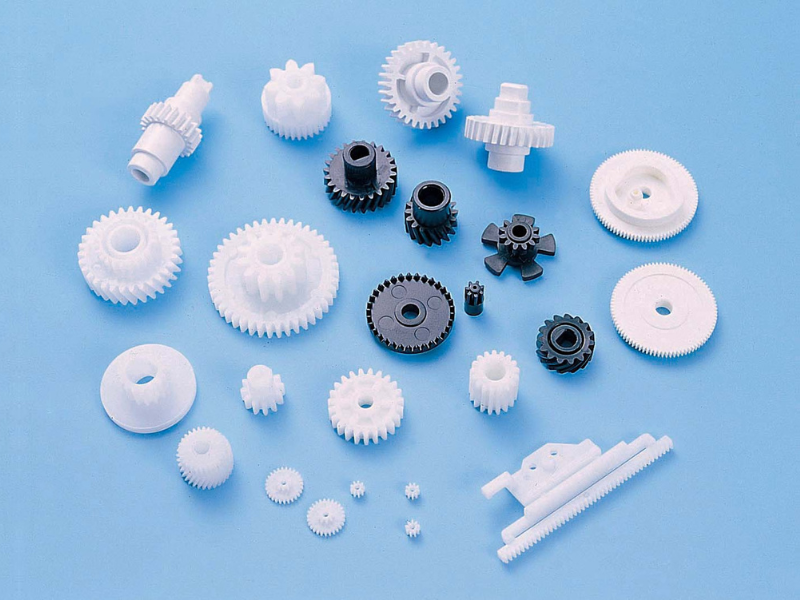

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Our Machine

Product Range

Contact Us /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Plastic |

| Customization: |

Available

|

|

|---|

Can plastic wheels be customized for specific uses or environments?

Yes, plastic wheels can be customized for specific uses or environments to meet unique requirements and applications. Customization options for plastic wheels include:

- 1. Material Selection: Plastic wheels can be manufactured from various types of plastics, each with specific properties. Depending on the application, you can choose the most suitable plastic material to optimize factors like durability, chemical resistance, temperature tolerance, and load-bearing capacity.

- 2. Load Capacity: Custom plastic wheels can be designed with specific load-bearing capabilities in mind. Reinforcements and modifications to the wheel’s structure can be made to increase its load capacity, ensuring it can handle the intended weight.

- 3. Wheel Diameter: The size and diameter of the wheel can be customized to match the terrain and space constraints of the application. Whether you need smaller or larger wheels, customization is possible to ensure a perfect fit.

- 4. Tread Design: The tread pattern on plastic wheels can be tailored to provide optimal traction, stability, and noise reduction for specific environments. Different tread designs are available to suit various surfaces and conditions.

- 5. Bearings: Custom plastic wheels can be equipped with different types of bearings to meet performance requirements. Precision bearings, sealed bearings, or special bearing configurations can be chosen based on the application’s demands.

- 6. Environment-Specific Features: Plastic wheels can be customized with features like corrosion-resistant coatings, anti-static properties, UV resistance, and non-marking materials to accommodate specific environmental conditions.

- 7. Color and Aesthetics: Custom plastic wheels can be produced in various colors and finishes to match the aesthetics of the equipment or environment they are used in. This is common in applications like office furniture and consumer products.

- 8. Mounting Options: Custom wheels can be designed with specific mounting and attachment options to ensure a secure fit with the equipment or vehicle. Custom hubs or axle configurations can be provided.

- 9. Specialized Applications: For highly specialized applications, such as aerospace, healthcare, or automotive, plastic wheels can be customized to meet stringent industry standards and certifications.

- 10. Prototyping and Testing: Customization often involves prototyping and testing to ensure that the wheels meet the desired performance criteria. Manufacturers can work closely with customers to develop and refine custom wheel designs.

Customized plastic wheels are valuable for industries and applications with specific needs, ensuring that the wheels perform optimally and contribute to the overall functionality and efficiency of equipment or systems.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

How does the design of a plastic wheel contribute to its durability and performance?

The design of a plastic wheel plays a significant role in determining its durability and performance. Several key design factors contribute to these attributes:

- 1. Material Selection: The choice of plastic material is crucial. High-quality plastics, such as polyurethane, polypropylene, and nylon, are commonly used for wheel construction. These materials offer excellent durability, impact resistance, and resistance to wear and tear.

- 2. Load Capacity: The design of the wheel must consider the expected load capacity. Reinforcements, such as ribbing or internal structures, can be added to strengthen the wheel and enhance its load-bearing capabilities. Proper load capacity design ensures that the wheel can support the intended weight without deformation or failure.

- 3. Bearing Type: The design of the wheel includes the type of bearing used. Precision bearings, such as ball bearings or roller bearings, reduce friction and ensure smooth rolling. Properly designed bearings enhance the wheel’s performance by reducing resistance and minimizing wear.

- 4. Tread Design: The tread design on the wheel affects its grip, stability, and noise level. Different tread patterns are used for specific applications. For example, smooth treads provide reduced rolling resistance, while treaded designs offer improved traction. The choice of tread design depends on the intended use.

- 5. Hub and Axle Compatibility: The design of the wheel’s hub and axle connection is essential for secure attachment. It should be compatible with the mounting hardware used in the application. A well-designed hub and axle connection ensure stability and prevent wobbling or detachment during use.

- 6. Resilience: The design should consider the wheel’s ability to absorb shocks and impacts. Resilient plastic materials can withstand sudden impacts without cracking or breaking. This is especially important in applications where the wheel may encounter rough terrain or obstacles.

- 7. Temperature Resistance: Depending on the application, plastic wheels may need to withstand a wide range of temperatures. The design should factor in the material’s temperature resistance to ensure that the wheel remains functional in extreme conditions.

- 8. Size and Dimensions: The size and dimensions of the wheel are critical for load distribution and stability. Properly sizing the wheel according to the application’s requirements ensures optimal performance and durability.

- 9. Corrosion Resistance: In some environments, corrosion resistance is essential. The design may incorporate materials or coatings that protect against corrosion, ensuring a longer service life.

- 10. Wheel Mounting: The method of mounting the wheel to the equipment or vehicle is part of the design. It should be secure and reliable to prevent wobbling or detachment during use.

- 11. Weight Distribution: Proper weight distribution across the wheel is important for even wear and reduced stress on the wheel. Design considerations may include the wheel’s shape and load-bearing capacity to ensure even weight distribution.

A well-designed plastic wheel takes into account these factors to maximize its durability and performance. It should be capable of withstanding the demands of its intended application while providing smooth and reliable movement.

editor by Dream 2024-05-08

China Hot selling wholesale metal Car Key chain Six Speed Gear Shift key ring Gearbox Key chains wholesaler

Model Quantity: JK-52

Type: Coin Holder Keychain

Substance: Metal

Metal Variety: Iron

Printing: UV printing

Print Strategy: 1 coloration, 2 shade, 4 colour, 5 coloration, 6 coloration

Identify: Metal equipment key chain

Color: gold , black, crimson . silver and blue

Keychain Sort: key ring keychain

Form: Tailored Shape

MOQ: 100pcs

Transport strategy: DHL Fedex UPS TNT Aramex

OEM & ODM: support

PAYMENT: T/T , Western Union and Paypal

Packaging Particulars: common bundle

wholesale steel Car Crucial chain 6 Speed Gear Change crucial ring Gearbox Essential chains

SpecificationsItem

inexpensive price equipment essential accessories Keychain

Substance

Steel important ring chain

Attachment

Metal ring, Metallic chain + ring, Ball chain, or other customized accent

Bundle

specific opp bag or personalized package deal

Usage

Memento, Colletible, Commemorative, Promotion reward, Business present, AL4 DPO Computerized Transmission System Gearbox 1.6L 2.0L For Peugeot 306 307 308 206 207 for Citroen C2 C3 C4 C5 for Renault Clio Adertising gift, and so forth.

Feature

Totally free artwork

Quick sample & manufacturing guide time and competitive value

Direct Time

Sample Time:3-5 days

Mass Production Time:5-8 times

Payment

PayPal, Western Union, T/T, Credit rating Card / Safe Payment

Shipping

UPS/DHL/FedEx/TNT/EMS or Ali convey

OEM/ODM

Customise print

Our Services

Delivery Coverage:1- Regularly, we shipped by means of Fedex/Dhl/UPS..Specific way.(2-7 functioning days arrival), appropriate for modest order.2- Sea shipping way, (twenty five-forty times arrival), reduced value, port to port, typically for big amount get.Personalized/OEM:Custom made Brand,colour,design and style is okay.Sample Coverage:1- Typically we offer random sample for free of charge but with your sample shipping and delivery freight cost compensated.2- We offer you 1-2 pcs every sample randomly, if for more pcs, Professional planetary gearbox pace increaser Max input speed n18 rpm ten thousand we will consider deliver to you, if not and you must

ask for more pcs, we will charge very same sample costs for make a lot more pcs samples to you.Effortless buy procedure:Make sure you kindly confirm us about merchandise title, photos, colours and quantity ahead of you buying.

Packaging & ShippingPackage: Normal package deal .

Shipping techniques: DHL, EMS OR UPS, the merchandise will be delivered in 5-7 doing work days.

Certifications

Business Data

FAQQone: Do you testing the items just before shipment?

A: we examined each prodcuts top quality just before send out out .

Qtwo: What is your payment techniques ?

A: T/T,Paypal,West Union and Alibaba trade Assurance.

Qthree:What is the direct time?Sample get is offered?

A: lead time : 7-15 operating times. We don’t have MOQ, Sample order is ok.

Qfour:Can you make in accordance to the samples?A: Sure, we can create by your samples or technological drawings design. We can also construct the molds.

Q5. What is your phrases of packing?A: Normally, we pack our goods in neutral white bins and brown cartons. Also if you have lawfully registered patent, Progress CZPT Maritime Gearbox 120C 135A three hundred HC400 we can pack the merchandise in your branded bins.

Types of Gearboxes

There are a number of types of gearboxes. Some are recognized as helical gear reducers, even though other individuals are called planetary gearboxes. The post also discusses Constantly Variable Transmission (CVT) and helical gear reducer. If you are intrigued in getting a new gearbox, make positive to read our content articles on these distinct types. If you are puzzled, take into account looking through our articles on planetary gearboxes and helical equipment reducers.

planetary gearbox

The planetary gearbox has a number of positive aspects. Its compact style and light-weight weight allows it to transmit higher torques even though remaining quiet. The gears are linked to 1 one more via a carrier, which is generally fastened and helps transmit torques to the output shaft. Its planetary structure arrangement also minimizes backlash and gives large rigidity, which is important for fast commence and cease cycles and rotational route modify. Based on the design and style and overall performance wanted, planetary gearboxes are categorized into 3 primary varieties:

The sort of planetary gears utilized in a provided software decides the all round price of the unit. Producers supply a range of charges, and they can help you determine which gearbox is correct for your requirements. You should also question a producer for the price of a planetary gearbox. By inquiring about cost and specs, you can stay away from losing money and time on a planetary gearbox that does not complete up to its potential.

A planetary gearbox is probably set up in your new car’s automatic transmission. For a lot more information, seek advice from your owner’s guide or get in touch with the dealer’s provider division. This variety of gearbox is far more complex than other varieties of gearboxes, so if you will not know a lot about them, do an world wide web look for for “planetary gearbox.”

The tooth of a planetary gearbox are fashioned by the stepping motion of two gears: the solar equipment and the inner ring. The sunshine gear is the enter, while the planetary gears rotate around the solar equipment. Their ratio depends on the number of tooth and the area among the planets. If you have a 24 tooth solar gear, the planetary gears’ ratio will be -3/2. The sunlight equipment is also attached to the axle.

An additional benefit of a planetary equipment system is that it can make higher torques. The load is shared amid a number of planet gears. This helps make the gears far more resilient to damage. A planetary gearbox can be as substantial as 332,000 Nm, and can be utilized in autos and industrial apps requiring medium to substantial torque. A planetary gear system is a fantastic alternative to a classic transmission. So, how does it operate?

helical gearbox

The primary big difference among the helical gearbox and the spur equipment is the centre distance among the tooth. The helical gearbox has a greater pitch circle than the spur equipment and hence calls for a radial module. In addition, the two varieties of gears can only be manufactured with the exact same tooth-cutting instrument as the spur equipment. However, the helical gearbox is far more efficient in conditions of generation charges.

The helical gearbox is a low-electrical power usage, compact variety of gearbox that is utilised for a wide assortment of industrial programs. They are highly sturdy and withstand higher loads with utmost effectiveness. The helical gearbox can be produced in forged steel and iron for tiny and medium models. This sort of gearbox is also generally used for crushers, conveyors, coolers, and other applications that require minimal power.

The helical gear has many advantages over the spur gear. It creates significantly less noise. It has less friction and is less most likely to wear out. It is also quieter than spur gears. This is because a number of enamel are in mesh. Because the enamel are in mesh, the load is dispersed over a more substantial region, ensuing in a smoother changeover between gears. The reduction in sounds and vibration lowers the danger of damaging the gear.

The helical gear’s axial excitation power is attained utilizing a linearized equation of movement in the rotational route. The damping coefficient of the equation is .07. The helical equipment is made up of a steel shaft with a diameter of twenty mm and a 5 mm thick aluminum plate. The stiffness of the bearing is 6.84 x 107 N/m. The damping power of the plate is 2,040 kg/m2/s.

The worm gearbox has a far better effectiveness ratio than the helical one, but it is considerably less successful in reduced-ratio applications. In general, worm gearboxes are much more productive than helical gearboxes, though there are some exceptions to this rule. A helical gearbox is better for purposes that demand substantial torque. It could also be much more affordable in the lengthy run. If you are taking into consideration a helical gearbox, consider the benefits it has in excess of worm gearboxes.

helical equipment reducer

A helical equipment reducer for a machine’s gearbox is an integral element of the drive system. This unit amplifies torque and controls velocity and, for that reason, compliments the motor by rotating slower than the engine’s input shaft. A helical equipment reducer is a compact gearbox element that is utilized in industrial purposes. A assortment of dimensions is offered to fit a variety of equipment configurations. The adhering to sections will discuss some of the different sorts offered.

Made by authorities and engineers, a helical equipment reducer is a remarkably small and light equipment that satisfies the requirements of many equipment purposes. It features a massive transmission torque, a lower commencing and working pace, and a fine classification of transmission ratios. A helical gear reducer is lightweight and simply linked to other gears, and it functions a large specialized articles.

In purchase to steer clear of mistakes and poor overall performance, standard servicing is a should. The proper lubrication of the gear reducer can reduce failures, problems, and inadequate performance. Each equipment reducer manufacturer sells a suited lubricant, which have to match the properties of the machine’s generate mechanism. It is also a good idea to check the lubrication routinely to keep away from any deterioration of the unit’s functionality.

Whilst the worm gearbox may be much better for applications the place torque is substantial, the helical equipment reducer provides higher performance at reduced value. Though worm gearboxes could be less costly to begin with, they are much less powerful at larger ratios. Even if the worm equipment is far more expensive to buy, it still delivers 94% effectiveness, which can make it far more expense-effective. There are some important advantages to equally varieties of gearboxes.

The major edge of a helical equipment reducer more than a spur gear is its smoother procedure. Not like spur gears, which have tooth that are straight, helical gears have angled tooth that progressively interact with every single other. This will help make certain that the gear does not grind or make excessive sounds when it turns. Moreover, they are much less typically utilised in automation and precision equipment. They are often utilised in industrial applications.

Repeatedly variable transmission

A Continuously Variable Transmission (CVT) is an automatic transmission that can operate by way of a huge amount of gears. Unlike a regular automatic transmission, it can run at any pace, even at a lower rev. The CVT is also able of running at infinitely minimal gears. Its simple operate is to give distinct torque ratios to the motor. In addition to providing power, CVTs have other benefits.

1 of the significant benefits of a CVT is its simplicity. Its simplicity interprets into less moving elements, which indicates less servicing. The CVT’s simplicity also means that it can take care of a wide range of diverse types of road conditions and driving designs. In addition to currently being a fantastic substitute to a traditional automated transmission, CVTs can be utilised on numerous other kinds of vehicles, like tractors, snowmobiles, motor scooters, and power tools.

A CVT is a lot smoother than a traditional computerized transmission. It never has to hunt for a equipment. It also responds properly to throttle inputs and speed alterations. Both of these systems are available on several present day cars, like the Nissan Rogue and Mazda CX-5. It is critical to note that every of these transmissions has its execs and downsides. So, if you’re searching for a automobile with a CVT, make certain to read through the critiques. They will aid you decide which transmission is correct for you.

Another benefit of a CVT is its gasoline efficiency. Numerous cars now characteristic CVTs, and they are turning out to be more and more well-known with automakers. In addition to gas performance, most vehicles with CVTs also have a smoother journey. There’s no a lot more unexpected downshifts or gear hunting. This can make driving a good deal simpler. And, the additional rewards of smoother driving make CVTs the excellent option for numerous motorists.

Even though a CVT is more widespread among Japanese automobile makers, you will uncover CVTs on European car models as effectively. The Mercedes-Benz A-Class, B-Class, and Megane are some illustrations of autos that use this technology. Before generating a choice, take into account the dependability of the product in concern. Client Reviews is a great resource for this. It also gives a background of use and trustworthiness for each variety of auto, such as the Honda Accord.