Product Description

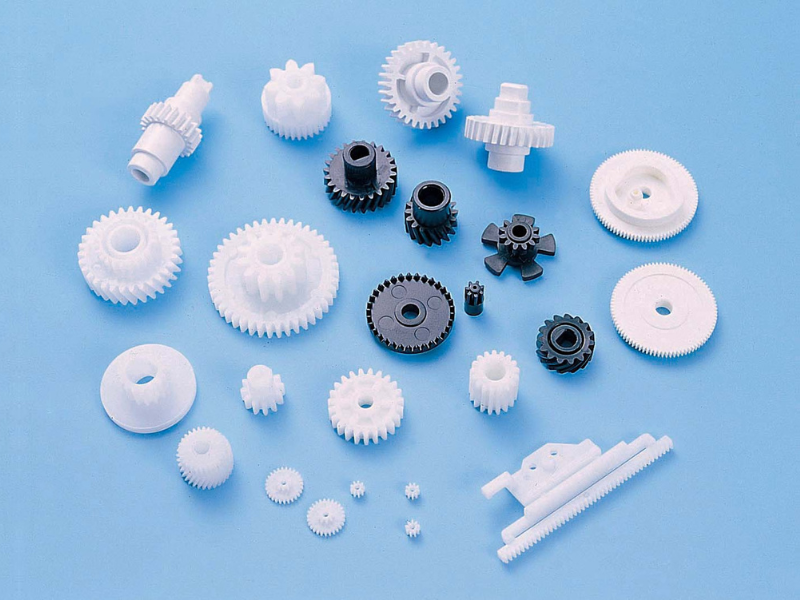

Detailed Photos

Product Description

| Item No. | Plastic Nylon Screw Bearing Pulley |

| Dimensions | OEM ODM |

| Material | Bearing -Chrome steel, carbon steel, stainless steel Plastic part- POM/ Nylon6 /Nylon66 +GF/PU/Rubber Housing part – Plastic(Nylon)/ Steel/ Zinc alloy die casting / Aluminium profile/ alu. Alloy die casting |

| Color | Original/black/white/Red/ Green/ Orange, or per customers’ requirement |

| Surface Treatment | Zinc plated/Nickle Plated/Black treatment/ Painting/Electrophoretic treatment |

| Features | heavy-duty,adjustable,low noise,easy installation,sliding smoothly,long life,standard,customized,etc. |

| Application | Sliding window and door, Sliding accessories, furniture accessories etc. |

| Packaing | Foil bag+Neutral Carton+Pallet, or per customers’ requirement |

| MOQ | 1000 pcs |

| Lead Time | According to the order q’ty |

| OEM& ODM | Technical drawing or sample is needed |

Company Profile

ABOUT US

Haibite was set up in 1996 and located at HangZhou, a beautiful city in China. Our company is bearing manufacturer&bearing distributor. Since it was first established, CHINAMFG was dedicated in research, development and manufacture of bearings. Now, CHINAMFG has become main and 1 of the first grade suppliers of all kinds of bearings. We could develop the products constructed from different materials, structures, shapes, colors etc.

WELCOME TO THE CLUB!

1. Our rollers are in stable quality with smooth rotation, long life operation, small movement, advanced injection technology engineering etc.

2. The Adjustable Rollers with smooth and long lasting operation, higher performing features like wider adjustment ranges, long rolling life performance, easy installment. It’s available in multiple housing choices with any wheels to fit different aluminnum. Our roller ensure alignment across the full adjustment ranges within built-in retention system.

3. The customized hardware, like plastic parts, stamping patrs, cold forging steel patrs are widely applied in the window and doors, furniture, householders, transmission system, industrial drive system etc.

We are constantly improving and striving for excellent service. We hold a very high regard for our customers, the quality of our products, and our level of customer service.

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2017,sell to North America(1.00%),Africa(1.00%),Western Europe(1.00%),Southern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Bearing cage,Bearing pulley,Plastic products,Miniature bearing,Needle roller bearing

4. why should you buy from us not from other suppliers?

Hardware pulley source factory,20 years professional bearing pulley experience

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A;

Language Spoken:English,Chinese,Spanish,Japanese,F

Our Advantages

Sliding glass doors are becoming more and more popular, because of the view and natural lighting that they provide. But there can be some difficulty when it comes to maintaine them, such as the rollers have worn out. The key part is knowing which roller matches the original. Many people believe that alternatives can be found by identifying the door manufacturer individually. Actually, Most rollers are generic and used by various door manufacturers.

As the professional manufacturer of sliding rollers, we use various identifying characteristics to determine the best replacement option for your door. In addition to the number of wheels your roller uses to support the door, the presence of dimples, bumps, cut-outs and flared edges on the rollers housing will narrow down replacement options substantially. The way that the assembly installs in the door frame is also vital. The key dimensions to confirm a replacement include the width and height of the roller’s outer housing, as well as the diameter of the wheel. In addition to the diameter of the wheels, the material that they’re made of, steel or nylon, is also a factor. Long-term, metal wheels are known to hold up better but they can also cause the track to wear out faster, especially on heavy doors. Nylon wheels tend to be kinder to the track but may not last as long as their steel counterparts.

Purchase Notice

1.Pls send us an inquiry or leave us a message, there will be a dedicated staff to serve you within 1 hours.

2.You can ask us to take actual photos of the products for you, and free samples would be provided.

3. Welcome to visit our factory to negotiate orders, we will do our best to protect the safety of your business journey.

4. Packaging can be customized according to customer requirements

Finally, Please be sure to click “Contact supplier” to contact us, or “Call us” with any questions that you may have.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Injection Molding |

| Samples: |

US$ 0.22/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can plastic wheels be customized for specific uses or environments?

Yes, plastic wheels can be customized for specific uses or environments to meet unique requirements and applications. Customization options for plastic wheels include:

- 1. Material Selection: Plastic wheels can be manufactured from various types of plastics, each with specific properties. Depending on the application, you can choose the most suitable plastic material to optimize factors like durability, chemical resistance, temperature tolerance, and load-bearing capacity.

- 2. Load Capacity: Custom plastic wheels can be designed with specific load-bearing capabilities in mind. Reinforcements and modifications to the wheel’s structure can be made to increase its load capacity, ensuring it can handle the intended weight.

- 3. Wheel Diameter: The size and diameter of the wheel can be customized to match the terrain and space constraints of the application. Whether you need smaller or larger wheels, customization is possible to ensure a perfect fit.

- 4. Tread Design: The tread pattern on plastic wheels can be tailored to provide optimal traction, stability, and noise reduction for specific environments. Different tread designs are available to suit various surfaces and conditions.

- 5. Bearings: Custom plastic wheels can be equipped with different types of bearings to meet performance requirements. Precision bearings, sealed bearings, or special bearing configurations can be chosen based on the application’s demands.

- 6. Environment-Specific Features: Plastic wheels can be customized with features like corrosion-resistant coatings, anti-static properties, UV resistance, and non-marking materials to accommodate specific environmental conditions.

- 7. Color and Aesthetics: Custom plastic wheels can be produced in various colors and finishes to match the aesthetics of the equipment or environment they are used in. This is common in applications like office furniture and consumer products.

- 8. Mounting Options: Custom wheels can be designed with specific mounting and attachment options to ensure a secure fit with the equipment or vehicle. Custom hubs or axle configurations can be provided.

- 9. Specialized Applications: For highly specialized applications, such as aerospace, healthcare, or automotive, plastic wheels can be customized to meet stringent industry standards and certifications.

- 10. Prototyping and Testing: Customization often involves prototyping and testing to ensure that the wheels meet the desired performance criteria. Manufacturers can work closely with customers to develop and refine custom wheel designs.

Customized plastic wheels are valuable for industries and applications with specific needs, ensuring that the wheels perform optimally and contribute to the overall functionality and efficiency of equipment or systems.

Can you provide insights into the importance of proper installation and alignment of plastic wheels?

The proper installation and alignment of plastic wheels are crucial for ensuring optimal performance, safety, and longevity in various applications. Here are key insights into their importance:

- 1. Load Distribution: Correct installation ensures that the weight load is evenly distributed across all wheels. Proper weight distribution prevents overloading of individual wheels, reducing the risk of premature wear and potential wheel failure.

- 2. Reduced Friction: Properly aligned wheels minimize friction and rolling resistance. Misalignment can result in increased friction, requiring more effort to move equipment or objects. This can lead to reduced efficiency and increased wear on the wheels.

- 3. Improved Maneuverability: Properly aligned wheels provide better maneuverability and control. Whether in industrial settings or everyday use, aligned wheels allow for smooth and precise movement, enhancing productivity and safety.

- 4. Floor Protection: Aligning wheels correctly helps protect flooring surfaces. Misaligned or unevenly loaded wheels can cause floor damage, such as scuffs, scratches, or dents, which can be costly to repair.

- 5. Enhanced Stability: Proper alignment contributes to the stability of equipment and vehicles. Misaligned wheels can result in wobbling or instability, posing safety hazards and potentially causing accidents or damage.

- 6. Longevity: Proper installation and alignment extend the service life of plastic wheels. Misalignment can lead to uneven wear, reducing the lifespan of the wheels and necessitating premature replacements.

- 7. Noise Reduction: Misaligned wheels can generate noise due to uneven rolling. Proper alignment minimizes noise pollution, making plastic wheels suitable for applications where quiet operation is essential.

- 8. Safety: Ensuring that wheels are correctly installed and aligned is crucial for safety. Misalignment or improper installation can lead to accidents, equipment failure, and injuries, especially in industrial and automotive settings.

- 9. Maintenance Efficiency: Properly aligned wheels are easier to maintain. Routine inspections and maintenance tasks are more straightforward when wheels are aligned, reducing downtime and maintenance costs.

- 10. Performance Consistency: Correct alignment results in consistent performance. This is essential for applications where precision and repeatability are critical, such as conveyor systems or automated machinery.

In summary, proper installation and alignment of plastic wheels are fundamental to their functionality and performance. They contribute to load distribution, reduced friction, improved maneuverability, floor protection, stability, longevity, noise reduction, safety, maintenance efficiency, and performance consistency. Neglecting alignment can lead to various issues that impact efficiency, safety, and the overall quality of operations.

What are the different types and sizes of plastic wheels available in the market?

The market offers a variety of plastic wheels, each designed for specific applications and available in various sizes. Here are different types and sizes of plastic wheels commonly available:

- 1. Caster Wheels: Caster wheels are used for mobility and swiveling in a wide range of applications. They come in sizes ranging from small, furniture casters to large, heavy-duty industrial casters.

- 2. Hand Truck Wheels: These wheels are commonly used on hand trucks and dollies for moving heavy loads. They are available in sizes such as 8-inch, 10-inch, and 12-inch diameters.

- 3. Trolley Wheels: Trolley wheels are used on material handling carts and trolleys. They come in various sizes, including 4-inch, 5-inch, and 6-inch diameters.

- 4. Lawnmower Wheels: These wheels are designed for lawnmowers and other outdoor equipment. They are available in sizes like 8-inch, 10-inch, and 12-inch diameters.

- 5. Office Chair Casters: Office chair casters come in different sizes to fit various chair bases. Common sizes include 2-inch, 2.5-inch, and 3-inch diameters.

- 6. Heavy-Duty Industrial Wheels: These wheels are used in industrial and manufacturing settings. They are available in larger sizes, such as 6 inches, 8 inches, and even up to 12 inches or more in diameter.

- 7. Skateboard Wheels: Plastic skateboard wheels come in various sizes, typically ranging from 50mm to 60mm in diameter, with different hardness levels for different riding styles.

- 8. Conveyor Wheels: Conveyor wheels are used in material handling and conveyor systems. They come in sizes suitable for specific conveyor designs and loads.

- 9. V-Groove Wheels: V-groove wheels are designed for use on tracks or grooves. They come in sizes suitable for different track profiles and load capacities.

- 10. Trailer Jack Wheels: Trailer jack wheels are used for trailer jacks and stabilizers. They come in sizes such as 6-inch, 8-inch, and 10-inch diameters.

- 11. Light-Duty Wheels: These wheels are used in various light-duty applications, such as small carts and furniture. They are available in sizes ranging from 1 inch to 6 inches in diameter.

- 12. Specialized Wheels: Some plastic wheels are designed for specific applications, such as luggage wheels, boat trailer rollers, and gate wheels. Their sizes vary depending on the intended use.

The availability of plastic wheels in different types and sizes allows them to cater to a wide range of industries and applications. When selecting a plastic wheel, it’s essential to consider factors like load capacity, wheel diameter, tread design, and material to ensure it meets the requirements of the specific use case.

editor by Dream 2024-04-30