Product Description

Product Description

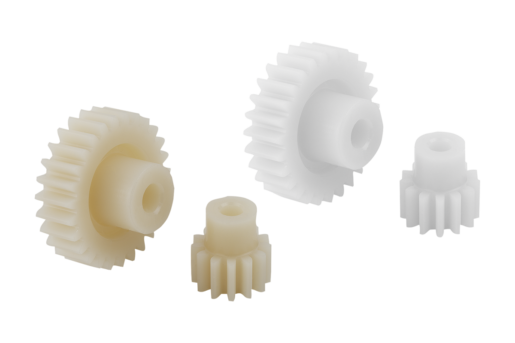

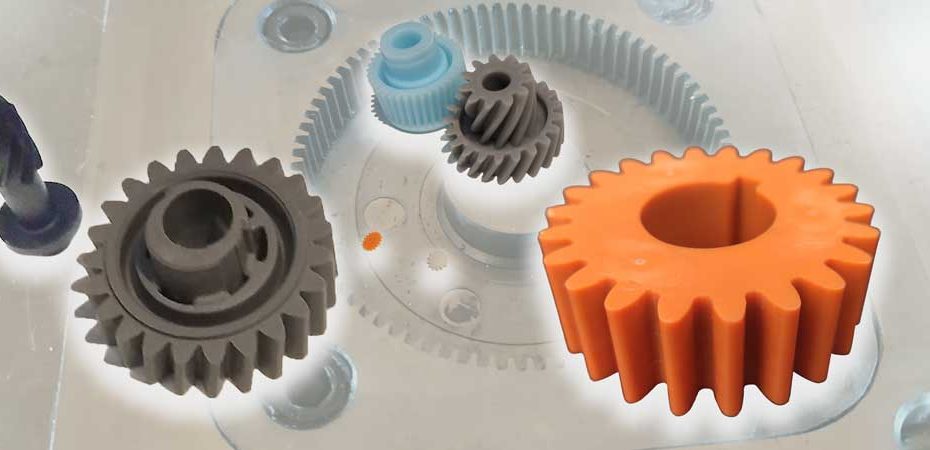

Machine Nylon Drive Transmission Injection Plastic Toothed Cylindrical Straight Spur Gear Cog-Wheel

| Item | Customized Injection and machining gears | |

| Process | Injection molding,CNC machining, | |

| material | Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that commonly use plastic wheels?

Plastic wheels are used in a wide range of products and machinery across various industries due to their versatility and unique qualities. Here are examples of products and machinery that commonly use plastic wheels:

- 1. Office Furniture: Office chairs often feature plastic caster wheels for smooth and quiet movement on office floors.

- 2. Material Handling Equipment: Hand trucks, dollies, and carts used in warehouses and distribution centers frequently use plastic wheels to transport goods efficiently.

- 3. Lawn and Garden Equipment: Lawnmowers, garden carts, and wheelbarrows are equipped with plastic wheels for easy maneuverability on lawns and uneven terrain.

- 4. Retail and Shopping Carts: Shopping carts in supermarkets and retail stores typically have plastic wheels for easy navigation through aisles.

- 5. Medical Equipment: Hospital beds, medical carts, and mobility aids often incorporate plastic wheels, as they are easy to clean and resist corrosion.

- 6. Aerospace Ground Support: Ground support equipment at airports, including baggage carts and maintenance vehicles, may use plastic wheels for their lightweight properties.

- 7. Food and Beverage Handling: Food service equipment, such as serving trolleys and food processing machinery, often feature plastic wheels due to their resistance to moisture and corrosion.

- 8. Recreational Vehicles (RVs): RV leveling jacks and stabilizers utilize plastic wheels to provide stability and ease of adjustment when parked.

- 9. DIY and Home Improvement Tools: Hand trucks, utility carts, and toolboxes used for DIY and home improvement projects may have plastic wheels for ease of movement.

- 10. Industrial Machinery: Some industrial machines and equipment incorporate plastic wheels to facilitate movement and protect factory floors.

- 11. Conveyor Systems: Conveyor systems in manufacturing and logistics often use plastic wheels to support the movement of goods along production lines.

- 12. Skateboards and Skateboarding Equipment: Skateboard wheels are typically made of plastic, offering various sizes and hardness levels to suit different riding styles.

- 13. Boat Trailer Rollers: Rollers on boat trailers are commonly made of plastic, as they resist corrosion when exposed to water and provide smooth boat launching and retrieval.

- 14. Gate Hardware: Some gate wheels and sliding door systems feature plastic wheels for smooth operation and reduced noise.

These examples demonstrate the widespread use of plastic wheels in diverse applications, emphasizing their adaptability and suitability for various industries and products.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

What are the different types and sizes of plastic wheels available in the market?

The market offers a variety of plastic wheels, each designed for specific applications and available in various sizes. Here are different types and sizes of plastic wheels commonly available:

- 1. Caster Wheels: Caster wheels are used for mobility and swiveling in a wide range of applications. They come in sizes ranging from small, furniture casters to large, heavy-duty industrial casters.

- 2. Hand Truck Wheels: These wheels are commonly used on hand trucks and dollies for moving heavy loads. They are available in sizes such as 8-inch, 10-inch, and 12-inch diameters.

- 3. Trolley Wheels: Trolley wheels are used on material handling carts and trolleys. They come in various sizes, including 4-inch, 5-inch, and 6-inch diameters.

- 4. Lawnmower Wheels: These wheels are designed for lawnmowers and other outdoor equipment. They are available in sizes like 8-inch, 10-inch, and 12-inch diameters.

- 5. Office Chair Casters: Office chair casters come in different sizes to fit various chair bases. Common sizes include 2-inch, 2.5-inch, and 3-inch diameters.

- 6. Heavy-Duty Industrial Wheels: These wheels are used in industrial and manufacturing settings. They are available in larger sizes, such as 6 inches, 8 inches, and even up to 12 inches or more in diameter.

- 7. Skateboard Wheels: Plastic skateboard wheels come in various sizes, typically ranging from 50mm to 60mm in diameter, with different hardness levels for different riding styles.

- 8. Conveyor Wheels: Conveyor wheels are used in material handling and conveyor systems. They come in sizes suitable for specific conveyor designs and loads.

- 9. V-Groove Wheels: V-groove wheels are designed for use on tracks or grooves. They come in sizes suitable for different track profiles and load capacities.

- 10. Trailer Jack Wheels: Trailer jack wheels are used for trailer jacks and stabilizers. They come in sizes such as 6-inch, 8-inch, and 10-inch diameters.

- 11. Light-Duty Wheels: These wheels are used in various light-duty applications, such as small carts and furniture. They are available in sizes ranging from 1 inch to 6 inches in diameter.

- 12. Specialized Wheels: Some plastic wheels are designed for specific applications, such as luggage wheels, boat trailer rollers, and gate wheels. Their sizes vary depending on the intended use.

The availability of plastic wheels in different types and sizes allows them to cater to a wide range of industries and applications. When selecting a plastic wheel, it’s essential to consider factors like load capacity, wheel diameter, tread design, and material to ensure it meets the requirements of the specific use case.

editor by Dream 2024-05-17

China Custom Machine Custom Drive Precision Plastic Toothed Cylindrical Straight Spur Gear Cog Wheel

Product Description

Product Description

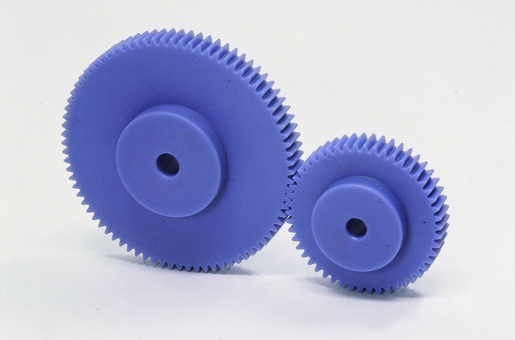

Machine Custom Drive Precision Plastic Toothed Cylindrical Straight Spur Gear Cog Wheel

| Item | Customized Injection and machining gears | |

| Process | Injection molding,CNC machining, | |

| material | Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does the choice of materials impact the performance of plastic wheels in different settings?

The choice of materials significantly impacts the performance of plastic wheels in various settings. Different plastics offer unique properties that make them suitable for specific applications and environments. Here’s how material choice affects plastic wheel performance:

- 1. Durability: High-quality plastics like polyurethane and nylon are known for their durability. They resist wear and tear, making them ideal for heavy-duty settings, such as industrial equipment or manufacturing environments.

- 2. Load Capacity: The material’s strength and rigidity influence a plastic wheel’s load-bearing capacity. Reinforced plastics or materials like glass-filled nylon can handle heavier loads compared to softer plastics like polypropylene.

- 3. Chemical Resistance: Certain plastic materials, such as polypropylene, offer excellent chemical resistance. They are suitable for applications where exposure to chemicals or acids is a concern, like laboratories or chemical processing plants.

- 4. Temperature Tolerance: Some plastics are designed to withstand extreme temperatures. For example, acetal (POM) wheels can handle both high and low-temperature environments, making them suitable for freezer or high-heat applications.

- 5. Moisture Resistance: Plastics like polyurethane and nylon are moisture-resistant and do not absorb water. This property ensures that the wheels remain functional even in wet conditions, such as outdoor use or in humid environments.

- 6. UV Resistance: UV-resistant plastics can endure prolonged exposure to sunlight without becoming brittle or degrading. This feature is essential for outdoor applications like lawnmowers or garden equipment.

- 7. Non-Marking: Soft, non-marking plastics are used in applications where floor protection is crucial. These wheels prevent scuffing or damage to delicate flooring surfaces.

- 8. Weight: The choice of material impacts the weight of the wheel. Lighter plastics are preferred for applications where weight reduction is essential, such as aircraft ground support equipment.

- 9. Noise Level: Some plastic materials are designed to reduce noise when in operation. They offer quieter movement, making them suitable for environments where noise reduction is a priority.

- 10. Cost: Material choice can affect the cost of plastic wheels. High-performance plastics often come at a higher price point, while standard plastics like polypropylene are more cost-effective.

The selection of the right plastic material depends on the specific demands of the setting and application. Engineers and manufacturers choose materials that align with the environmental conditions, load requirements, and performance expectations to ensure that plastic wheels deliver optimal results.

How does the choice of plastic wheels affect the overall performance and reliability of rolling systems?

The choice of plastic wheels significantly impacts the overall performance and reliability of rolling systems across various applications. Here’s how the selection of plastic wheels influences these factors:

- 1. Load Capacity: The choice of plastic wheels with the appropriate load capacity is essential. Wheels that can adequately support the intended loads ensure the system’s reliability and prevent premature wear or failure due to overloading.

- 2. Material Selection: Different plastic materials offer varying levels of durability, resistance to environmental factors, and chemical resistance. Selecting the right plastic material for the specific application ensures long-term reliability and performance.

- 3. Smooth Rolling: High-quality plastic wheels with precision bearings offer smooth and consistent rolling motion. This smoothness improves the efficiency and reliability of rolling systems, contributing to reduced wear and lower maintenance requirements.

- 4. Noise Reduction: Plastic wheels are known for their quiet operation due to low friction and noise-dampening properties. Choosing plastic wheels with noise reduction features enhances the comfort and usability of the rolling system, particularly in noise-sensitive environments.

- 5. Floor Protection: Plastic wheels are less likely to damage or mark flooring surfaces compared to metal or rubber wheels. This protection ensures the reliability of indoor rolling systems by preserving the appearance and integrity of floors.

- 6. Resistance to Environmental Factors: Plastic wheels can be selected based on their resistance to environmental conditions, such as moisture, chemicals, and temperature extremes. Choosing wheels with appropriate resistance ensures reliable operation in challenging environments.

- 7. Longevity: High-quality plastic wheels are designed for durability and extended service life. They resist wear and degradation, reducing the frequency of replacements and enhancing the long-term reliability of rolling systems.

- 8. Weight Reduction: Plastic wheels are often lighter than metal alternatives. This weight reduction can improve the efficiency of rolling systems by reducing energy consumption, especially in applications like automotive and aerospace.

- 9. Customization: Plastic wheels can be customized to meet specific requirements, including size, load capacity, and tread design. Customization ensures that the wheels are optimized for the unique needs of the rolling system, enhancing overall performance and reliability.

- 10. Safety: Properly selected plastic wheels provide stability and safety to rolling systems, reducing the risk of accidents, equipment damage, and injuries. Reliability in safety-critical applications is paramount.

In summary, the choice of plastic wheels plays a pivotal role in determining the overall performance and reliability of rolling systems. Factors such as load capacity, material selection, smooth rolling, noise reduction, floor protection, resistance to environmental factors, longevity, weight reduction, customization, and safety considerations all influence the system’s ability to operate efficiently and dependably.

What are the different types and sizes of plastic wheels available in the market?

The market offers a variety of plastic wheels, each designed for specific applications and available in various sizes. Here are different types and sizes of plastic wheels commonly available:

- 1. Caster Wheels: Caster wheels are used for mobility and swiveling in a wide range of applications. They come in sizes ranging from small, furniture casters to large, heavy-duty industrial casters.

- 2. Hand Truck Wheels: These wheels are commonly used on hand trucks and dollies for moving heavy loads. They are available in sizes such as 8-inch, 10-inch, and 12-inch diameters.

- 3. Trolley Wheels: Trolley wheels are used on material handling carts and trolleys. They come in various sizes, including 4-inch, 5-inch, and 6-inch diameters.

- 4. Lawnmower Wheels: These wheels are designed for lawnmowers and other outdoor equipment. They are available in sizes like 8-inch, 10-inch, and 12-inch diameters.

- 5. Office Chair Casters: Office chair casters come in different sizes to fit various chair bases. Common sizes include 2-inch, 2.5-inch, and 3-inch diameters.

- 6. Heavy-Duty Industrial Wheels: These wheels are used in industrial and manufacturing settings. They are available in larger sizes, such as 6 inches, 8 inches, and even up to 12 inches or more in diameter.

- 7. Skateboard Wheels: Plastic skateboard wheels come in various sizes, typically ranging from 50mm to 60mm in diameter, with different hardness levels for different riding styles.

- 8. Conveyor Wheels: Conveyor wheels are used in material handling and conveyor systems. They come in sizes suitable for specific conveyor designs and loads.

- 9. V-Groove Wheels: V-groove wheels are designed for use on tracks or grooves. They come in sizes suitable for different track profiles and load capacities.

- 10. Trailer Jack Wheels: Trailer jack wheels are used for trailer jacks and stabilizers. They come in sizes such as 6-inch, 8-inch, and 10-inch diameters.

- 11. Light-Duty Wheels: These wheels are used in various light-duty applications, such as small carts and furniture. They are available in sizes ranging from 1 inch to 6 inches in diameter.

- 12. Specialized Wheels: Some plastic wheels are designed for specific applications, such as luggage wheels, boat trailer rollers, and gate wheels. Their sizes vary depending on the intended use.

The availability of plastic wheels in different types and sizes allows them to cater to a wide range of industries and applications. When selecting a plastic wheel, it’s essential to consider factors like load capacity, wheel diameter, tread design, and material to ensure it meets the requirements of the specific use case.

editor by Dream 2024-05-08

China wholesaler Plastic Precision Transmission Drive Reduction Cylindrical Involute Duplicate Helical Spur Gear Cog-Wheel

Product Description

Product Description

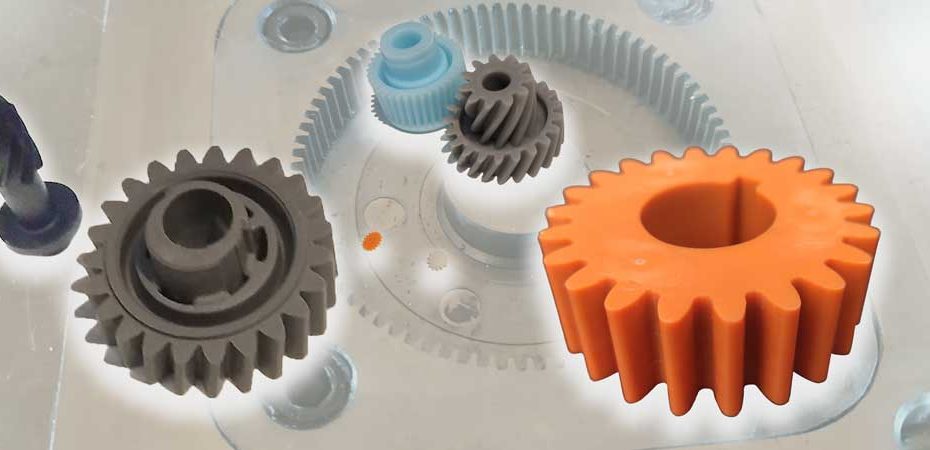

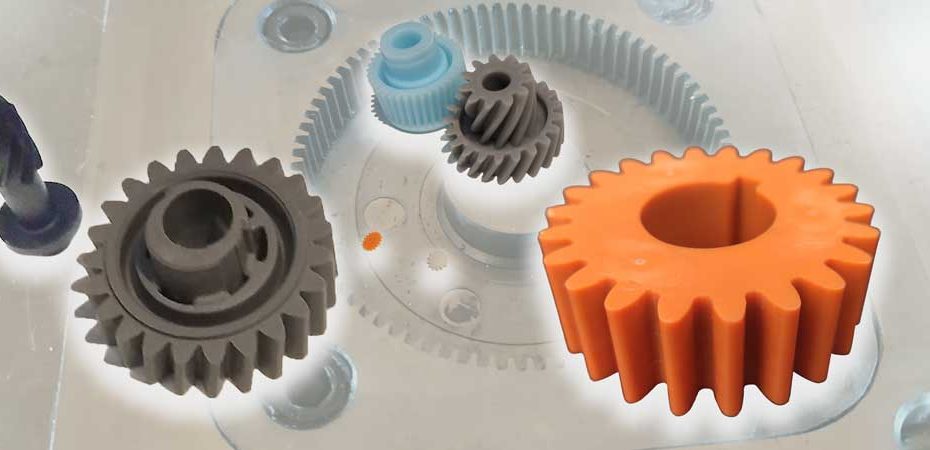

Plastic Precision Transmission Drive reduction cylindrical Involute Duplicate Helical Spur Gear Cog-Wheel

| Item | Customized Injection and machining gears | |

| Process | Injection molding,CNC machining, | |

| material | Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that commonly use plastic wheels?

Plastic wheels are used in a wide range of products and machinery across various industries due to their versatility and unique qualities. Here are examples of products and machinery that commonly use plastic wheels:

- 1. Office Furniture: Office chairs often feature plastic caster wheels for smooth and quiet movement on office floors.

- 2. Material Handling Equipment: Hand trucks, dollies, and carts used in warehouses and distribution centers frequently use plastic wheels to transport goods efficiently.

- 3. Lawn and Garden Equipment: Lawnmowers, garden carts, and wheelbarrows are equipped with plastic wheels for easy maneuverability on lawns and uneven terrain.

- 4. Retail and Shopping Carts: Shopping carts in supermarkets and retail stores typically have plastic wheels for easy navigation through aisles.

- 5. Medical Equipment: Hospital beds, medical carts, and mobility aids often incorporate plastic wheels, as they are easy to clean and resist corrosion.

- 6. Aerospace Ground Support: Ground support equipment at airports, including baggage carts and maintenance vehicles, may use plastic wheels for their lightweight properties.

- 7. Food and Beverage Handling: Food service equipment, such as serving trolleys and food processing machinery, often feature plastic wheels due to their resistance to moisture and corrosion.

- 8. Recreational Vehicles (RVs): RV leveling jacks and stabilizers utilize plastic wheels to provide stability and ease of adjustment when parked.

- 9. DIY and Home Improvement Tools: Hand trucks, utility carts, and toolboxes used for DIY and home improvement projects may have plastic wheels for ease of movement.

- 10. Industrial Machinery: Some industrial machines and equipment incorporate plastic wheels to facilitate movement and protect factory floors.

- 11. Conveyor Systems: Conveyor systems in manufacturing and logistics often use plastic wheels to support the movement of goods along production lines.

- 12. Skateboards and Skateboarding Equipment: Skateboard wheels are typically made of plastic, offering various sizes and hardness levels to suit different riding styles.

- 13. Boat Trailer Rollers: Rollers on boat trailers are commonly made of plastic, as they resist corrosion when exposed to water and provide smooth boat launching and retrieval.

- 14. Gate Hardware: Some gate wheels and sliding door systems feature plastic wheels for smooth operation and reduced noise.

These examples demonstrate the widespread use of plastic wheels in diverse applications, emphasizing their adaptability and suitability for various industries and products.

What considerations should be taken into account when using plastic wheels in different environments?

Using plastic wheels in various environments requires careful consideration of factors to ensure optimal performance and longevity. Here are key considerations when using plastic wheels in different settings:

- 1. Load Capacity: Determine the weight-bearing capacity required for your specific application. Ensure that the plastic wheels you choose can handle the anticipated loads without deformation or failure.

- 2. Material Selection: Select the appropriate plastic material for the environment. Different plastics offer varying levels of resistance to chemicals, moisture, temperature extremes, and UV exposure. Choose a material that aligns with the conditions in which the wheels will operate.

- 3. Temperature Range: Consider the temperature range of the environment. Some plastic materials may become brittle in cold conditions or soften in high heat. Ensure that the selected plastic wheels are suitable for the expected temperature extremes.

- 4. Chemical Exposure: Evaluate whether the wheels will come into contact with chemicals, solvents, or corrosive substances. Choose plastic materials with high chemical resistance to prevent degradation or weakening of the wheels.

- 5. Moisture and Humidity: If the environment is humid or wet, opt for plastic wheels that are moisture-resistant and do not absorb water. This prevents swelling or degradation of the wheels in damp conditions.

- 6. Surface Conditions: Consider the condition of the surfaces the wheels will roll on. Ensure that the flooring or terrain is free from sharp objects, debris, or obstacles that could cause premature wear or damage to the wheels.

- 7. Floor Protection: In indoor environments, choose plastic wheels that do not mark or damage flooring surfaces. Non-marking wheels are essential for preserving the appearance of floors.

- 8. Noise Levels: Assess the noise requirements of the environment. If noise reduction is a priority, select plastic wheels known for their quiet operation, and consider noise-dampening design features.

- 9. Customization: Determine if customization is necessary. Some applications may benefit from wheels with specific tread patterns, sizes, or load ratings. Customization allows you to tailor the wheels to your exact requirements.

- 10. Safety: Prioritize safety considerations, especially in industrial or automotive settings. Ensure that the chosen plastic wheels provide stability and do not compromise safety when handling heavy loads or operating in challenging conditions.

- 11. Maintenance: Plan for regular maintenance and inspections of the wheels based on the environment’s demands. Follow manufacturer guidelines for maintenance practices to extend wheel life and ensure continued functionality.

- 12. Compatibility: Ensure that the plastic wheels are compatible with the equipment or vehicles they will be installed on. Consider factors like wheel size, attachment mechanisms, and load distribution to avoid compatibility issues.

- 13. Regulatory Compliance: In some industries, compliance with specific regulations or standards may be necessary. Ensure that the plastic wheels meet any relevant industry standards or certifications.

By carefully assessing and addressing these considerations, you can make informed decisions when using plastic wheels in diverse environments, optimizing their performance, and ensuring their suitability for the specific conditions they will encounter.

Can you describe the factors to consider when selecting plastic wheels for specific applications?

Selecting the right plastic wheels for specific applications involves considering several crucial factors to ensure optimal performance and durability. Here are the key factors to keep in mind:

- 1. Load Capacity: Determine the weight that the wheels will need to support in your application. Choose wheels with a load capacity that comfortably exceeds the maximum expected load to prevent overloading and premature wear.

- 2. Wheel Diameter: The diameter of the wheel affects its stability, ease of rolling, and ability to overcome obstacles. Select a wheel diameter that suits the terrain and surface conditions in your application.

- 3. Tread Design: Consider the tread pattern on the wheel. Smooth treads offer lower rolling resistance, while treaded or ribbed designs provide better traction. Choose the tread type that aligns with your application’s requirements.

- 4. Material Selection: Plastic wheels are available in various materials, such as polyurethane, polypropylene, and nylon. The choice of material should consider factors like durability, impact resistance, chemical resistance, and temperature resistance based on your application’s environment.

- 5. Bearing Type: Determine the bearing type used in the wheels. Precision bearings, like ball bearings or roller bearings, reduce friction and ensure smooth rolling. Choose bearings appropriate for your application’s load and usage frequency.

- 6. Environment: Assess the operating environment. Consider factors such as exposure to moisture, chemicals, extreme temperatures, and potential corrosion. Select wheels that are suitable for the conditions they will encounter.

- 7. Floor Protection: If your application involves rolling on delicate flooring, consider wheels with softer materials or non-marking properties to protect the floor from damage or marking.

- 8. Mobility and Maneuverability: Evaluate the required mobility and maneuverability of your equipment or vehicle. Swivel casters may be needed for tight spaces, while fixed wheels offer stability in straight-line movement.

- 9. Noise Level: Consider the noise level generated by the wheels. Some applications, like office furniture, require quiet operation. Choose wheels designed to minimize noise if noise is a concern.

- 10. Maintenance: Assess the maintenance requirements of the wheels. Some wheels may require regular lubrication or cleaning, while others are low-maintenance. Ensure that the maintenance demands align with your operational capabilities.

- 11. Mounting and Attachment: Check the compatibility of the wheel’s mounting and attachment method with your equipment or vehicle. The design should securely attach to prevent wobbling or detachment.

- 12. Budget: Consider your budget constraints. Different types of plastic wheels come at various price points. Balance your budget with the need for quality and durability.

By carefully evaluating these factors and selecting plastic wheels that align with your specific application’s requirements, you can ensure that your equipment or vehicle operates optimally, efficiently, and safely.

editor by Dream 2024-05-08

China Professional Custom OEM Machine Drive Injection Plastic Toothed Cylindrical Spur Gear Cog Wheel

Product Description

Product Description

Custom OEM Machine Drive Injection Plastic Toothed Cylindrical Spur Gear Cog Wheel

| Item | Customized Injection and machining gears | |

| Process | Injection molding,CNC machining, | |

| material | Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What maintenance practices are recommended for plastic wheels to ensure optimal functionality?

Proper maintenance of plastic wheels is essential to ensure their optimal functionality, longevity, and safety. Here are recommended maintenance practices for plastic wheels:

- 1. Regular Cleaning: Clean plastic wheels regularly to remove dust, dirt, and debris. Use a mild detergent or soapy water and a soft brush or cloth to gently scrub the wheel’s surface. Rinse thoroughly and allow the wheels to dry completely.

- 2. Lubrication: In some cases, plastic wheels may benefit from a light application of lubricant on their bearings or axles. Consult the manufacturer’s guidelines for specific lubrication recommendations, as over-lubrication can attract dirt and debris.

- 3. Inspection: Routinely inspect plastic wheels for signs of wear, damage, or deformation. Look for cracks, chips, or irregularities in the wheel’s surface. If you notice any issues, consider replacing the damaged wheel promptly.

- 4. Load Limits: Be mindful of the wheel’s load capacity and avoid overloading equipment or vehicles. Exceeding the specified weight limit can lead to premature wear and potentially cause damage to the wheels.

- 5. Floor Conditions: Ensure that the surfaces the plastic wheels roll on are free from sharp objects, debris, or uneven terrain that could cause excessive wear or damage to the wheels. Smooth and clean floors contribute to longer wheel life.

- 6. Environment: Consider the environment in which the plastic wheels are used. Some chemicals or abrasive substances may accelerate wear. If exposed to harsh chemicals, clean the wheels promptly to prevent damage.

- 7. Temperature: Be aware of temperature extremes. Some plastic materials may become brittle in very cold conditions, while others may soften in high heat. Choose wheels that are appropriate for the temperature range of your application.

- 8. Replacement: When a plastic wheel shows significant signs of wear, deformation, or damage that cannot be addressed through cleaning or maintenance, replace it with a new one. Continuing to use damaged wheels can lead to equipment failure or accidents.

- 9. Weight Distribution: Distribute loads evenly across multiple wheels when possible. Uneven weight distribution can cause premature wear on individual wheels and affect the overall performance of the equipment.

- 10. Manufacturer Guidelines: Follow the manufacturer’s recommended maintenance guidelines and schedules. Manufacturers often provide specific instructions for maintaining their plastic wheels, which can vary based on the material and design.

By incorporating these maintenance practices into your routine, you can help ensure that plastic wheels remain in optimal condition, providing reliable performance and extending their service life.

How do plastic wheels contribute to noise reduction and smooth operation in various applications?

Plastic wheels play a significant role in reducing noise and ensuring smooth operation in a wide range of applications across various industries. Their design and material properties contribute to these benefits in the following ways:

- 1. Low Friction: Plastic wheels typically have low friction coefficients when in contact with surfaces. This characteristic minimizes the generation of frictional noise during movement. As a result, plastic wheels roll quietly and smoothly.

- 2. Precision Bearings: Many plastic wheel assemblies feature precision ball bearings or roller bearings. These bearings reduce rotational resistance and provide a smooth, friction-free rotation, further contributing to noise reduction and smooth operation.

- 3. Vibration Dampening: Plastic materials have natural vibration-dampening properties. When used in wheels, they can absorb and dissipate vibrations caused by uneven surfaces, reducing the transmission of vibration-related noise to the surroundings.

- 4. Floor Protection: Plastic wheels are gentle on flooring surfaces. They do not scuff, scratch, or mark floors, which is essential in applications where floor protection and aesthetics are important, such as in homes, offices, and healthcare facilities.

- 5. Absence of Metal-to-Metal Contact: Unlike metal wheels, plastic wheels do not produce noise through metal-to-metal contact with surfaces. This lack of contact noise makes plastic wheels quieter and more suitable for noise-sensitive environments.

- 6. Lightweight Construction: Plastic wheels are often lighter than metal alternatives. Their reduced weight places less stress on equipment, resulting in less noise generated by impacts or vibrations when wheels encounter obstacles or uneven terrain.

- 7. Non-Marking Materials: Some plastic wheels are designed with non-marking materials that prevent them from leaving marks or streaks on floors. This feature is valuable in applications where maintaining a clean and unblemished appearance is a priority.

- 8. Custom Tread Design: Plastic wheels can have customized tread patterns that optimize grip and reduce noise. Treads with unique designs can minimize rolling resistance, improve traction, and contribute to quieter operation.

- 9. Moisture Resistance: Plastic wheels do not absorb moisture, which can affect the performance of certain materials like rubber. This moisture resistance ensures consistent operation even in damp conditions.

- 10. Versatility: Plastic wheels are versatile and can be tailored to specific applications. By selecting the right plastic material, bearing type, and tread design, manufacturers can optimize plastic wheels for noise reduction and smooth operation in a variety of settings.

Overall, the noise reduction and smooth operation provided by plastic wheels make them suitable for applications where minimizing noise pollution, ensuring comfort, and maintaining floor integrity are essential considerations.

How does the design of a plastic wheel contribute to its durability and performance?

The design of a plastic wheel plays a significant role in determining its durability and performance. Several key design factors contribute to these attributes:

- 1. Material Selection: The choice of plastic material is crucial. High-quality plastics, such as polyurethane, polypropylene, and nylon, are commonly used for wheel construction. These materials offer excellent durability, impact resistance, and resistance to wear and tear.

- 2. Load Capacity: The design of the wheel must consider the expected load capacity. Reinforcements, such as ribbing or internal structures, can be added to strengthen the wheel and enhance its load-bearing capabilities. Proper load capacity design ensures that the wheel can support the intended weight without deformation or failure.

- 3. Bearing Type: The design of the wheel includes the type of bearing used. Precision bearings, such as ball bearings or roller bearings, reduce friction and ensure smooth rolling. Properly designed bearings enhance the wheel’s performance by reducing resistance and minimizing wear.

- 4. Tread Design: The tread design on the wheel affects its grip, stability, and noise level. Different tread patterns are used for specific applications. For example, smooth treads provide reduced rolling resistance, while treaded designs offer improved traction. The choice of tread design depends on the intended use.

- 5. Hub and Axle Compatibility: The design of the wheel’s hub and axle connection is essential for secure attachment. It should be compatible with the mounting hardware used in the application. A well-designed hub and axle connection ensure stability and prevent wobbling or detachment during use.

- 6. Resilience: The design should consider the wheel’s ability to absorb shocks and impacts. Resilient plastic materials can withstand sudden impacts without cracking or breaking. This is especially important in applications where the wheel may encounter rough terrain or obstacles.

- 7. Temperature Resistance: Depending on the application, plastic wheels may need to withstand a wide range of temperatures. The design should factor in the material’s temperature resistance to ensure that the wheel remains functional in extreme conditions.

- 8. Size and Dimensions: The size and dimensions of the wheel are critical for load distribution and stability. Properly sizing the wheel according to the application’s requirements ensures optimal performance and durability.

- 9. Corrosion Resistance: In some environments, corrosion resistance is essential. The design may incorporate materials or coatings that protect against corrosion, ensuring a longer service life.

- 10. Wheel Mounting: The method of mounting the wheel to the equipment or vehicle is part of the design. It should be secure and reliable to prevent wobbling or detachment during use.

- 11. Weight Distribution: Proper weight distribution across the wheel is important for even wear and reduced stress on the wheel. Design considerations may include the wheel’s shape and load-bearing capacity to ensure even weight distribution.

A well-designed plastic wheel takes into account these factors to maximize its durability and performance. It should be capable of withstanding the demands of its intended application while providing smooth and reliable movement.

editor by Dream 2024-05-06

China Professional Custom OEM Involute Spline Machine Drive Spur Plastic Precision Gear Cog Wheel

Product Description

Product Description

Custom OEM Involute Spline Machine Drive Spur Plastic Precision Gear Cog Wheel

| Item | Customized Injection and machining gears | |

| Process | Injection molding,CNC machining, | |

| material | Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do plastic wheels fare in terms of weight-bearing capacity compared to other materials?

Plastic wheels have weight-bearing capacity that varies depending on factors such as the type of plastic used and the wheel’s design. Compared to other materials like metal, here’s how plastic wheels generally fare in terms of weight-bearing capacity:

- 1. Light to Medium Loads: Plastic wheels are well-suited for light to medium loads. They can typically support loads ranging from a few pounds up to several hundred pounds, depending on their design and construction. For applications such as office chairs, hand trucks, and smaller carts, plastic wheels are often sufficient.

- 2. Heavy-Duty Loads: When it comes to heavy-duty loads, metal wheels, particularly steel and cast iron wheels, are preferred. Metal wheels can handle much heavier loads compared to plastic wheels. In industrial settings, where loads can exceed a thousand pounds or more, metal wheels provide the necessary strength and durability.

- 3. Load Distribution: Plastic wheels may perform well in load distribution when used in sets or pairs. Distributing the load across multiple plastic wheels can increase their effective weight-bearing capacity. However, metal wheels still excel in heavy load-bearing scenarios.

- 4. Reinforced Plastic Wheels: Some plastic wheels are designed with reinforced materials, internal structures, or additional support to enhance their weight-bearing capacity. These reinforced plastic wheels can handle heavier loads than standard plastic wheels but may not match the load capacity of metal wheels.

- 5. Material and Design: The choice of plastic material and the wheel’s design significantly impact its load capacity. High-quality plastics like nylon and polyurethane tend to have better load-bearing capabilities compared to softer plastics like polypropylene. Additionally, factors such as wheel diameter and tread design play a role in load-bearing capacity.

- 6. Application Considerations: The suitability of plastic wheels for weight-bearing also depends on the specific application. For applications where load capacity is a critical factor, such as heavy machinery or industrial equipment, metal wheels are typically chosen to ensure safety and reliability.

In summary, plastic wheels are suitable for light to medium loads in various applications. They offer benefits such as corrosion resistance, quiet operation, and floor protection. However, for heavy-duty applications with substantial loads, metal wheels, particularly steel and cast iron wheels, are preferred due to their superior weight-bearing capacity and durability.

How does the choice of plastic wheels affect the overall performance and reliability of rolling systems?

The choice of plastic wheels significantly impacts the overall performance and reliability of rolling systems across various applications. Here’s how the selection of plastic wheels influences these factors:

- 1. Load Capacity: The choice of plastic wheels with the appropriate load capacity is essential. Wheels that can adequately support the intended loads ensure the system’s reliability and prevent premature wear or failure due to overloading.

- 2. Material Selection: Different plastic materials offer varying levels of durability, resistance to environmental factors, and chemical resistance. Selecting the right plastic material for the specific application ensures long-term reliability and performance.

- 3. Smooth Rolling: High-quality plastic wheels with precision bearings offer smooth and consistent rolling motion. This smoothness improves the efficiency and reliability of rolling systems, contributing to reduced wear and lower maintenance requirements.

- 4. Noise Reduction: Plastic wheels are known for their quiet operation due to low friction and noise-dampening properties. Choosing plastic wheels with noise reduction features enhances the comfort and usability of the rolling system, particularly in noise-sensitive environments.

- 5. Floor Protection: Plastic wheels are less likely to damage or mark flooring surfaces compared to metal or rubber wheels. This protection ensures the reliability of indoor rolling systems by preserving the appearance and integrity of floors.

- 6. Resistance to Environmental Factors: Plastic wheels can be selected based on their resistance to environmental conditions, such as moisture, chemicals, and temperature extremes. Choosing wheels with appropriate resistance ensures reliable operation in challenging environments.

- 7. Longevity: High-quality plastic wheels are designed for durability and extended service life. They resist wear and degradation, reducing the frequency of replacements and enhancing the long-term reliability of rolling systems.

- 8. Weight Reduction: Plastic wheels are often lighter than metal alternatives. This weight reduction can improve the efficiency of rolling systems by reducing energy consumption, especially in applications like automotive and aerospace.

- 9. Customization: Plastic wheels can be customized to meet specific requirements, including size, load capacity, and tread design. Customization ensures that the wheels are optimized for the unique needs of the rolling system, enhancing overall performance and reliability.

- 10. Safety: Properly selected plastic wheels provide stability and safety to rolling systems, reducing the risk of accidents, equipment damage, and injuries. Reliability in safety-critical applications is paramount.

In summary, the choice of plastic wheels plays a pivotal role in determining the overall performance and reliability of rolling systems. Factors such as load capacity, material selection, smooth rolling, noise reduction, floor protection, resistance to environmental factors, longevity, weight reduction, customization, and safety considerations all influence the system’s ability to operate efficiently and dependably.

Can you describe the factors to consider when selecting plastic wheels for specific applications?

Selecting the right plastic wheels for specific applications involves considering several crucial factors to ensure optimal performance and durability. Here are the key factors to keep in mind:

- 1. Load Capacity: Determine the weight that the wheels will need to support in your application. Choose wheels with a load capacity that comfortably exceeds the maximum expected load to prevent overloading and premature wear.

- 2. Wheel Diameter: The diameter of the wheel affects its stability, ease of rolling, and ability to overcome obstacles. Select a wheel diameter that suits the terrain and surface conditions in your application.

- 3. Tread Design: Consider the tread pattern on the wheel. Smooth treads offer lower rolling resistance, while treaded or ribbed designs provide better traction. Choose the tread type that aligns with your application’s requirements.

- 4. Material Selection: Plastic wheels are available in various materials, such as polyurethane, polypropylene, and nylon. The choice of material should consider factors like durability, impact resistance, chemical resistance, and temperature resistance based on your application’s environment.

- 5. Bearing Type: Determine the bearing type used in the wheels. Precision bearings, like ball bearings or roller bearings, reduce friction and ensure smooth rolling. Choose bearings appropriate for your application’s load and usage frequency.

- 6. Environment: Assess the operating environment. Consider factors such as exposure to moisture, chemicals, extreme temperatures, and potential corrosion. Select wheels that are suitable for the conditions they will encounter.

- 7. Floor Protection: If your application involves rolling on delicate flooring, consider wheels with softer materials or non-marking properties to protect the floor from damage or marking.

- 8. Mobility and Maneuverability: Evaluate the required mobility and maneuverability of your equipment or vehicle. Swivel casters may be needed for tight spaces, while fixed wheels offer stability in straight-line movement.

- 9. Noise Level: Consider the noise level generated by the wheels. Some applications, like office furniture, require quiet operation. Choose wheels designed to minimize noise if noise is a concern.

- 10. Maintenance: Assess the maintenance requirements of the wheels. Some wheels may require regular lubrication or cleaning, while others are low-maintenance. Ensure that the maintenance demands align with your operational capabilities.

- 11. Mounting and Attachment: Check the compatibility of the wheel’s mounting and attachment method with your equipment or vehicle. The design should securely attach to prevent wobbling or detachment.

- 12. Budget: Consider your budget constraints. Different types of plastic wheels come at various price points. Balance your budget with the need for quality and durability.

By carefully evaluating these factors and selecting plastic wheels that align with your specific application’s requirements, you can ensure that your equipment or vehicle operates optimally, efficiently, and safely.

editor by Dream 2024-04-25

China supplier Machine Drive Plastic Custom Toothed Nylon Cylindrical Straight Spur Gear Cog Wheel

Product Description

Product Description

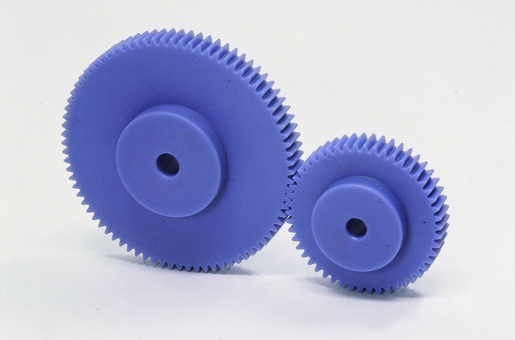

Machine Drive Plastic Custom Toothed nylon Cylindrical Straight Spur Gear Cog Wheel

| Item | Customized Injection and machining gears | |

| Process | Injection molding,CNC machining, | |

| material | Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?