Product Description

Product Description

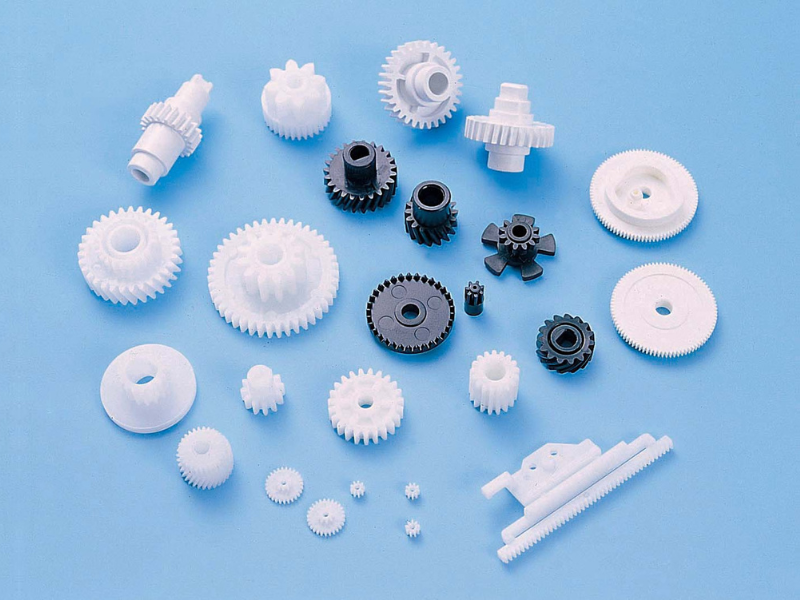

Machine Nylon Drive Transmission Injection Plastic Toothed Cylindrical Straight Spur Gear Cog-Wheel

| Item | Customized Injection and machining gears | |

| Process | Injection molding,CNC machining, | |

| material | Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that commonly use plastic wheels?

Plastic wheels are used in a wide range of products and machinery across various industries due to their versatility and unique qualities. Here are examples of products and machinery that commonly use plastic wheels:

- 1. Office Furniture: Office chairs often feature plastic caster wheels for smooth and quiet movement on office floors.

- 2. Material Handling Equipment: Hand trucks, dollies, and carts used in warehouses and distribution centers frequently use plastic wheels to transport goods efficiently.

- 3. Lawn and Garden Equipment: Lawnmowers, garden carts, and wheelbarrows are equipped with plastic wheels for easy maneuverability on lawns and uneven terrain.

- 4. Retail and Shopping Carts: Shopping carts in supermarkets and retail stores typically have plastic wheels for easy navigation through aisles.

- 5. Medical Equipment: Hospital beds, medical carts, and mobility aids often incorporate plastic wheels, as they are easy to clean and resist corrosion.

- 6. Aerospace Ground Support: Ground support equipment at airports, including baggage carts and maintenance vehicles, may use plastic wheels for their lightweight properties.

- 7. Food and Beverage Handling: Food service equipment, such as serving trolleys and food processing machinery, often feature plastic wheels due to their resistance to moisture and corrosion.

- 8. Recreational Vehicles (RVs): RV leveling jacks and stabilizers utilize plastic wheels to provide stability and ease of adjustment when parked.

- 9. DIY and Home Improvement Tools: Hand trucks, utility carts, and toolboxes used for DIY and home improvement projects may have plastic wheels for ease of movement.

- 10. Industrial Machinery: Some industrial machines and equipment incorporate plastic wheels to facilitate movement and protect factory floors.

- 11. Conveyor Systems: Conveyor systems in manufacturing and logistics often use plastic wheels to support the movement of goods along production lines.

- 12. Skateboards and Skateboarding Equipment: Skateboard wheels are typically made of plastic, offering various sizes and hardness levels to suit different riding styles.

- 13. Boat Trailer Rollers: Rollers on boat trailers are commonly made of plastic, as they resist corrosion when exposed to water and provide smooth boat launching and retrieval.

- 14. Gate Hardware: Some gate wheels and sliding door systems feature plastic wheels for smooth operation and reduced noise.

These examples demonstrate the widespread use of plastic wheels in diverse applications, emphasizing their adaptability and suitability for various industries and products.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

What are the different types and sizes of plastic wheels available in the market?

The market offers a variety of plastic wheels, each designed for specific applications and available in various sizes. Here are different types and sizes of plastic wheels commonly available:

- 1. Caster Wheels: Caster wheels are used for mobility and swiveling in a wide range of applications. They come in sizes ranging from small, furniture casters to large, heavy-duty industrial casters.

- 2. Hand Truck Wheels: These wheels are commonly used on hand trucks and dollies for moving heavy loads. They are available in sizes such as 8-inch, 10-inch, and 12-inch diameters.

- 3. Trolley Wheels: Trolley wheels are used on material handling carts and trolleys. They come in various sizes, including 4-inch, 5-inch, and 6-inch diameters.

- 4. Lawnmower Wheels: These wheels are designed for lawnmowers and other outdoor equipment. They are available in sizes like 8-inch, 10-inch, and 12-inch diameters.

- 5. Office Chair Casters: Office chair casters come in different sizes to fit various chair bases. Common sizes include 2-inch, 2.5-inch, and 3-inch diameters.

- 6. Heavy-Duty Industrial Wheels: These wheels are used in industrial and manufacturing settings. They are available in larger sizes, such as 6 inches, 8 inches, and even up to 12 inches or more in diameter.

- 7. Skateboard Wheels: Plastic skateboard wheels come in various sizes, typically ranging from 50mm to 60mm in diameter, with different hardness levels for different riding styles.

- 8. Conveyor Wheels: Conveyor wheels are used in material handling and conveyor systems. They come in sizes suitable for specific conveyor designs and loads.

- 9. V-Groove Wheels: V-groove wheels are designed for use on tracks or grooves. They come in sizes suitable for different track profiles and load capacities.

- 10. Trailer Jack Wheels: Trailer jack wheels are used for trailer jacks and stabilizers. They come in sizes such as 6-inch, 8-inch, and 10-inch diameters.

- 11. Light-Duty Wheels: These wheels are used in various light-duty applications, such as small carts and furniture. They are available in sizes ranging from 1 inch to 6 inches in diameter.

- 12. Specialized Wheels: Some plastic wheels are designed for specific applications, such as luggage wheels, boat trailer rollers, and gate wheels. Their sizes vary depending on the intended use.

The availability of plastic wheels in different types and sizes allows them to cater to a wide range of industries and applications. When selecting a plastic wheel, it’s essential to consider factors like load capacity, wheel diameter, tread design, and material to ensure it meets the requirements of the specific use case.

editor by Dream 2024-05-17

China wholesaler Plastic Precision Transmission Drive Reduction Cylindrical Involute Duplicate Helical Spur Gear Cog-Wheel

Product Description

Product Description

Plastic Precision Transmission Drive reduction cylindrical Involute Duplicate Helical Spur Gear Cog-Wheel

| Item | Customized Injection and machining gears | |

| Process | Injection molding,CNC machining, | |

| material | Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that commonly use plastic wheels?

Plastic wheels are used in a wide range of products and machinery across various industries due to their versatility and unique qualities. Here are examples of products and machinery that commonly use plastic wheels:

- 1. Office Furniture: Office chairs often feature plastic caster wheels for smooth and quiet movement on office floors.

- 2. Material Handling Equipment: Hand trucks, dollies, and carts used in warehouses and distribution centers frequently use plastic wheels to transport goods efficiently.

- 3. Lawn and Garden Equipment: Lawnmowers, garden carts, and wheelbarrows are equipped with plastic wheels for easy maneuverability on lawns and uneven terrain.

- 4. Retail and Shopping Carts: Shopping carts in supermarkets and retail stores typically have plastic wheels for easy navigation through aisles.

- 5. Medical Equipment: Hospital beds, medical carts, and mobility aids often incorporate plastic wheels, as they are easy to clean and resist corrosion.

- 6. Aerospace Ground Support: Ground support equipment at airports, including baggage carts and maintenance vehicles, may use plastic wheels for their lightweight properties.

- 7. Food and Beverage Handling: Food service equipment, such as serving trolleys and food processing machinery, often feature plastic wheels due to their resistance to moisture and corrosion.

- 8. Recreational Vehicles (RVs): RV leveling jacks and stabilizers utilize plastic wheels to provide stability and ease of adjustment when parked.

- 9. DIY and Home Improvement Tools: Hand trucks, utility carts, and toolboxes used for DIY and home improvement projects may have plastic wheels for ease of movement.

- 10. Industrial Machinery: Some industrial machines and equipment incorporate plastic wheels to facilitate movement and protect factory floors.

- 11. Conveyor Systems: Conveyor systems in manufacturing and logistics often use plastic wheels to support the movement of goods along production lines.

- 12. Skateboards and Skateboarding Equipment: Skateboard wheels are typically made of plastic, offering various sizes and hardness levels to suit different riding styles.

- 13. Boat Trailer Rollers: Rollers on boat trailers are commonly made of plastic, as they resist corrosion when exposed to water and provide smooth boat launching and retrieval.

- 14. Gate Hardware: Some gate wheels and sliding door systems feature plastic wheels for smooth operation and reduced noise.

These examples demonstrate the widespread use of plastic wheels in diverse applications, emphasizing their adaptability and suitability for various industries and products.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

Can you describe the factors to consider when selecting plastic wheels for specific applications?

Selecting the right plastic wheels for specific applications involves considering several crucial factors to ensure optimal performance and durability. Here are the key factors to keep in mind:

- 1. Load Capacity: Determine the weight that the wheels will need to support in your application. Choose wheels with a load capacity that comfortably exceeds the maximum expected load to prevent overloading and premature wear.

- 2. Wheel Diameter: The diameter of the wheel affects its stability, ease of rolling, and ability to overcome obstacles. Select a wheel diameter that suits the terrain and surface conditions in your application.

- 3. Tread Design: Consider the tread pattern on the wheel. Smooth treads offer lower rolling resistance, while treaded or ribbed designs provide better traction. Choose the tread type that aligns with your application’s requirements.

- 4. Material Selection: Plastic wheels are available in various materials, such as polyurethane, polypropylene, and nylon. The choice of material should consider factors like durability, impact resistance, chemical resistance, and temperature resistance based on your application’s environment.

- 5. Bearing Type: Determine the bearing type used in the wheels. Precision bearings, like ball bearings or roller bearings, reduce friction and ensure smooth rolling. Choose bearings appropriate for your application’s load and usage frequency.

- 6. Environment: Assess the operating environment. Consider factors such as exposure to moisture, chemicals, extreme temperatures, and potential corrosion. Select wheels that are suitable for the conditions they will encounter.

- 7. Floor Protection: If your application involves rolling on delicate flooring, consider wheels with softer materials or non-marking properties to protect the floor from damage or marking.

- 8. Mobility and Maneuverability: Evaluate the required mobility and maneuverability of your equipment or vehicle. Swivel casters may be needed for tight spaces, while fixed wheels offer stability in straight-line movement.

- 9. Noise Level: Consider the noise level generated by the wheels. Some applications, like office furniture, require quiet operation. Choose wheels designed to minimize noise if noise is a concern.

- 10. Maintenance: Assess the maintenance requirements of the wheels. Some wheels may require regular lubrication or cleaning, while others are low-maintenance. Ensure that the maintenance demands align with your operational capabilities.

- 11. Mounting and Attachment: Check the compatibility of the wheel’s mounting and attachment method with your equipment or vehicle. The design should securely attach to prevent wobbling or detachment.

- 12. Budget: Consider your budget constraints. Different types of plastic wheels come at various price points. Balance your budget with the need for quality and durability.

By carefully evaluating these factors and selecting plastic wheels that align with your specific application’s requirements, you can ensure that your equipment or vehicle operates optimally, efficiently, and safely.

editor by Dream 2024-05-08

China best Custom Transmission Plastic Shaft Gear Chain Wheel

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Our Machine

Product Range

Contact Us /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Plastic |

| Customization: |

Available

|

|

|---|

Can plastic wheels be customized for specific uses or environments?

Yes, plastic wheels can be customized for specific uses or environments to meet unique requirements and applications. Customization options for plastic wheels include:

- 1. Material Selection: Plastic wheels can be manufactured from various types of plastics, each with specific properties. Depending on the application, you can choose the most suitable plastic material to optimize factors like durability, chemical resistance, temperature tolerance, and load-bearing capacity.

- 2. Load Capacity: Custom plastic wheels can be designed with specific load-bearing capabilities in mind. Reinforcements and modifications to the wheel’s structure can be made to increase its load capacity, ensuring it can handle the intended weight.

- 3. Wheel Diameter: The size and diameter of the wheel can be customized to match the terrain and space constraints of the application. Whether you need smaller or larger wheels, customization is possible to ensure a perfect fit.

- 4. Tread Design: The tread pattern on plastic wheels can be tailored to provide optimal traction, stability, and noise reduction for specific environments. Different tread designs are available to suit various surfaces and conditions.

- 5. Bearings: Custom plastic wheels can be equipped with different types of bearings to meet performance requirements. Precision bearings, sealed bearings, or special bearing configurations can be chosen based on the application’s demands.

- 6. Environment-Specific Features: Plastic wheels can be customized with features like corrosion-resistant coatings, anti-static properties, UV resistance, and non-marking materials to accommodate specific environmental conditions.

- 7. Color and Aesthetics: Custom plastic wheels can be produced in various colors and finishes to match the aesthetics of the equipment or environment they are used in. This is common in applications like office furniture and consumer products.

- 8. Mounting Options: Custom wheels can be designed with specific mounting and attachment options to ensure a secure fit with the equipment or vehicle. Custom hubs or axle configurations can be provided.

- 9. Specialized Applications: For highly specialized applications, such as aerospace, healthcare, or automotive, plastic wheels can be customized to meet stringent industry standards and certifications.

- 10. Prototyping and Testing: Customization often involves prototyping and testing to ensure that the wheels meet the desired performance criteria. Manufacturers can work closely with customers to develop and refine custom wheel designs.

Customized plastic wheels are valuable for industries and applications with specific needs, ensuring that the wheels perform optimally and contribute to the overall functionality and efficiency of equipment or systems.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

How does the design of a plastic wheel contribute to its durability and performance?

The design of a plastic wheel plays a significant role in determining its durability and performance. Several key design factors contribute to these attributes:

- 1. Material Selection: The choice of plastic material is crucial. High-quality plastics, such as polyurethane, polypropylene, and nylon, are commonly used for wheel construction. These materials offer excellent durability, impact resistance, and resistance to wear and tear.

- 2. Load Capacity: The design of the wheel must consider the expected load capacity. Reinforcements, such as ribbing or internal structures, can be added to strengthen the wheel and enhance its load-bearing capabilities. Proper load capacity design ensures that the wheel can support the intended weight without deformation or failure.

- 3. Bearing Type: The design of the wheel includes the type of bearing used. Precision bearings, such as ball bearings or roller bearings, reduce friction and ensure smooth rolling. Properly designed bearings enhance the wheel’s performance by reducing resistance and minimizing wear.

- 4. Tread Design: The tread design on the wheel affects its grip, stability, and noise level. Different tread patterns are used for specific applications. For example, smooth treads provide reduced rolling resistance, while treaded designs offer improved traction. The choice of tread design depends on the intended use.

- 5. Hub and Axle Compatibility: The design of the wheel’s hub and axle connection is essential for secure attachment. It should be compatible with the mounting hardware used in the application. A well-designed hub and axle connection ensure stability and prevent wobbling or detachment during use.

- 6. Resilience: The design should consider the wheel’s ability to absorb shocks and impacts. Resilient plastic materials can withstand sudden impacts without cracking or breaking. This is especially important in applications where the wheel may encounter rough terrain or obstacles.

- 7. Temperature Resistance: Depending on the application, plastic wheels may need to withstand a wide range of temperatures. The design should factor in the material’s temperature resistance to ensure that the wheel remains functional in extreme conditions.

- 8. Size and Dimensions: The size and dimensions of the wheel are critical for load distribution and stability. Properly sizing the wheel according to the application’s requirements ensures optimal performance and durability.

- 9. Corrosion Resistance: In some environments, corrosion resistance is essential. The design may incorporate materials or coatings that protect against corrosion, ensuring a longer service life.

- 10. Wheel Mounting: The method of mounting the wheel to the equipment or vehicle is part of the design. It should be secure and reliable to prevent wobbling or detachment during use.

- 11. Weight Distribution: Proper weight distribution across the wheel is important for even wear and reduced stress on the wheel. Design considerations may include the wheel’s shape and load-bearing capacity to ensure even weight distribution.

A well-designed plastic wheel takes into account these factors to maximize its durability and performance. It should be capable of withstanding the demands of its intended application while providing smooth and reliable movement.

editor by Dream 2024-05-08

China OEM RV Reducer Worm Gear Reduction Gearbox with Right Angle Transmission with Great quality

Solution Description

Merchandise Description

Main Resources:

one)housing:aluminium alloy ADC12(dimension 571-090) die cast iron HT200(measurement 110-a hundred and fifty)

two)Worm:20Cr, ZI Involute profile carbonize&quencher heat remedy make equipment area hardness up to 56-sixty two HRC Soon after precision grinding, carburization layer’s thickness amongst .3-.5mm.

three)Worm Wheel:wearable stannum alloy CuSn10-1

Detailed Pictures

Mixture Possibilities:

Enter:with enter shaft, With square flange,With IEC standard input flange

Output:with torque arm, output flange, one output shaft, double output shaft, plastic go over

Worm reducers are available with diffferent combos: NMRV+NMRV, NMRV+NRV, NMRV+Computer, NMRV+UDL, NMRV+MOTORS

Exploded View:

Merchandise Parameters

GMRV Define Dimension:

Firm Profile

About CZPT Transmission:

We are a professional reducer company positioned in HangZhou, ZHangZhoug province.

Our leading merchandise is full variety of RV571-a hundred and fifty worm reducers , also equipped GKM hypoid helical gearbox, GRC inline helical gearbox, Laptop models, UDL Variators and AC Motors, G3 helical equipment motor.

Merchandise are broadly used for apps these kinds of as: foodstuffs, ceramics, packing, chemical compounds, pharmacy, plastics, paper-making, building equipment, metallurgic mine, environmental security engineering, and all types of automated lines, and assembly traces.

With fast shipping, exceptional right after-revenue service, superior making facility, our merchandise promote well both at house and abroad. We have exported our reducers to Southeast Asia, Jap Europe and Middle East and so on.Our aim is to create and innovate on basis of large good quality, and produce a good status for reducers.

Packing details:Plastic Luggage+Cartons+Wooden Situations , or on request

We take part Germany Hannver Exhibition-ZheJiang PTC Honest-Turkey Get Eurasia

Logistics

Right after Revenue Services

1.Maintenance Time and Warranty:Within 1 calendar year right after acquiring merchandise.

two.Other Service: Such as modeling assortment information, set up information, and issue resolution guide, etc.

FAQ

one.Q:Can you make as per client drawing?

A: Indeed, we offer customized provider for buyers accordingly. We can use customer’s nameplate for gearboxes.

2.Q:What is your phrases of payment ?

A: 30% deposit prior to production,equilibrium T/T just before shipping.

3.Q:Are you a trading organization or manufacturer?

A:We are a manufacurer with advanced equipment and skilled personnel.

four.Q:What’s your production ability?

A:8000-9000 PCS/Thirty day period

five.Q:Free sample is available or not?

A:Sure, we can source totally free sample if client agree to pay out for the courier price

6.Q:Do you have any certificate?

A:Yes, we have CE certificate and SGS certification report.

Speak to data:

Ms Lingel Pan

For any inquiries just truly feel free ton contact me. Several thanks for your kind attention to our company!

How to Pick a Worm Shaft and Equipment For Your Project

You will understand about axial pitch PX and tooth parameters for a Worm Shaft 20 and Equipment 22. Detailed data on these two components will help you pick a appropriate Worm Shaft. Read on to learn much more….and get your arms on the most innovative gearbox ever developed! Here are some suggestions for choosing a Worm Shaft and Gear for your task!…and a few items to hold in head.

Gear 22

The tooth profile of Equipment 22 on Worm Shaft 20 differs from that of a traditional gear. This is due to the fact the tooth of Equipment 22 are concave, enabling for better conversation with the threads of the worm shaft twenty. The worm’s guide angle leads to the worm to self-lock, stopping reverse movement. However, this self-locking mechanism is not fully trusted. Worm gears are employed in several industrial applications, from elevators to fishing reels and automotive energy steering.

The new equipment is put in on a shaft that is secured in an oil seal. To install a new equipment, you initial need to have to remove the previous equipment. Following, you need to unscrew the two bolts that keep the equipment on to the shaft. Next, you need to get rid of the bearing provider from the output shaft. After the worm equipment is taken off, you want to unscrew the retaining ring. Right after that, set up the bearing cones and the shaft spacer. Make confident that the shaft is tightened appropriately, but do not in excess of-tighten the plug.

To avert premature failures, use the proper lubricant for the sort of worm equipment. A higher viscosity oil is necessary for the sliding action of worm gears. In two-thirds of purposes, lubricants have been inadequate. If the worm is flippantly loaded, a reduced-viscosity oil may possibly be ample. Or else, a large-viscosity oil is needed to preserve the worm gears in excellent problem.

One more alternative is to fluctuate the quantity of tooth all around the gear 22 to reduce the output shaft’s speed. This can be completed by location a certain ratio (for instance, five or 10 moments the motor’s pace) and modifying the worm’s dedendum accordingly. This approach will decrease the output shaft’s velocity to the preferred degree. The worm’s dedendum must be tailored to the desired axial pitch.

Worm Shaft 20

When choosing a worm gear, contemplate the adhering to items to take into account. These are substantial-overall performance, lower-noise gears. They are sturdy, minimal-temperature, and lengthy-long lasting. Worm gears are commonly utilised in many industries and have several positive aspects. Outlined beneath are just some of their rewards. Study on for much more information. Worm gears can be challenging to sustain, but with correct routine maintenance, they can be very reputable.

The worm shaft is configured to be supported in a body 24. The dimensions of the body 24 is decided by the middle distance in between the worm shaft twenty and the output shaft sixteen. The worm shaft and equipment 22 could not arrive in speak to or interfere with a single yet another if they are not configured effectively. For these causes, correct assembly is crucial. Nonetheless, if the worm shaft 20 is not properly set up, the assembly will not perform.

Yet another essential thing to consider is the worm material. Some worm gears have brass wheels, which might lead to corrosion in the worm. In addition, sulfur-phosphorous EP equipment oil activates on the brass wheel. These supplies can result in substantial loss of load surface. Worm gears need to be installed with high-top quality lubricant to avoid these issues. There is also a require to decide on a materials that is substantial-viscosity and has reduced friction.

Pace reducers can consist of numerous various worm shafts, and each and every speed reducer will demand various ratios. In this case, the speed reducer manufacturer can give distinct worm shafts with distinct thread designs. The various thread styles will correspond to diverse gear ratios. Irrespective of the equipment ratio, every worm shaft is created from a blank with the desired thread. It will not be hard to discover 1 that matches your requirements.

Equipment 22’s axial pitch PX

The axial pitch of a worm equipment is calculated by using the nominal heart length and the Addendum Aspect, a consistent. The Middle Distance is the length from the middle of the equipment to the worm wheel. The worm wheel pitch is also called the worm pitch. Both the dimension and the pitch diameter are taken into thought when calculating the axial pitch PX for a Equipment 22.

The axial pitch, or lead angle, of a worm equipment establishes how efficient it is. The greater the guide angle, the less productive the gear. Guide angles are immediately relevant to the worm gear’s load potential. In distinct, the angle of the guide is proportional to the duration of the pressure region on the worm wheel enamel. A worm gear’s load potential is immediately proportional to the volume of root bending anxiety introduced by cantilever action. A worm with a lead angle of g is practically identical to a helical equipment with a helix angle of 90 deg.

In the current invention, an improved approach of producing worm shafts is explained. The strategy entails figuring out the preferred axial pitch PX for every reduction ratio and frame measurement. The axial pitch is recognized by a technique of production a worm shaft that has a thread that corresponds to the preferred equipment ratio. A equipment is a rotating assembly of components that are produced up of enamel and a worm.

In addition to the axial pitch, a worm gear’s shaft can also be created from diverse components. The material utilized for the gear’s worms is an important thing to consider in its assortment. Worm gears are generally produced of steel, which is much better and corrosion-resistant than other materials. They also call for lubrication and might have ground tooth to lessen friction. In addition, worm gears are frequently quieter than other gears.

Gear 22’s tooth parameters

A review of Equipment 22’s tooth parameters unveiled that the worm shaft’s deflection is dependent on different aspects. The parameters of the worm gear have been varied to account for the worm gear dimensions, force angle, and measurement element. In addition, the quantity of worm threads was changed. These parameters are different based mostly on the ISO/TS 14521 reference equipment. This study validates the created numerical calculation product making use of experimental outcomes from Lutz and FEM calculations of worm gear shafts.

Utilizing the final results from the Lutz examination, we can receive the deflection of the worm shaft employing the calculation method of ISO/TS 14521 and DIN 3996. The calculation of the bending diameter of a worm shaft according to the formulation offered in AGMA 6022 and DIN 3996 present a very good correlation with take a look at final results. Even so, the calculation of the worm shaft utilizing the root diameter of the worm employs a different parameter to estimate the equal bending diameter.

The bending stiffness of a worm shaft is calculated by means of a finite component design (FEM). Using a FEM simulation, the deflection of a worm shaft can be calculated from its toothing parameters. The deflection can be considered for a comprehensive gearbox technique as stiffness of the worm toothing is considered. And last but not least, based on this review, a correction element is developed.

For an perfect worm equipment, the quantity of thread starts is proportional to the dimension of the worm. The worm’s diameter and toothing factor are calculated from Equation 9, which is a formula for the worm gear’s root inertia. The distance amongst the main axes and the worm shaft is identified by Equation 14.

Gear 22’s deflection

To research the impact of toothing parameters on the deflection of a worm shaft, we utilised a finite element strategy. The parameters regarded as are tooth top, force angle, measurement issue, and number of worm threads. Every single of these parameters has a various influence on worm shaft bending. Desk 1 demonstrates the parameter versions for a reference gear (Equipment 22) and a various toothing model. The worm gear measurement and number of threads decide the deflection of the worm shaft.

The calculation technique of ISO/TS 14521 is based on the boundary problems of the Lutz check set up. This technique calculates the deflection of the worm shaft employing the finite factor strategy. The experimentally measured shafts ended up in contrast to the simulation outcomes. The take a look at results and the correction element had been when compared to confirm that the calculated deflection is equivalent to the calculated deflection.

The FEM evaluation suggests the impact of tooth parameters on worm shaft bending. Gear 22’s deflection on Worm Shaft can be described by the ratio of tooth drive to mass. The ratio of worm tooth power to mass establishes the torque. The ratio among the two parameters is the rotational pace. The ratio of worm equipment tooth forces to worm shaft mass establishes the deflection of worm gears. The deflection of a worm gear has an effect on worm shaft bending potential, efficiency, and NVH. The continuous improvement of energy density has been attained by way of developments in bronze materials, lubricants, and production top quality.

The main axes of second of inertia are indicated with the letters A-N. The three-dimensional graphs are identical for the 7-threaded and 1-threaded worms. The diagrams also show the axial profiles of each and every equipment. In addition, the major axes of moment of inertia are indicated by a white cross.

China Hot selling RV030-150 Power Transmission Worm Gear Box with Synthetic Oil with Hot selling

Merchandise Description

Product Description

Primary Resources:

1)housing:aluminium alloy ADC12(dimensions 571-090) die solid iron HT200(dimensions 110-150)

two)Worm:20Cr, ZI Involute profile carbonize&quencher warmth treatment method make equipment surface area hardness up to 56-sixty two HRC Following precision grinding, carburization layer’s thickness among .3-.5mm.

3)Worm Wheel:wearable stannum alloy CuSn10-1

Detailed Pictures

Mixture Possibilities:

Input:with input shaft, With square flange,With IEC regular input flange

Output:with torque arm, output flange, single output shaft, double output shaft, plastic cover

Worm reducers are available with diffferent combinations: NMRV+NMRV, NMRV+NRV, NMRV+Laptop, NMRV+UDL, NMRV+MOTORS

Exploded Look at:

Product Parameters

GMRV Outline Dimension:

Firm Profile

About CZPT Transmission:

We are a professional reducer maker located in HangZhou, ZHangZhoug province.

Our foremost products is full selection of RV571-150 worm reducers , also equipped GKM hypoid helical gearbox, GRC inline helical gearbox, Computer models, UDL Variators and AC Motors, G3 helical gear motor.

Items are widely utilized for purposes these kinds of as: foodstuffs, ceramics, packing, chemical compounds, pharmacy, plastics, paper-creating, design equipment, metallurgic mine, environmental defense engineering, and all types of automated lines, and assembly traces.

With quickly supply, exceptional following-product sales support, innovative generating facility, our items offer well both at property and overseas. We have exported our reducers to Southeast Asia, Japanese Europe and Center East and so on.Our goal is to create and innovate on basis of large quality, and develop a good reputation for reducers.

Packing data:Plastic Luggage+Cartons+Picket Cases , or on request

We take part Germany Hannver Exhibition-ZheJiang PTC Fair-Turkey Earn Eurasia

Logistics

Soon after Product sales Service

1.Servicing Time and Guarantee:Inside of 1 calendar year following receiving products.

2.Other Support: Such as modeling selection guidebook, set up guidebook, and dilemma resolution information, etc.

FAQ

1.Q:Can you make as per client drawing?

A: Yes, we offer you custom-made support for consumers appropriately. We can use customer’s nameplate for gearboxes.

two.Q:What is your terms of payment ?

A: 30% deposit before creation,balance T/T ahead of shipping.

three.Q:Are you a trading firm or company?

A:We are a manufacurer with sophisticated products and skilled employees.

four.Q:What is your creation capacity?

A:8000-9000 PCS/Month

5.Q:Cost-free sample is available or not?

A:Of course, we can source free sample if client concur to pay for the courier cost

6.Q:Do you have any certification?

A:Indeed, we have CE certification and SGS certificate report.

Make contact with data:

Ms Lingel Pan

For any questions just really feel cost-free ton speak to me. Many thanks for your sort consideration to our firm!

What Is a Worm Equipment Reducer?

If you have never ever witnessed a worm gear reducer before, you’re missing out! Find out far more about these outstanding gears and their programs by reading through this article! In addition to worm equipment reducers, find out about worms and how they are produced. You will also uncover what sorts of equipment can gain from worm gears, this kind of as rock crushers and elevators. The pursuing information will assist you recognize what a worm equipment reducer is and how to discover 1 in your location.

Typical worm shaft

A typical worm has two shafts, one for advancing and a single for receding, which kind the axial pitch of the equipment. Normally, there are 8 regular axial pitches, which establish a basic dimension for worm generation and inspection. The axial pitch of the worm equals the round pitch of the gear in the central airplane and the grasp guide cam’s radial pitch. A solitary established of alter gears and a single master direct cam are utilised to make every size of worm.

Worm gear is commonly employed to manufacture a worm shaft. It is a reputable and successful gear reduction technique that does not go when the power is eliminated. Typical worm gears appear in common sizes as properly as assisted methods. Makers can be identified online. Listed below are some widespread components for worm gears. There are also a lot of choices for lubrication. The worm gear is typically manufactured from case hardened steel or bronze. Non-metallic components are also used in light-weight-obligation programs.

A self-locking worm gear prevents the worm from transferring backwards. Common worm gears are typically self-locking when the guide angle is less than 11 degrees. Nevertheless, this characteristic can be detrimental to systems that require reverse sensitivity. If the direct angle is less than 4 levels, again-driving is unlikely. Nevertheless, if fall short-safe security is a prerequisite, back again-driving worm gears have to have a constructive brake to keep away from reverse motion.

Worm gears are typically utilized in transmission applications. They are a more effective way to reduce the speed of a device compared to traditional equipment sets. Their decreased velocity is attainable thanks to their minimal ratio and couple of parts. In contrast to standard equipment sets, worm gears demand much less servicing and lower mechanical failure than a typical gear set. Whilst they require less areas, worm gears are also far more resilient than conventional equipment sets.

There are two sorts of worm tooth types. Convex and involute helicoids have distinct types of enamel. The former makes use of a straight line to intersect the involute worm creating line. The latter, on the other hand, makes use of a trapezoid primarily based on the central cross section of the root. Equally of these tooth varieties are employed in the production of worms. And they have different variations in pitch diameter.

Varieties of worms

Worms have numerous forms of tooth. For convenience in generation, a trapezoid-based mostly tooth kind is used. Other varieties include an involute helicoidal or a convolute worm making a line. The subsequent is a description of every sort. All kinds are equivalent, and some may possibly be chosen more than others. Shown below are the three most widespread worm shaft kinds. Every variety has its own advantages and drawbacks.

Discrete as opposed to parallel axis: The style of a worm gear decides its ratio of torque. It is a mix of two distinct metals – one particular for the worm and one particular for the wheel – which aids it soak up shock loads. Construction products and off-street automobiles usually demand different torques to maneuver above diverse terrain. A worm equipment system can aid them maneuver in excess of uneven terrain with out creating abnormal put on.

Worm gear models have the optimum ratio. The sliding motion of the worm shaft results in a large self-locking torque. Based on the angle of inclination and friction, a worm equipment can reach up to one hundred:1! Worm gears can be manufactured of various materials depending on their inclination and friction angle. Worm gears are also helpful for equipment reduction purposes, this kind of as lubrication or grinding. Nevertheless, you must think about that heavier gears are likely to be more challenging to reverse than lighter types.

Metallic alloy: Stainless steel, brass, and aluminum bronze are widespread materials for worm gears. All 3 kinds have special positive aspects. A bronze worm equipment is generally composed of a mix of copper, zinc, and tin. A bronze shaft is far more corrosive than a brass 1, but it is a resilient and corrosion-resistant choice. Metallic alloys: These components are utilized for equally the worm wheel.

The performance of worm gears relies upon on the assembly situations and the lubricant. A 30:1 ratio reduces the effectiveness to eighty one:1%. A worm gear is a lot more productive at increased ratios than an helical gear, but a 30:1 ratio reduces the performance to eighty one%. A helical gear lowers pace whilst preserving torque to close to fifteen% of the first velocity. The variation in effectiveness amongst worm equipment and helical equipment is about fifty percent an hour!

Approaches of manufacturing worm shafts

Several approaches of production worm shafts are obtainable in the market. Solitary-pointed lathe resources or end mills are the most common strategies for manufacturing worms. These resources are capable of creating worms with different strain angles dependent on their diameter, the depth of thread, and the grinding wheel’s diameter. The diagram beneath demonstrates how different strain angles affect the profile of worms created utilizing diverse reducing instruments.

The method for creating worm shafts entails the procedure of establishing the appropriate outer diameter of a frequent worm shaft blank. This could incorporate thinking about the number of reduction ratios in a household, the distance in between the worm shaft and the equipment set centre, as effectively as the torques included. These procedures are also referred to as ‘thread assembly’. Each and every procedure can be additional refined if the sought after axial pitch can be achieved.

The axial pitch of a worm should match the round pitch of the greater gear. This is referred to as the pitch. The pitch diameter and axial pitch have to be equal. Worms can be left-handed or right-handed. The direct, which refers to the distance a position on the thread travels throughout 1 revolution of the worm, is outlined by its angle of tangent to the helix on the pitch of the cylinder.

Worm shafts are frequently manufactured making use of a worm equipment. Worm gears can be used in distinct applications since they offer fantastic adjustment and large gear reduction. They can be made in each normal dimensions and assisted methods. Worm shaft makers can be located on the internet. Alternatively, you can speak to a maker right to get your worm gears made. The method will get only a couple of minutes. If you are seeking for a producer of worm gears, you can browse a directory.

Worm gears are made with hardened metal. The worm wheel and equipment are yellow in colour. A compounded oil with rust and oxidation inhibitors is also utilized to make worm gears. These oils adhere to the shaft partitions and make a protecting barrier amongst the surfaces. If the compounded oil is applied accurately, the worm equipment will minimize the noise in a motor, resulting in a smoother performance.

programs for worm gear reducers

Worm gears are commonly used in power transmission applications, supplying a compact, higher reduction, low-velocity drive. To establish the torque ratio of worm gears, a numerical model was developed that can make use of the equation of displacement compatibility and the impact coefficient approach, which offers quick computing. The numerical model also incorporates bending deflections of the gear surfaces and the mating surfaces. It is based mostly on the Boussinesq theory, which calculates nearby speak to deformations.

Worm gears can be developed to be correct or still left-handed, and the worm can change either clockwise or counter-clockwise. An internal helical gear requires the very same hand to function both components. In distinction, an external helical equipment must be operated by the opposite hand. The very same theory applies to worm gears in other programs. The torque and electricity transferred can be large, but worm gears are able to cope with large reductions in equally directions.

Worm gears are extremely useful in industrial equipment styles. They lessen sounds ranges, conserve place, and give machines additional precision and quick-stopping abilities. Worm gears are also available in compact versions, creating them ideal for hoisting applications. This kind of gear reducer is utilized in industrial settings the place space is an problem. Its more compact dimensions and considerably less noise helps make it excellent for purposes that require the machine to quit quickly.

A double-throated worm equipment delivers the highest load potential whilst nevertheless remaining compact. The double-throated version characteristics concave enamel on both worm and gear, doubling the get in touch with area in between them. Worm gears are also beneficial for low to average-horsepower purposes, and their substantial ratios, higher output torque, and substantial speed reduction make them a appealing choice for a lot of applications. Worm gears are also quieter than other kinds of gears, minimizing the noise and vibrations that they cause.

Worm gears have quite a few rewards over other kinds of gears. They have high levels of conformity and can be classified as a screw pair within a reduced-pair gear household. Worm gears are also known to have a substantial diploma of relative sliding. Worm gears are frequently created of hardened steel or phosphor-bronze, which supplies good area finish and rigid positioning. Worm gears are lubricated with particular lubricants that incorporate floor-energetic additives. Worm equipment lubrication is a mixed lubrication process and brings about gentle wear and tear.

China supplier HW19710 High Grade Custom Good Auto Gearbox Transmission Assembly Gear Box For Cars Trucks near me supplier

12 months: 2005-, 2005-, -, 2006-

Product: Howo, Steyr, Golden Prince, CZPT A7

OE NO.: HW19710

Car Fitment: CZPT (CNHTC)

Type: Transmission Assembly

Dimensions: 950.00*600.00*five hundred.00 mm

Design Amount: HW19710

Truck Model: Howo

Item name: Gearbox Transmission Assembly Equipment Box For Trucks

Fat: 376 kg

Deal: Plastic/ Carton/ wood box/ Pallet

Color: Customer Needs

Service: OEM&ODM

MOQ: 1set

Relevant vehicle: CZPT HOWO

Substance: Standard materials

Good quality: one hundred% analyzed

Products variety: Transimission Components

Packaging Information: Plastic/ Carton/ wood box/ Pallet

Port: HangZhou

Goods Exhibit Truck Parts NameGearbox Transmission Assembly Equipment Box For Automobiles TrucksTruck Part-Design Numberstandard Gearbox Transmission AssemblySize950.00*600.00*500.00 mmWeightstandardMOQ1 pcs/setSupply Ability10000 Set/Sets for each dayWarranty3 monthsPriceSend inquiry to get the most recent pricePackagePlastic/ Carton/ picket box/ PalletDelivery Time3-5 days with inventory and 20-fifty day for CustomizedColorCustomer DemandsServiceWe settle for OEM&ODM . Connected Product Business Profile ZheJiang Huachang Provide Chain Technologies Co., LtdZheJiang Huachang Offer Chain Technologies Co., Ltd. was proven in 2005, we have fifteen,000-square-meter warehouse with in excess of five hundred personnel, 36 professionals and designers and 32 quality inspectors. We have targeted on producing, design and style, 130401-00014 Vacation Reduction Gearbox S255LC-V Excavator Component custom-made answer, item improvement and sourcing. With much more than fifteen many years expertise in the industry, we will offer you greater high quality, more efficient, far more dependable answers.We mostly engage in different truck parts:* Truck Engine components and peripheral components , such as generator, various filter elements, cylinder liner kits, and many others. *Truck Chassis areas, including clutch, push rod, all kinds of brake valves, and so on. Hot Sale Worm Gearbox Reducer With Electrical Motor * Truck Gearbox elements, which includes all types of gears, shafting, and so on. * Truck Taxi areas: bumpers, fenders, doorway assembly, and many others.* Other Truck Elements and accessories. Exhibition Packing & Shipping and delivery FAQ FAQQ: What to do if I do not know the part quantity? A: If you give us the chassis variety or the parts photographs, we can offer the proper parts you essential. Q: What is your conditions of packing? A: Typically, we pack our items in neutral white boxes and brown cartons. If you have legally registered patent, we can pack the merchandise in your branded boxes following getting your authorization letters. Q: Can you provide other spare components? A: Yes, ZF5HP19 5HP19 Automated Transmission Oil Pump For Audi BMW Gearbox Pump 1060 410 017 of training course. As you know, 1 truck has hundreds of areas so that we can’t show all of them. Just explain to us much more particulars, we’ll discover them for you. Q: Why must we buy from your organization not other supplier? A: We preserve good high quality and competitive price tag to make certain our buyers gain. All our item are one hundred% testing prior to shipment.Huachang has been proactive provide you greater top quality, more efficient, far more trustworthy answers for in excess of ten several years expertise. Q:What is your conditions of delivery? A: EXW, FOB, CFR, CIF, DDU. Q: Can you produce according to the samples? A: Yes, we can create by your samples or technological drawings. We can construct the molds and fixtures. Q: What is actually the delivery time? A: Most of areas are available in storage. So can shipping and delivery in 2 days following payment. For the ones no storage, can shipping and delivery in 7 times. For container shipping, MLX Series Bevel & Planetary Equipment Vertical Mounting Vertical Mill Gearboxes for Cement Coal Mills 1 container can complete loading in 10 times.

Key Marketplace Insights Related to Worm Reduction Gearboxes

A gearbox is a mechanical gadget that makes it possible for you to shift between diverse speeds or gears. It does so by using one particular or far more clutches. Some gearboxes are single-clutch, even though other people use two clutches. You can even discover a gearbox with shut bladders. These are also known as dual clutches and can shift gears more quickly than other types. Functionality vehicles are designed with these sorts of gearboxes.

Backlash measurement

Gearbox backlash is a frequent ingredient that can result in noise or other troubles in a auto. In truth, the beats and sets of gears in a gearbox are often excited by the oscillations of the motor torque. Sound from gearboxes can be substantial, specifically in secondary shafts that engage output gears with a differential ring. To measure backlash and other dimensional versions, an operator can periodically consider the output shaft’s motion and assess it to a identified value.

A comparator measures the angular displacement amongst two gears and shows the benefits. In 1 approach, a secondary shaft is disengaged from the gearbox and a handle gauge is attached to its conclude. A threaded pin is utilised to secure the differential crown to the secondary shaft. The output pinion is engaged with the differential ring with the assist of a management gauge. The angular displacement of the secondary shaft is then calculated by employing the dimensions of the output pinion.

Backlash measurements are essential to make sure the smooth rotation of meshed gears. There are various kinds of backlash, which are categorized according to the type of equipment utilised. The first type is called circumferential backlash, which is the length of the pitch circle close to which the equipment rotates to make speak to. The 2nd type, angular backlash, is described as the optimum angle of movement between two meshed gears, which makes it possible for the other equipment to go when the other equipment is stationary.

The backlash measurement for gearbox is one of the most essential checks in the production method. It is a criterion of tightness or looseness in a gear set, and too much backlash can jam a gear set, creating it to interface on the weaker component of its equipment tooth. When backlash is too limited, it can guide to gears jamming beneath thermal expansion. On the other hand, too much backlash is bad for overall performance.

Worm reduction gearboxes

Worm reduction gearboxes are used in the creation of a lot of various varieties of machines, which includes metal and power crops. They are also used extensively in the sugar and paper industries. The firm is constantly aiming to enhance their products and providers to remain aggressive in the worldwide marketplace. The following is a summary of crucial market insights related to this sort of gearbox. This report will aid you make informed business conclusions. Read through on to understand more about the rewards of this variety of gearbox.

In contrast to standard equipment sets, worm reduction gearboxes have few down sides. Worm equipment reducers are generally available and makers have standardized their mounting proportions. There are no exclusive specifications for shaft size, top, and diameter. This tends to make them a very flexible piece of gear. You can pick to use a single or blend a number of worm gear reducers to fit your particular application. And due to the fact they have standardized ratios, you will not have to fear about matching up numerous gears and figuring out which kinds suit.

A single of the major down sides of worm reduction gearboxes is their decreased performance. Worm reduction gearboxes normally have a greatest reduction ratio of 5 to sixty. The higher-performance hypoid gears have an output speed of all around 10 to twelve revolutions. In these situations, the diminished ratios are reduced than individuals with traditional gearing. Worm reduction gearboxes are usually more effective than hypoid gear sets, but they nevertheless have a lower performance.

The worm reduction gearboxes have several advantages more than traditional gearboxes. They are simple to keep and can function in a variety of different programs. Since of their diminished velocity, they are ideal for conveyor belt methods.

Worm reduction gearboxes with shut bladders

The worm and the equipment mesh with every other in a combination of sliding and rolling movements. This sliding action is dominant at substantial reduction ratios, and the worm and gear are made of dissimilar metals, which outcomes in friction and warmth. This limits the performance of worm gears to close to 30 to fifty p.c. A softer material for the equipment can be utilized to take in shock hundreds for the duration of operation.

A typical equipment modifications its output independently as soon as a sufficient load is used. Even so, the backstop complicates the equipment configuration. Worm gears call for lubrication because of the sliding wear and friction introduced throughout motion. A frequent gear arrangement moves electrical power at the peak load segment of a tooth. The sliding happens at lower speeds on both facet of the apex and takes place at a minimal velocity.

Solitary-reduction gearboxes with closed bladders may possibly not demand a drain plug. The reservoir for a worm equipment reducer is developed so that the gears are in consistent make contact with with lubricant. However, the closed bladders will cause the worm gear to dress in out much more speedily, which can result in premature use and enhanced energy use. In this case, the gears can be changed.

Worm gears are frequently utilized for pace reduction applications. In contrast to typical gear sets, worm gears have greater reduction ratios. The number of gear tooth in the worm minimizes the pace of a certain motor by a sizeable quantity. This tends to make worm gears an eye-catching choice for hoisting apps. In addition to their elevated performance, worm gears are compact and considerably less susceptible to mechanical failure.

Shaft arrangement of a gearbox

The ray-diagram of a gearbox demonstrates the arrangement of gears in the various shafts of the transmission. It also exhibits how the transmission produces distinct output speeds from a single velocity. The ratios that depict the speed of the spindle are named the phase ratio and the progression. A French engineer named Charles Renard introduced 5 simple collection of gearbox speeds. The 1st collection is the equipment ratio and the 2nd series is the reverse gear ratio.