. The primary and secondary radial measurement factors should be positioned so as to provide details about the two regular and tangential forces.

Guide gearboxes are frequently guide. The driver can manage the synchromesh by employing a selector rod. This rod moves the synchromesh to engage the gear. Reverse gears are not synchromesh due to the fact they are utilised only when the automobile is at a standstill. In more mature autos, the first equipment typically lacked synchromesh due to value or absence of torque. Drivers could still use first gear with a double-declutch.

Coaxial helical gearbox

The R series rigid tooth flank helical gearbox characteristics large flexibility and great mixture. They have a vast variety of motor electricity and allow for fine classification of transmission ratios. The R sequence gearbox has a number of advantages, which includes substantial efficiency, extended provider daily life, and reduced vibration. This sequence of gearbox can be blended with a wide selection of reducers and variators. Its dimension and substantial overall performance makes it an ideal option for purposes that require greatest torque and load transfer.

The principal characteristic of a helical gearbox is that it provides a mounted velocity ratio, even if the heart gaps are not completely set. This is often referred to as the fundamental rule of gearing. A helical gearbox is related to paper spur gears in terms of radial pitch, given that the shafts in the helical gearbox cross at an angle. The centre hole of a helical gearbox is the exact same for both the remaining and right-handed counterparts.

The EP Collection is an additional popular design of a Coaxial helical gearbox. This collection has substantial torque and a highest reduction ratio of twenty five.6:1. It is an perfect option for the plastic market, and CZPT delivers an extensive range of models. Their middle length ranges from 112 mm to 450 mm. The EP Collection has numerous models with different centre distances. In addition to high torque and efficiency, this gearbox has low noise and vibration, and it is simple to assemble and disassemble.

Yet another sort of Coaxial helical gearboxes is the planetary gearbox. They have a higher efficiency and power density. As opposed to coaxial helical gearboxes, planetary gearboxes have an axis on the identical direction as the output shaft. They are straightforward to integrate into existing generate trains. In addition, they are compact and easy to integrate with existing drive trains. For servo programs, they are one more wonderful option.

Epicyclic gearbox

An epicyclic gearbox is a variety of computerized gearbox utilized to generate automobiles. Its major edge is its compact design and style, and it is far more dependable and effective than guide gearboxes. It is comprised of a solar equipment and two planetary gears, encased in a ring gear named the Annulus. This system is useful for motorists who need to have to change gears regularly, as they will turn into tired if the gears are out of the blue changed.

An epicyclic gearbox consists of 3 various varieties of gears: ring equipment, sunshine equipment, and annular ring gear. The ring gear is the outermost equipment and has angular-minimize tooth on its inner area. It is employed in conjunction with planetary gears to provide high-speed ratios to autos. The sunshine equipment also reverses the direction of the output shaft. This assists decrease transmission error.

An epicyclic gearbox uses a number of planets to transfer power between the planets. This kind of gearbox is light-weight and functions a higher power density. This gearbox has a number of advantages over a common one-phase parallel axis gearbox, including multiple load paths, unequal load sharing, and phased meshing. In addition, epicyclic gearboxes require a lot more sophisticated transmission mistake optimisation than their counterparts, like far more than 1 phase.

The aim of epicyclic gearbox investigation is to offer the most affordable transmission mistake feasible. The procedure involves an original style and thorough specification. The program is outlined by its load spectrum and needed ratio. Deflections of the elastic mesh are calculated to realize their toughness and how a lot strength the method can deal with. Finally, micro-geometric corrections reduce transmission mistake. These improvements are essential to the overall effectiveness of an epicyclic gearbox.

Extruder helical gearing

The helix in an extruder helical gearing is set at an angle, enabling a lot more conversation with the shaft in the same route as it moves. As a consequence, the shaft and the bearing are in continual contact for a lengthy period of time. Normally, extruder helical gearing is utilized in programs in which there is reduced enjoyment, this kind of as metal, rolling mills, conveyors, and the oil industry. The bevel equipment teach also performs a role in these apps.

The CZPT AEX extruder push equipment is specifically produced for this particular application. The gears are compact and light-weight and offer outstanding power density and a extended services existence. These extruder gears are hugely reputable, and they can be utilized in a broad assortment of applications, such as rubber processing, foodstuff creation, and recycling crops. CZPT gives the two standard and personalized gearing for your extruder.

One more edge of helical gearing is its flexibility. Since the helical gearing teeth are inclined at a specific angle, they can be modified to meet the certain requirements of a presented application. These gears also have the gain of reducing noise and shock from straight tooth. Not like other gearing varieties, they are ready to attain a broad assortment of masses, from modest to big. These helical gears are really tough and are the best option for substantial-load apps.

In addition to this, uneven helical gears have increased flexibility, whilst asymmetrical helical gears have reduced flexural stiffness. The ratio of enamel to the shaft has a positive impact on the energy of the gear. Furthermore, asymmetrical helical gears are simpler to manufacture. But just before you obtain your following extruder equipment, make positive you know what you happen to be receiving into.

one velocity gearbox

CZPT Team Elements creates the one velocity gearbox. It has the potential to make autos more effective and environmentally helpful. The gear ratio of a car’s drivetrain is critical for achieving optimum energy and pace. Normally, a one particular-speed gearbox delivers a maximum of 200 hp. But the speed at which a car can achieve this electricity should be high to get the complete benefit from the electric powered motor. So, how can a one particular-pace gearbox improve the pace and torque of a car?

A one particular-speed gearbox is a mechanical device used to change among second and third gears. It can include multiple gear sets, this sort of as a shared middle equipment for switching in between next and third gears. It can also have an intermediate gear set that signifies a switchable gear in each partial transmissions. The creation also contains a system that can make it less difficult to adjust gears. The patent claims are in depth underneath. A common 1-velocity gearbox might incorporate two parts.

Generally, a one particular-velocity gearbox will have up to 7 ahead gears, with each of these corresponding to a different speed. A a single-velocity gearbox can have five distinct equipment sets and 5 diverse equipment levels. It can have synchronized gear sets or last-shelf gear sets. In possibly circumstance, the gears are organized in a way that maximizes their effectiveness. If the gears are positioned on opposite sides of a auto, the transmission might be a two-pace one particular.

CZPT Transmission specializes in the production of large-velocity gearboxes. The firm’s Milltronics HBM110XT gearbox machine is the ideal resource for this job. This device has a large functioning table and a large-obligation load capability, making it a versatile option for a lot of varieties of purposes. There are also a extensive variety of CZPT gearboxes for the automotive industry.