Product Description

ACE offers plastic turnkey answer from innovative principle layout to actuality. ACE is CZPT to meet up with our customer’s Most difficult requires by way of the merged use of worldwide condition-of-the-artwork gear and conventional Tool-making expertise. ACE group designers and toolmakers with collective encounter continually strive to Refine and perfect our expertise. Our leading performance is foundation on the profitable execution of each and every single step.

“Proper at the very first time”.,

* Plastic processing with Medium and large processing home windows

* For all thermoplastics which includes Filler and reinforcing supplies

Our Providers

ACE Injection Mold & Molding Team is a privately owned firm specializing in the layout and manufacture of higher-quality plastic injection molds and injection molded areas for the global marketplace and Have been engaged in the manufacturing sector given that our inception.Is an OEM/ODM factory, customized your merchandise to meet your wants is our benefit, We are managed by a group of specialists with a lot of years of encounter in mildew design and style, molding technological innovation and High quality control. We have designed an exceptional comprehension of the specialized and top quality specifications needed.

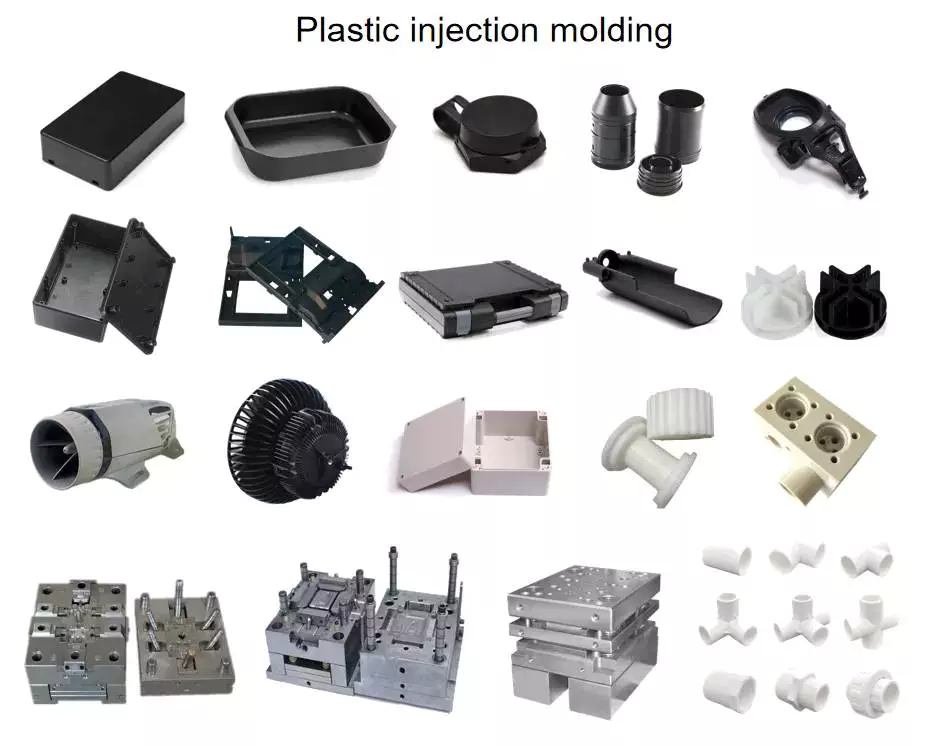

We develop resources to in shape your expectations and match your quality standards.Our staff of CAD designers will make sure that your creativeness is included into the real solution!If you want to create prototype or mass-produce in a very certain task, we can help you accomplish your eyesight!Our items incorporate :

*Personalized Plastic Parts

*Multi-cavity plastic areas

*High Precision Molds

*Insert & over moulding

*Double Short Moulding

*Unscrewing Moulding

*Gas-assisted Moulding

*Die Casting Moulding

*Prototype plastic parts and Reduced cycle plastic components moulding

*Gasoline Aid moulding

*Elastomeric moulding

*IML & IMD portion creation

*Slender wall plastic moulding

*Substantial temperature moulding

*Foam Injection moulding

Why Pick Us

1. We have our possess design and style and advancement team and manufacturing facility, with far more than 15 many years of product generation knowledge. Familiar with and great at building business with abroad industry.

2. We can provide OEM/ODM services for all types of consumers, and our skilled help staff will supply providers for buyers 24 several hours a day.

3. We have a very robust good quality handle program to make certain the best good quality of our items, the very best service and aggressive price tag.

4. Samples are constantly accessible for good quality inspection and can be sent to you extremely quickly.

5. Layout capability: layout according to consumer specifications.

6. We supply products on time and cooperate with customers sincerely.

Good quality Management

Inspection Method

We will provide entirely dimension examining just before Formal manufacturing.

Make sure all components dimension under appropriate tolerance.

We determine top quality as complete consumer fulfillment. This drives us to settle for nothing much less than for CZPT in all aspects of our company as we continuously enhance our strong compliment of our employees and procedures.

Organization Profile

We are managed by a group of experts with several a long time of encounter in CZPT design and style, molding engineering and high quality handle. Our clientele are CZPT to communicate with us freely in English, Japanese ,German and US, Considering that we build exclusively for the intercontinental market, mainly Europe, Japan & North America, we have created an excellent comprehending of the complex and high quality needs necessary.

Capacity – Equipment listingTolerance* Mold: .005mm

* Plastic part: .01m

|

ACE Mildew & MOULDING Equipment & Push Checklist 2571 |

|||||

|

Office |

Significant Tools |

Identify |

Specification |

Device |

Overall |

|

Mold Office |

CNC Machining Center |

ROEDERS RFM-800 Precision Centre Manufactured in Germany |

36000/min |

2 |

15 |

|

ROEDERS RXP-500 Precision Centre with Renishaw on-line inspection Produced in Germany |

50000/min |

2 |

|||

|

ROEDERS RFM-600 Precision Centre with Renishaw on the internet inspection Manufactured in Germany |

42000/min |

two |

|||

|

ROEDERS RFM-600 Precision Centre Made in Germany |

42000/min |

2 |

|||

|

KT-600II Precision Centre |

24000/min |

three |

|||

| Priminer V2013HS Size:2000*1300*800mm | 20000/min | 1 | |||

| FANUC α-D14MiA | 30000/min | 1 | |||

|

Shenghong ZheJiang |

8500/min |

2 |

|||

|

Electrical Discharge Device(EDM) |

SODICK EDM Machine |

AD30L |

four |

12 |

|

|

MAKINO |

EDGE3 |

two |

|||

| EDGE2 | 2 | ||||

|

Wintop |

350 |

2 |

|||

|

Wintop |

DE -650 |

two |

|||

|

Milling Machine |

Milling equipment |

16SS |

eight |

nine |

|

|

Mazak |

Milling device |

QTN150 |

one |

||

| Wire reduce equipment | Sodick ALN 600Gs | 0.002mm |

one |

5 | |

| Sodick ALN 400Gs | 0.002mm | 1 | |||

| MV1200S | 0.005mm | 3 | |||

| Fitting device | ShunXing | Max:100Ton | 1 | 1 | |

| Grind device | Kent KGS-7132AH | Size:1000*350mm | 1 | 6 | |

| Xiangyu EM618 | Size:400*270*200mm | 5 | |||

|

Drill Press Machine |

Drill Press device |

Z3032X10 |

one |

one |

|

|

Molding Office |

Plastic injection equipment |

Injection equipment |

Fanuc-CX250 |

10 |

31 |

|

Kiaming 98T |

one |

||||

|

Kaiming128T |

two |

||||

|

Kaiming 168 T |

2 |

||||

|

HaiTian 200T |

8 |

||||

|

ZheJiang 250T |

1 |

||||

|

Toshiba 220T |

1 |

||||

|

Kaiming 400T |

2 |

||||

|

Kaiming 450T |

one |

||||

|

HaiTian 650T |

two |

||||

|

HaiTian 1300T |

one |

||||

|

High quality Department |

Inspection equipment |

2.5D Online video Measuring Program |

VMS-2015F |

1 |

3 |

|

Alberlink CMM |

HR-150A |

two |

|||

Firm

Currently have a strong crew with 140 individuals, including

*32 Design & Engineers ( ≥ ten years’ experience)

*12 CNC programmers

*8 Venture engineers

*6 Product sales men and women

*5 Total-time quality inspection personnel

*4 Folks in logistic team

*60 Instrument makers

*14 Office employee

Workshop/Packaging&Shipping

Our factory is underneath ISO requirements & certification.This insures efficiency and total handle on high quality.

Our standard packaging for plastic injection parts we use PP bag in addition cardboard packing containers or as for every buyer needs.

Our standard packaging for plastic injection mildew is picket pallets or wood situations.

Other Items

Our website lists some of our successful items, but please observe that this is just 1 illustration on behalf of our merchandise and solutions, so if you cannot see the products you want, remember to get in touch with us right away. We warmly welcome buyers all in excess of the world and are searching ahead to establishing a regular and prolonged-phrase business connection with you. Professional plastic injection mold and plastic goods / plastic injection moulding manufacturing facility.

FAQ

Q: What services do you give?

A: We manufacture plastic injection molds and produce plastic injection components for sampling and bulk generation.We also provide mold design and style solutions.

Q: How can I contact you?

A: You can deliver us an inquiry by means of electronic mail, Created-in-china TradeMessenger, WhatsApp, Skype or Wechat. We will reply to you in 24 hours.

Q: How can I get a quotation?

A:Soon after receving your RFQ, we will reply to you within 2 hours. In your RFQ, remember to offer the adhering to details and info in purchase for us to ship you competitive pricing primarily based on your specifications.a) 2d component drawings in PDF or JPG structure & 3D part drawings in UG, Professional/E, SOLIDWORKS, CATIA, CAD, STP, X_T, IGS, PRT, DWG, or DXFb) Resin details (Datasheet) Yearly quantity prerequisite for plastic components.

Q: What shall we do if we don’t have portion drawings?

A: You can ship us your plastic element samples or images with proportions and we could give you our complex options. We will develop .

Q: Can we get some samples just before mass manufacturing?

A: Indeed, we will deliver you samples for confirmation before commence of mass manufacturing.

Q: Because of to time variation with China and overseas, how can I get information about my purchase development?

A: Each and every week we send out weekly creation progress report with digital pictures and movies that shows the creation progress.

Q: What is your leadtime?

A: Our regular leadtime for mould manufacturing is four months.For plastic elements is 4-twenty days based on the quantity.

Q: What is your payment time period?

A: 50% as payment deposit, fifty% balance will be paid out before transport. For little quantity, we acknowledge Paypal, Paypal commission will be included to the order. For massive volume, T/T is desired.

Q: How do you deliver the merchandise?

A: We have our personal logistics department that could give shipping and delivery fees via Sea or Air freight, Incoterms EXW, FOB, CIF,DDP, DDU and so on. Or we can operate with your appointed shipping and delivery forwarder.

Q: How can I guarantee our high quality?

A: In the course of mildew generating, we do substance and component inspection. Throughout component manufacturing, we do a hundred% full quality inspection before packaging and reject every single areas that is not according to our good quality normal or the high quality approved by our consumer.

|

US $0.01-1 / Piece | |

1,000 Pieces (Min. Order) |

###

| Plastic Type: | Thermosetting Plastic |

|---|---|

| Plastic Form: | Granule |

| Molding Method: | Injection Molding |

| Tolerance Request: | up to (±0.01mm) |

| Material: | ABS, PA, PC, PE, PP, PS, PVC, POM etc |

| Machine Tonnage: | 90t-1200t |

###

| Customization: |

Available

|

|---|

###

|

ACE MOLD & MOULDING EQUIPMENT & PRESS LIST 2022

|

|||||

|

Department

|

Major Equipment

|

Name

|

Specification

|

Unit

|

Total

|

|

Mold Department

|

CNC Machining Center

|

ROEDERS RFM-800 Precision Centre Made in Germany

|

36000/min

|

2

|

15

|

|

ROEDERS RXP-500 Precision Centre with Renishaw online inspection Made in Germany

|

50000/min

|

2

|

|||

|

ROEDERS RFM-600 Precision Centre with Renishaw online inspection Made in Germany

|

42000/min

|

2

|

|||

|

ROEDERS RFM-600 Precision Centre Made in Germany

|

42000/min

|

2

|

|||

|

KT-600II Precision Centre

|

24000/min

|

3

|

|||

| Priminer V2013HS Size:2000*1300*800mm | 20000/min | 1 | |||

| FANUC α-D14MiA | 30000/min | 1 | |||

|

Shenghong taiwan

|

8500/min

|

2

|

|||

|

Electric Discharge Machine(EDM)

|

SODICK EDM Machine

|

AD30L

|

4

|

12

|

|

|

MAKINO

|

EDGE3

|

2

|

|||

| EDGE2 | 2 | ||||

|

Wintop

|

350

|

2

|

|||

|

Wintop

|

DE -650

|

2

|

|||

|

Milling Machine

|

Milling machine

|

16SS

|

8

|

9

|

|

|

Mazak

|

Milling machine

|

QTN150

|

1

|

||

| Wire cut machine | Sodick ALN 600Gs | 0.002mm |

1

|

5 | |

| Sodick ALN 400Gs | 0.002mm | 1 | |||

| MV1200S | 0.005mm | 3 | |||

| Fitting machine | ShunXing | Max:100Ton | 1 | 1 | |

| Grind machine | Kent KGS-7132AH | Size:1000*350mm | 1 | 6 | |

| Xiangyu EM618 | Size:400*270*200mm | 5 | |||

|

Drill Press Machine

|

Drill Press machine

|

Z3032X10

|

1

|

1

|

|

|

Molding Department

|

Plastic injection machine

|

Injection machine

|

Fanuc-CX250

|

10

|

31

|

|

Kiaming 98T

|

1

|

||||

|

Kaiming128T

|

2

|

||||

|

Kaiming 168 T

|

2

|

||||

|

HaiTian 200T

|

8

|

||||

|

Taiwan 250T

|

1

|

||||

|

Toshiba 220T

|

1

|

||||

|

Kaiming 400T

|

2

|

||||

|

Kaiming 450T

|

1

|

||||

|

HaiTian 650T

|

2

|

||||

|

HaiTian 1300T

|

1

|

||||

|

Quality Department

|

Inspection machine

|

2.5D Video Measuring System

|

VMS-2015F

|

1

|

3 |

|

Alberlink CMM

|

HR-150A

|

2

|

|||

|

US $0.01-1 / Piece | |

1,000 Pieces (Min. Order) |

###

| Plastic Type: | Thermosetting Plastic |

|---|---|

| Plastic Form: | Granule |

| Molding Method: | Injection Molding |

| Tolerance Request: | up to (±0.01mm) |

| Material: | ABS, PA, PC, PE, PP, PS, PVC, POM etc |

| Machine Tonnage: | 90t-1200t |

###

| Customization: |

Available

|

|---|

###

|

ACE MOLD & MOULDING EQUIPMENT & PRESS LIST 2022

|

|||||

|

Department

|

Major Equipment

|

Name

|

Specification

|

Unit

|

Total

|

|

Mold Department

|

CNC Machining Center

|

ROEDERS RFM-800 Precision Centre Made in Germany

|

36000/min

|

2

|

15

|

|

ROEDERS RXP-500 Precision Centre with Renishaw online inspection Made in Germany

|

50000/min

|

2

|

|||

|

ROEDERS RFM-600 Precision Centre with Renishaw online inspection Made in Germany

|

42000/min

|

2

|

|||

|

ROEDERS RFM-600 Precision Centre Made in Germany

|

42000/min

|

2

|

|||

|

KT-600II Precision Centre

|

24000/min

|

3

|

|||

| Priminer V2013HS Size:2000*1300*800mm | 20000/min | 1 | |||

| FANUC α-D14MiA | 30000/min | 1 | |||

|

Shenghong taiwan

|

8500/min

|

2

|

|||

|

Electric Discharge Machine(EDM)

|

SODICK EDM Machine

|

AD30L

|

4

|

12

|

|

|

MAKINO

|

EDGE3

|

2

|

|||

| EDGE2 | 2 | ||||

|

Wintop

|

350

|

2

|

|||

|

Wintop

|

DE -650

|

2

|

|||

|

Milling Machine

|

Milling machine

|

16SS

|

8

|

9

|

|

|

Mazak

|

Milling machine

|

QTN150

|

1

|

||

| Wire cut machine | Sodick ALN 600Gs | 0.002mm |

1

|

5 | |

| Sodick ALN 400Gs | 0.002mm | 1 | |||

| MV1200S | 0.005mm | 3 | |||

| Fitting machine | ShunXing | Max:100Ton | 1 | 1 | |

| Grind machine | Kent KGS-7132AH | Size:1000*350mm | 1 | 6 | |

| Xiangyu EM618 | Size:400*270*200mm | 5 | |||

|

Drill Press Machine

|

Drill Press machine

|

Z3032X10

|

1

|

1

|

|

|

Molding Department

|

Plastic injection machine

|

Injection machine

|

Fanuc-CX250

|

10

|

31

|

|

Kiaming 98T

|

1

|

||||

|

Kaiming128T

|

2

|

||||

|

Kaiming 168 T

|

2

|

||||

|

HaiTian 200T

|

8

|

||||

|

Taiwan 250T

|

1

|

||||

|

Toshiba 220T

|

1

|

||||

|

Kaiming 400T

|

2

|

||||

|

Kaiming 450T

|

1

|

||||

|

HaiTian 650T

|

2

|

||||

|

HaiTian 1300T

|

1

|

||||

|

Quality Department

|

Inspection machine

|

2.5D Video Measuring System

|

VMS-2015F

|

1

|

3 |

|

Alberlink CMM

|

HR-150A

|

2

|

|||

Design Considerations for Injection Molded Parts

There are many factors to consider when designing a component for injection molding. These include design factors, materials, overhangs, and process. Understanding these factors will make it easier to choose the right part for the application. In this article, we’ll go over several of the most common design considerations.

Design factors

To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools.

To get the best results from your injection molded parts, you must ensure that they meet certain design factors. These factors can help you achieve consistent parts and reduce cost. These guidelines can also help you to avoid common defects. One of the most common defects is warping, which is caused by the unintended warping of the part as it cools.

When designing injection molded parts, the draft angle is critical. Increasing the draft angle allows the part to emerge cleanly from the mold and reduces stress concentration. This can improve the part’s function and speed up the production process. In addition, it ensures a uniform surface finish. Incorrect draft angles can result in parts that are not functional and can cost you money. If your product team doesn’t pay attention to these design factors, they could end up destroying expensive molds and producing a high number of rejects.

Ribs are another design factor that should be taken into consideration. Rib height should be less than three times the thickness of the part’s wall. This will prevent sink marks and minimize the chances of the ribs sticking inside the mold.

Materials

There are many options when it comes to materials for injection molded parts. Choosing the right material will affect how well it performs in your particular application. If you need a large part to be flexible and sturdy, then a plastic with good flow properties will work best. Injection molded plastics come in a variety of different resins. Choose the one that best meets your application’s needs, considering its main functionality and the desired appearance. You may also want to choose a material that is UV resistant, heat resistant, flexible, and food safe.

Polymers that are suitable for injection molding include polycarbonate and polypropylene. These materials are flexible and strong, and can be used to create parts with high-level details. These materials are also lightweight and inexpensive. Despite being flexible, they are not suitable for high-stress applications.

During the molding process, the injected material must be cooled, otherwise it will expand again. This is why you need to keep the temperature of the mould at 80 degrees Celsius or less.

Process

Injection molding is the process of creating plastic parts. The plastic is melted in a mold and then forced to cool. It then solidifies into the desired shape. During the cooling process, the plastic can shrink, so it is important to pack the material tightly in the mold to prevent visible shrinkage. When the mold is completed, it cannot be opened until the required cooling time has passed. This time can be estimated based on the thermodynamic properties of plastic and the maximum wall thickness of the part.

The mold must be precisely designed and tested. The process can be repeated many times, which makes it ideal for mass production. It is also one of the fastest ways to scale production. The more parts a mold can produce, the lower its cost per piece. This is one of the benefits of injection molding.

Injection molding parts are used for many industries, including appliances, electronics, packaging, and medical devices. They can be made to have complicated shapes.

Overhangs

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

Overhangs are areas of extra material that surround the surface of an injection molded part. This extra material is typically made of inexpensive material that is edged or glued on the part’s surface. The overhang material can be easily separated from the blank using a simple cutting process.

The amount of material needed for an overhang is dependent on the shape of the part and the amount of surface area. Generally, an overhang is less than 15 percent of the cost of the part. Usually, the material used should be able to fulfill the overhang’s function and differentiate it from the material in the form flachen area.

Overhangs on injection molded parts should be avoided because they may cause the design to become unstable. To avoid this problem, consider designing your part so that the sides and edges are parallel to one another. This will help ensure that the part will be free of undercuts and overhangs.

Overhangs on injection molded parts can be avoided by ensuring that the parts are designed with tolerances in mind. For example, an overhang in an injection molded part can cause a mold to have an overhang that is too small for the machine. This can cause problems in the manufacturing process, and it can result in a costly mold.

Cost

Injection molding costs can vary depending on the complexity of the part, the size and the type of plastic. Parts with complex geometries may require additional design work and tooling. Larger parts can also cost more than small ones. The amount of time spent designing and producing them is also important.

To reduce the cost of injection molding, a manufacturer must consider two major factors: tooling and the material used. The plastic used for injection molding has several different properties, which will impact the part price. For instance, plastics with a lot of glass fibers will reduce the amount of time necessary to repair the mold. Another factor to consider is the thermal properties of the material.

The next major factor in the cost of injection molded parts is the material of the injection mold. While most of these molds are made of steel, the type and grade of steel used is important. Injection molds are also required to have nearly wear-free interior cavities. This is necessary to maintain tight tolerances.

Another factor that contributes to the cost of injection molded parts is the cost of bulk material. This material costs money and requires expensive electricity to process. Typically, the more parts you produce, the lower the cost per pound. Storage of bulk material is also a significant expense. Therefore, a quicker cycle time will reduce storage costs.

Reliability

While manufacturing involves some degree of variation, the variation should be within acceptable limits. This is essential if you want to produce high-quality, dimensionally stable parts. A reliable manufacturing process involves precise control over mold tooling and part design. It also requires repeatability in both quality and production processes.

A reliable injection molding process also focuses on detecting defects early in the production process. Invisible hazards, such as air pockets, mold materials compromised by overheating, and more, can lead to failure. These defects will most likely not be discovered by simple visual inspection and may not come to light until after warranty claims are filed from the field. By finding the defects in the early stages, manufacturers can maximize productivity and reduce costs by minimizing the number of replacement parts needed.

The process of building a custom mould for plastic components is highly skilled. A perfect mould will eliminate potential defects and ensure that the production process is reliable. Traditionally, this process relied on trial and error, which added time and money to the production process.

Design for manufacturability

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

When designing injection molded parts, it is imperative to keep in mind their manufacturability. Injection molding allows for complex geometries and multiple functions to be combined into a single part. For example, a hinged part can have a single mold that can produce two different halves. This also decreases the overall volume of the part.

Injection molded parts do not typically undergo post-processing. However, the mold itself can be finished to various degrees. If the mold is rough, it can cause friction during the ejection process and require a larger draft angle. Detailed finishing procedures are outlined by the Society of Plastics Industry.

The process of designing injection molds is very exacting. Any errors in the mold design can lead to out-of-spec parts and costly repair. Therefore, the process of Design for Manufacturability (DFM) validation is a key step early in the injection molding process. Fictiv’s DFM feedback process can identify design challenges and provide early feedback to minimize lead times and improve quality.

The surface of an injection molded part can develop sink marks, which occur when the material has not fully solidified when it is ejected from the mold. Parts with thick walls or ribs are more prone to sinking. Another common defect in plastic injection molding is drag marks, which occur when walls scrape against one another during ejection. In addition to sink marks, parts with holes or exposed edges can form knit lines.

editor by czh 2022-12-17